Aluminum alloy material with high-precision super-smooth surface, polishing disk, polishing agent and polishing method

A technology for aluminum alloy materials and ultra-smooth surfaces, which can be applied to polishing compositions containing abrasives, manufacturing tools, and metal processing equipment. Fixed-point quantitative removal of materials, difficulty in obtaining high-precision ultra-smooth surfaces, etc., to achieve optimal polishing effect, improve surface quality, and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] a kind of like Figure 6 and Figure 7 As shown in the aluminum alloy material with high-precision ultra-smooth surface of the present invention, the roughness Ra of the aluminum alloy material is 1.563nm, and the RMS value of the surface shape of the aluminum alloy material is 0.088λ.

[0039] The above-mentioned aluminum alloy material with high-precision ultra-smooth surface in this embodiment is obtained by the following polishing method, which specifically includes the following steps:

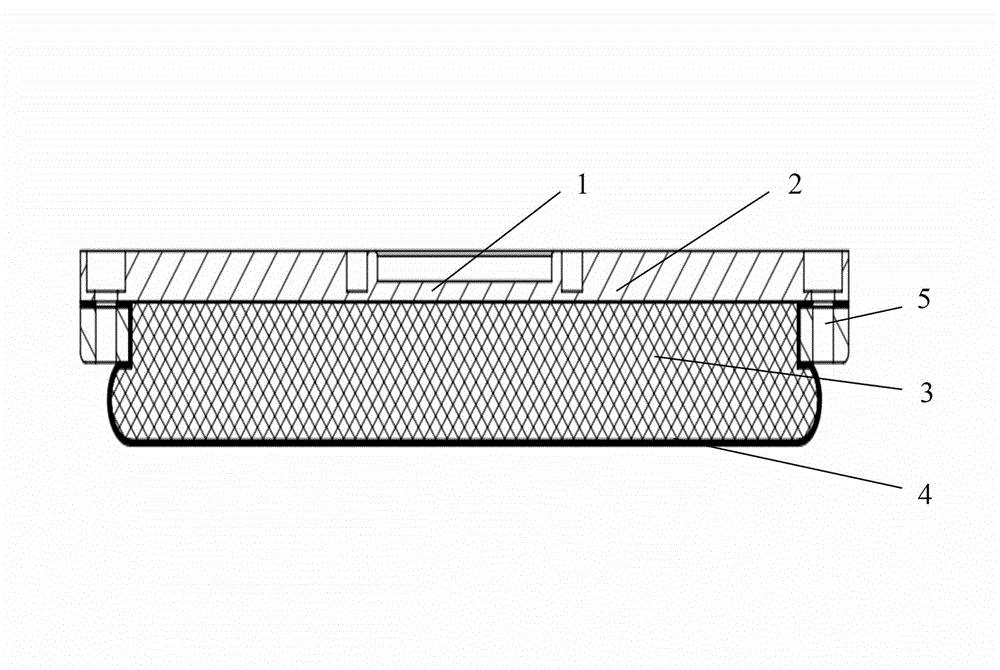

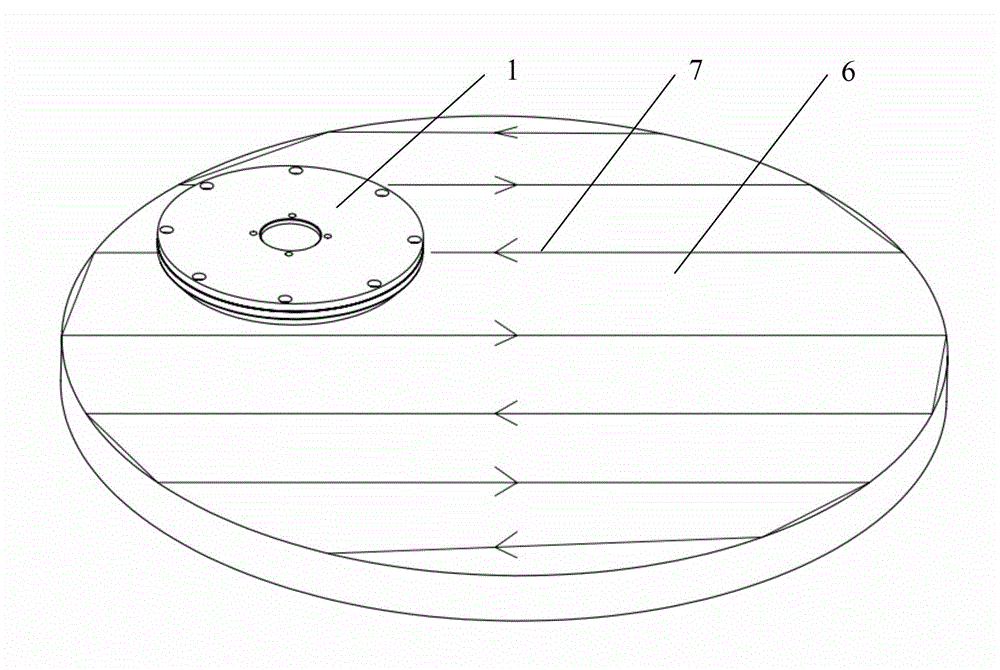

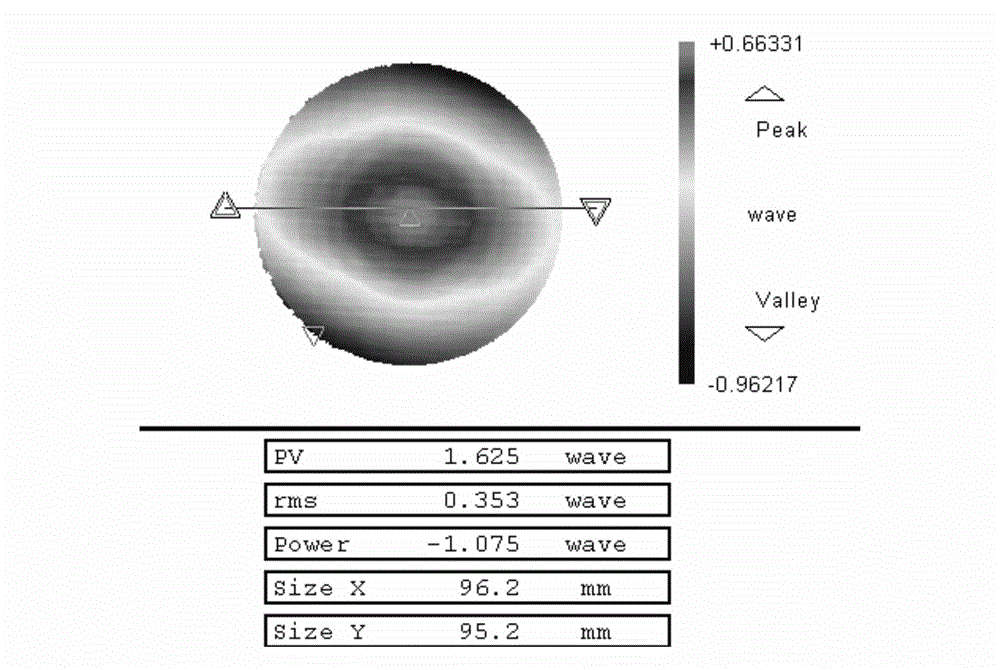

[0040] 1. One-time polishing: Prepare the aluminum alloy material to be polished, and firstly use the conventional single-point diamond turning process to polish the surface of the aluminum alloy material once to obtain a rough-processed aluminum alloy surface; measure the rough-processed surface on a laser interferometer Surface shape distribution of the aluminum alloy surface, the measurement results are as follows image 3 shown by image 3 It can be seen that the surface sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com