Apparatus and methods for packaging a product

a technology for packaging products and apparatuses, applied in the field of packaging machines, can solve the problems of limiting the maximum length of the product to be packaged, affecting the product quality of the product, so as to achieve the effect of increasing the speed of the machine, reducing the duration of the process, and being more versatil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

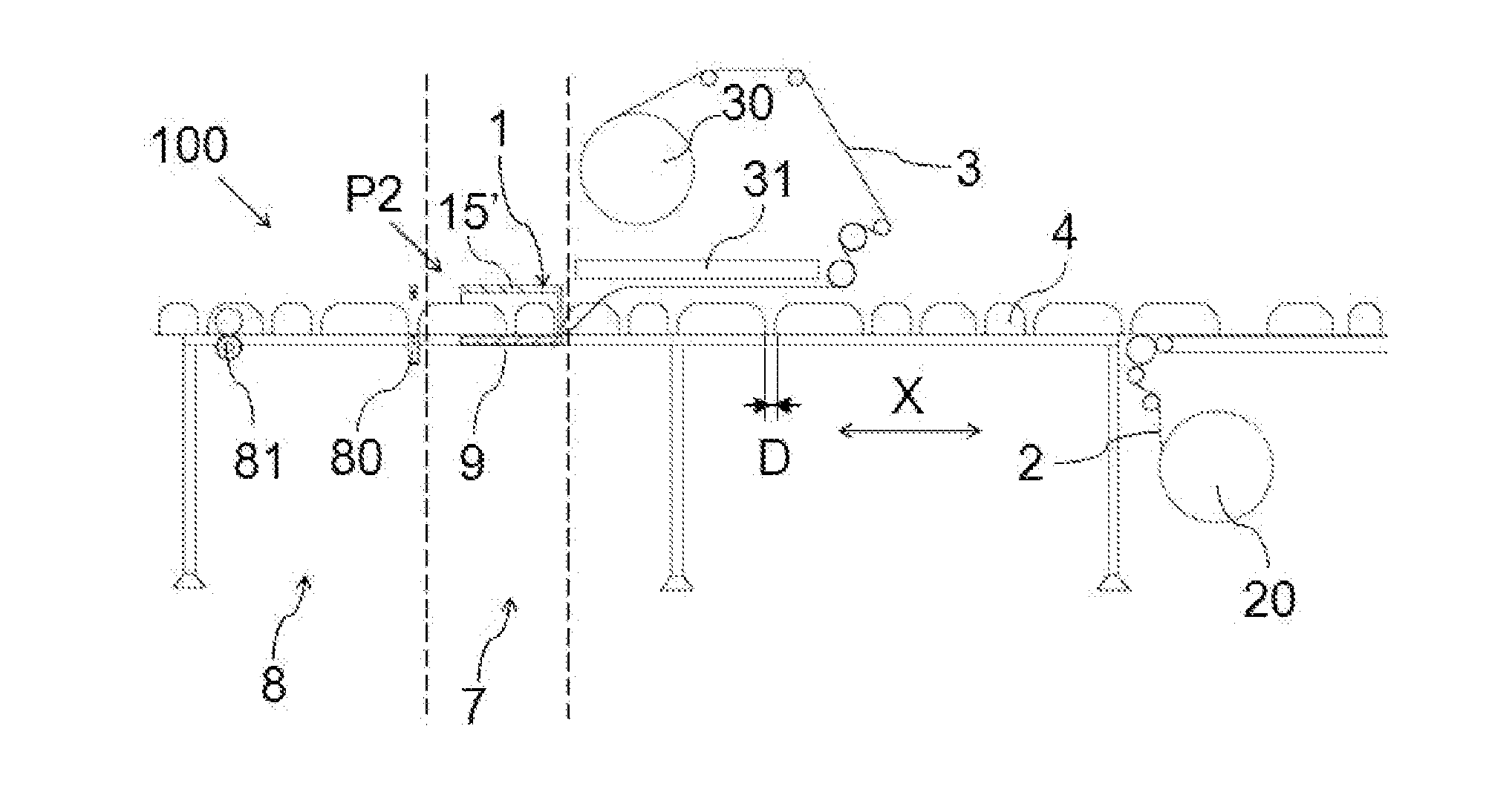

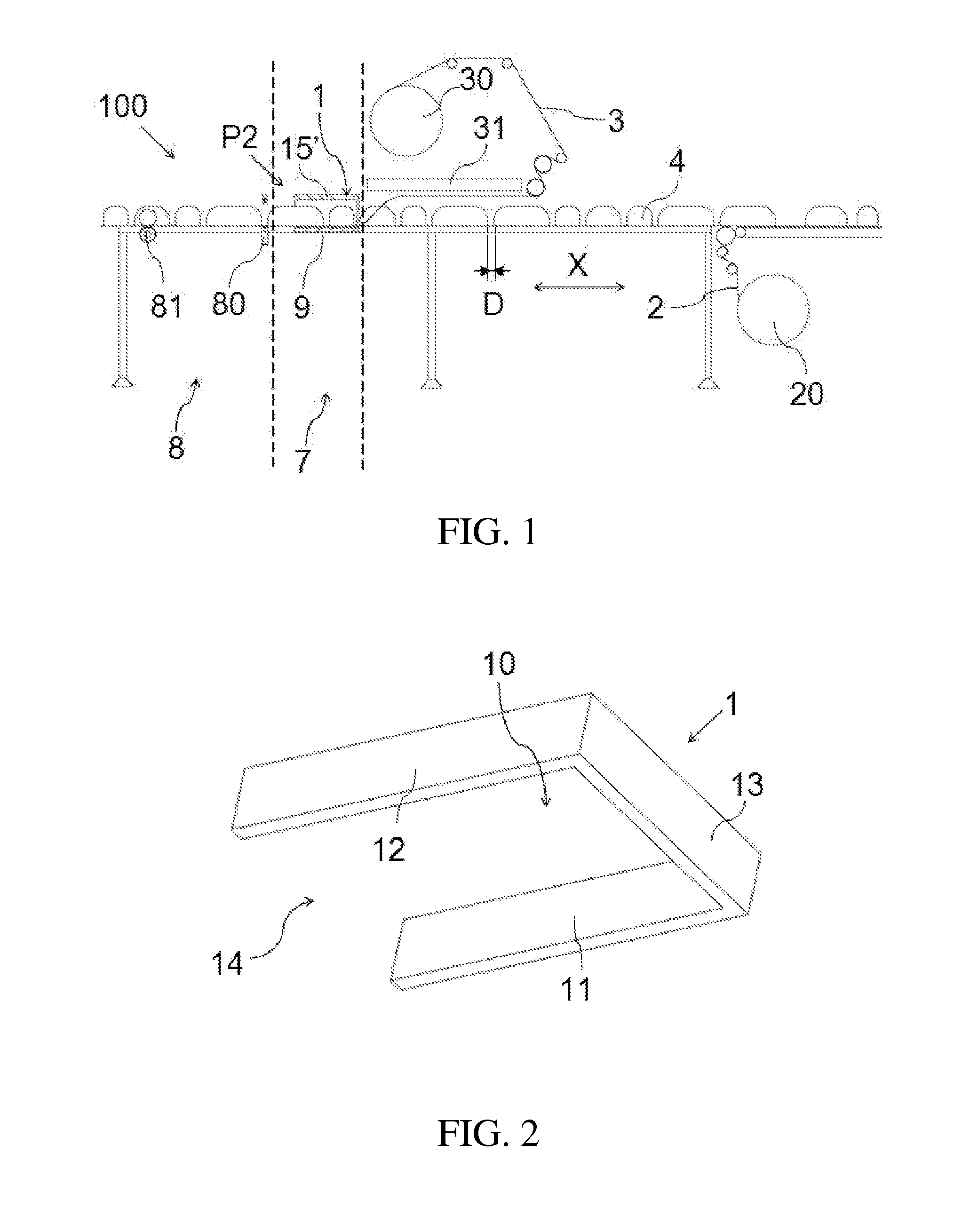

[0030]In the machine 100, the sealing member 1 corresponds with a sealing mould 1 and comprises a substantially U-lying shape, as shown in FIG. 2. When the sealing member 1 moves towards the sealing tool 9, the product 4 is disposed in a sealed space defined by the inner space 10 and the previously packaged product 4, thereby enabling the sealing of the films 2 and 3 around the product 4 by means of at least one lower vacuum and heat.

[0031]In a first configuration of the first embodiment the transverse wall 13 of the sealing member 1 is fixed in relation to the longitudinal walls 11 and 12.

[0032]In a second configuration of the first embodiment, the transverse wall 13 of the sealing member 1 is mobile in relation to the longitudinal walls 11 and 12. The second configuration is adapted for the case in which the products are supplied in an intermittent manner with a constant advance, and instead of moving the sealing member 1 in the advance direction X to be adapted to the different l...

second embodiment

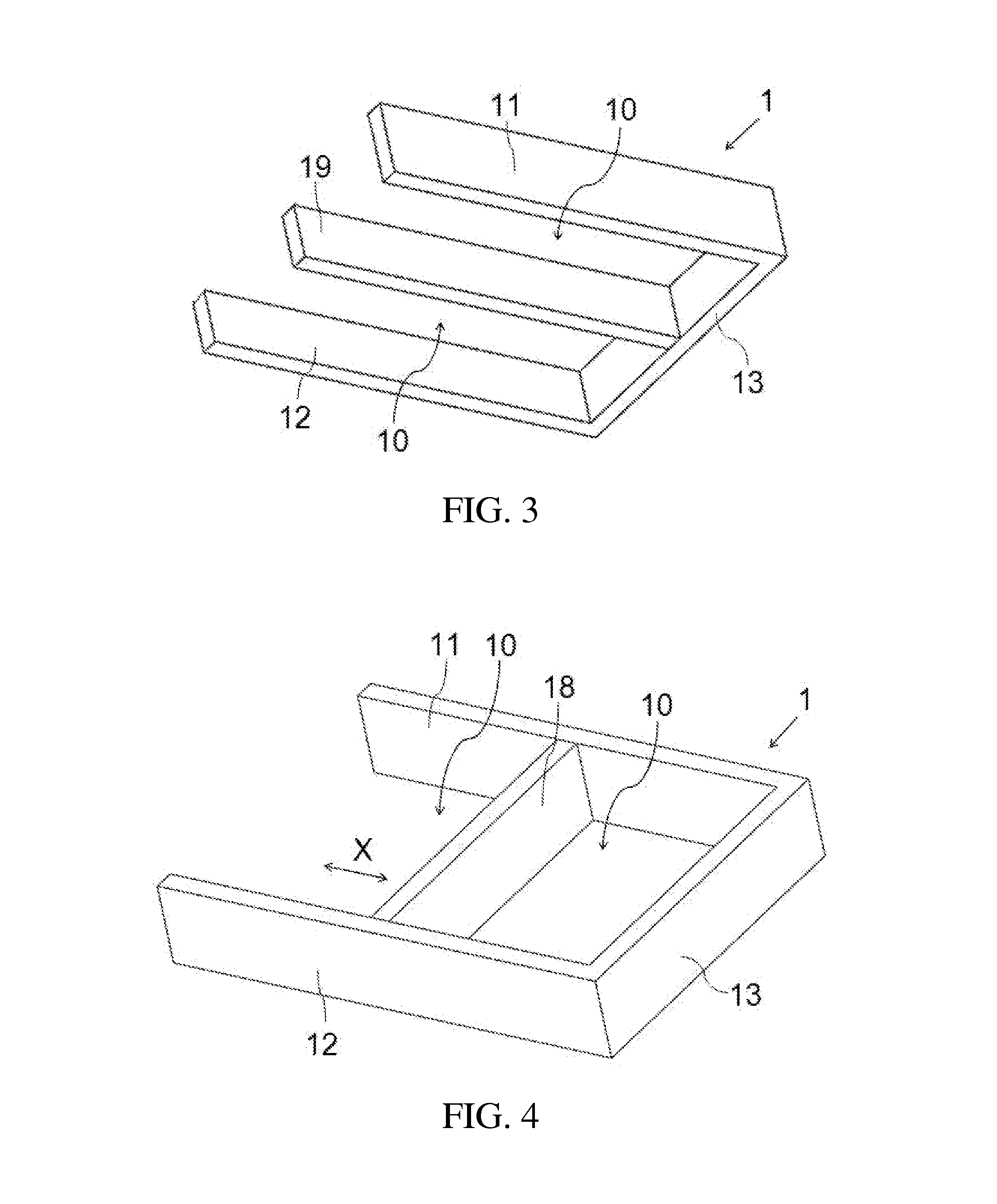

[0033]In the machine 100 the sealing member 1 comprises, in addition to the walls 11, 12 and 13, at least one intermediate longitudinal wall 19 that is disposed between the longitudinal walls 11 and 12, which comprises a length substantially equal to the length of the longitudinal walls 11 and 12, and which is substantially parallel to the longitudinal walls 11 and 12, as shown in the example of FIG. 3. With the intermediate longitudinal wall 19 the sealing member 1 defines at least two inner spaces 10 disposed in parallel, a product 4 being disposed in each inner space 10 in order to be vacuum-packaged between both films 2 and 3. As a result, two or more products 4 may be packaged simultaneously in a single machine 100. The inner spaces 10 are separated from each other by intermediate longitudinal walls 19, the sealing member 1 comprising a substantially inverted E shape when it defines two inner spaces 10 and so on.

[0034]In a first configuration of the second embodiment, the inter...

third embodiment

[0036]In the machine 100 the sealing member 1 comprises, in addition to the walls 11, 12 and 13, at least one additional transverse wall 18 that is disposed transversally between the longitudinal walls 11 and 12, which comprises a length substantially equal to the length of the transverse wall 13, and which is substantially parallel to the transverse wall 13, as shown in the example of FIG. 4. With the additional transverse wall 18 the sealing member 1 defines at least two inner spaces 10 disposed in series, a product 4 being disposed in each inner space 10 to be vacuum-packaged between both films 2 and 3. As a result, two or more products 4 may be packaged simultaneously in a single machine 100. The inner spaces 10 are separated from each other by additional transverse walls 18.

[0037]In a first configuration of the third embodiment, the additional transverse wall 18 is mobile in relation to the longitudinal walls 11 and 12 in the advance direction X, as is the case in the second co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com