Clamping Retractor Assembly

a retractor and assembly technology, applied in the field of retractor assemblies, can solve the problems of unsatisfactory free end cantilever, complex mechanism that may need to be employed, and the stability of the retractor may also be a problem, so as to improve the mechanical advantage of the retractor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072]The examples referred to herein are illustrative and are not to be regarded as limiting the scope of the invention. While various embodiments of the invention have been described herein, it will be appreciated that these are capable of modification, and therefore the disclosures herein are not to be construed as limiting of the precise details set forth, but to avail such changes and alterations as fall within the purview of the description.

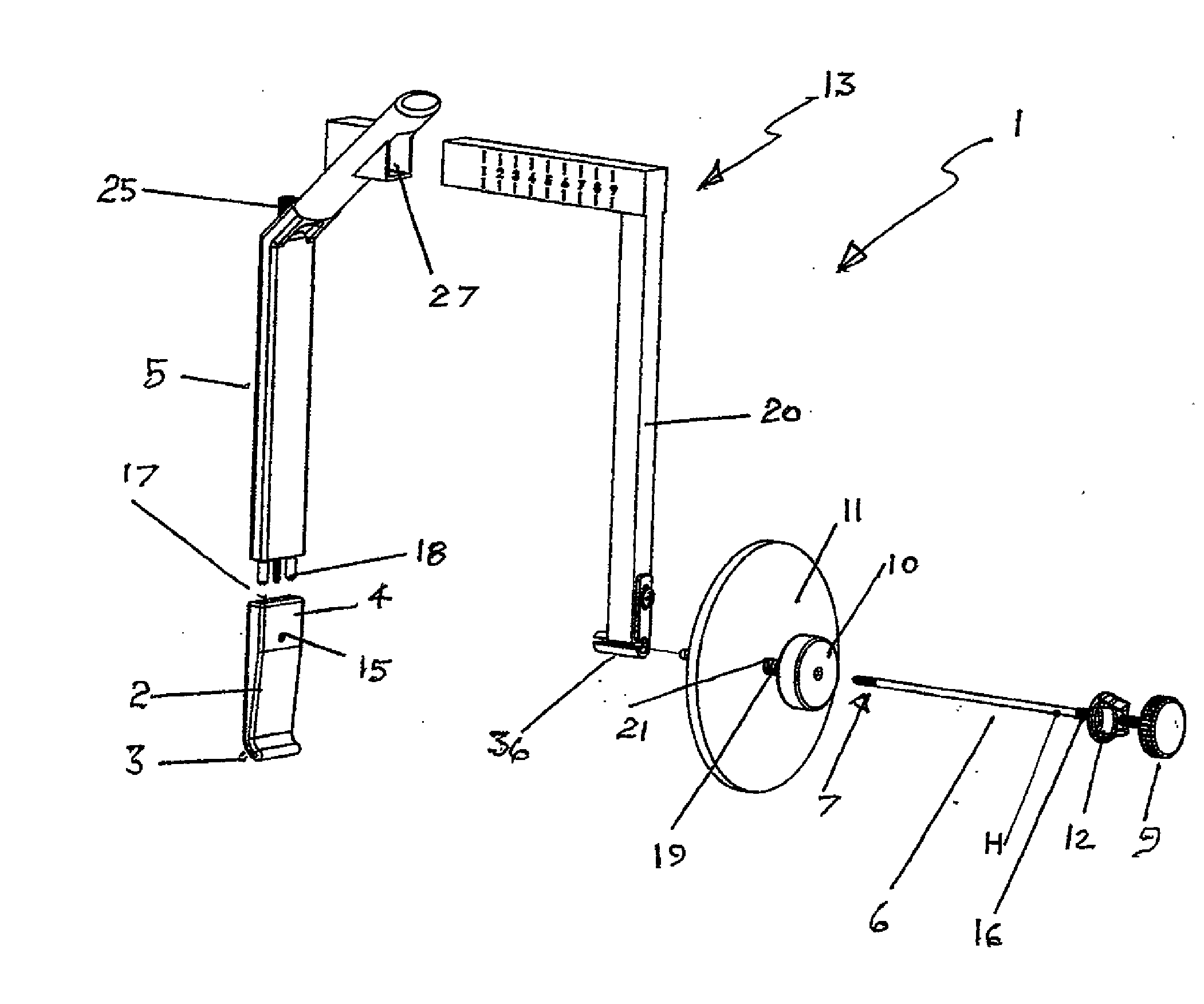

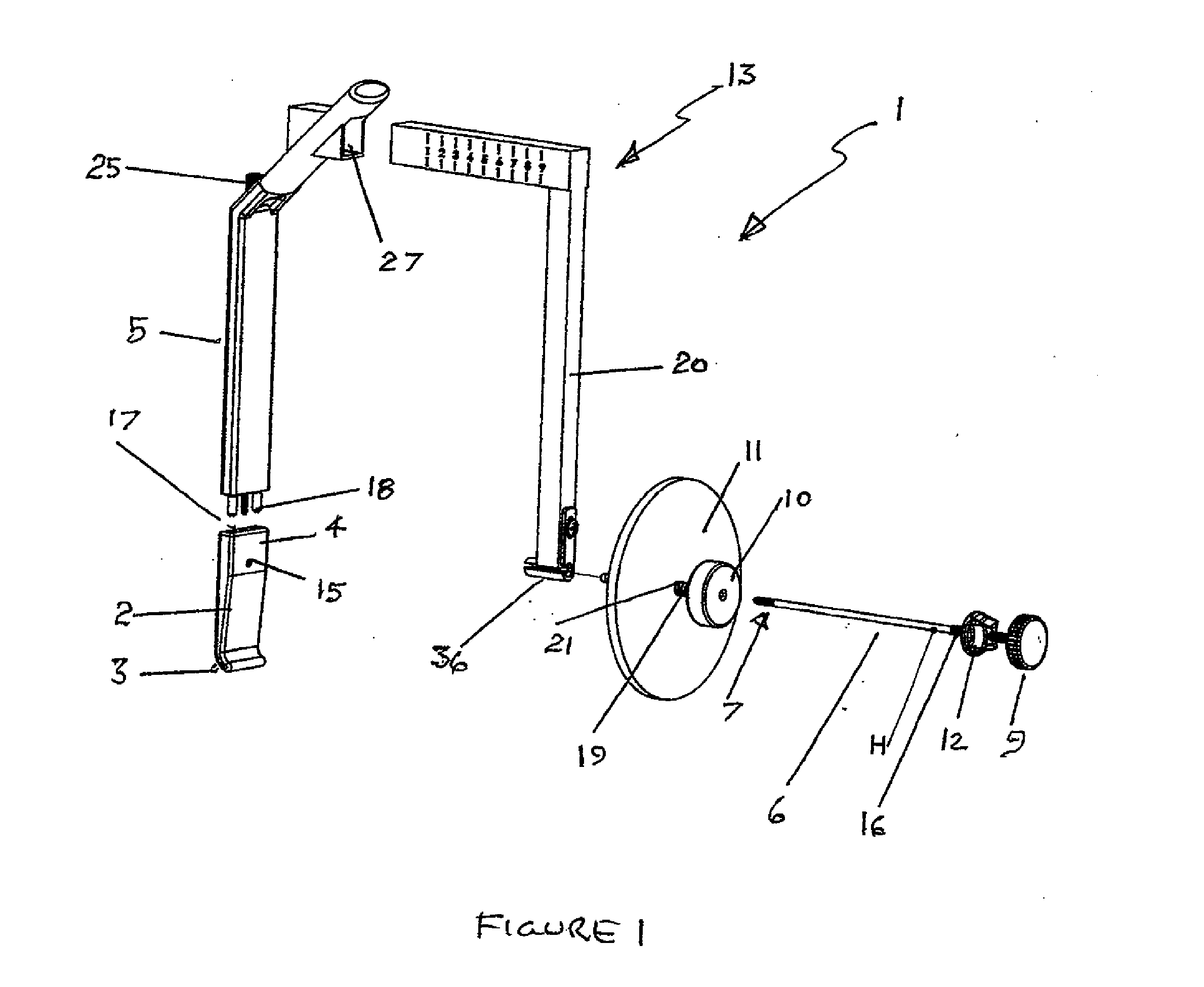

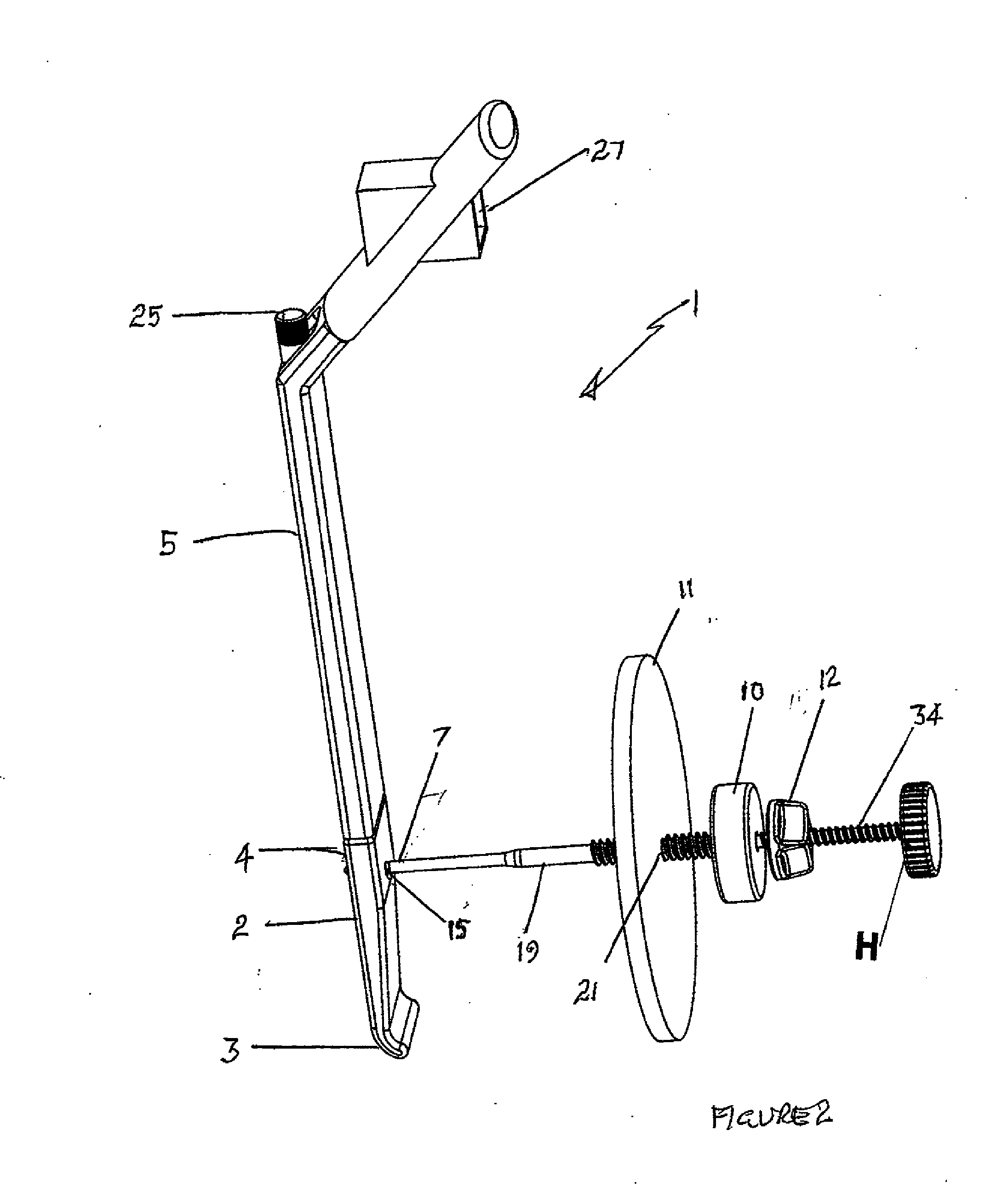

[0073]FIG. 1 shows a perspective view of a retraction assembly 1 according to one embodiment. Assembly 1 for refracting soft tissue in a surgical wound comprises a retractor blade 2 having a first distal end 3 and a second end 4 which includes an associated handle 5. Assembly 1 further comprises a one piece trochar handle 6 having a pointed tip first end 7 which engages blade 2 and a second end 8 which includes a manual operating control element 9. Intermediate therebetween is adjustable stop 10 which engages a plate 11, wherein the plate e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com