Lubrication control apparatus for vehicle in-wheel motor unit

a technology of lubrication control apparatus and in-wheel motor unit, which is applied in the direction of machine/engine, lubrication of auxiliaries, transportation and packaging, etc., can solve the problem of difficult to make a sound shielding countermeasure, and achieve the effect of worsening electric power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Structure of a First Embodiment

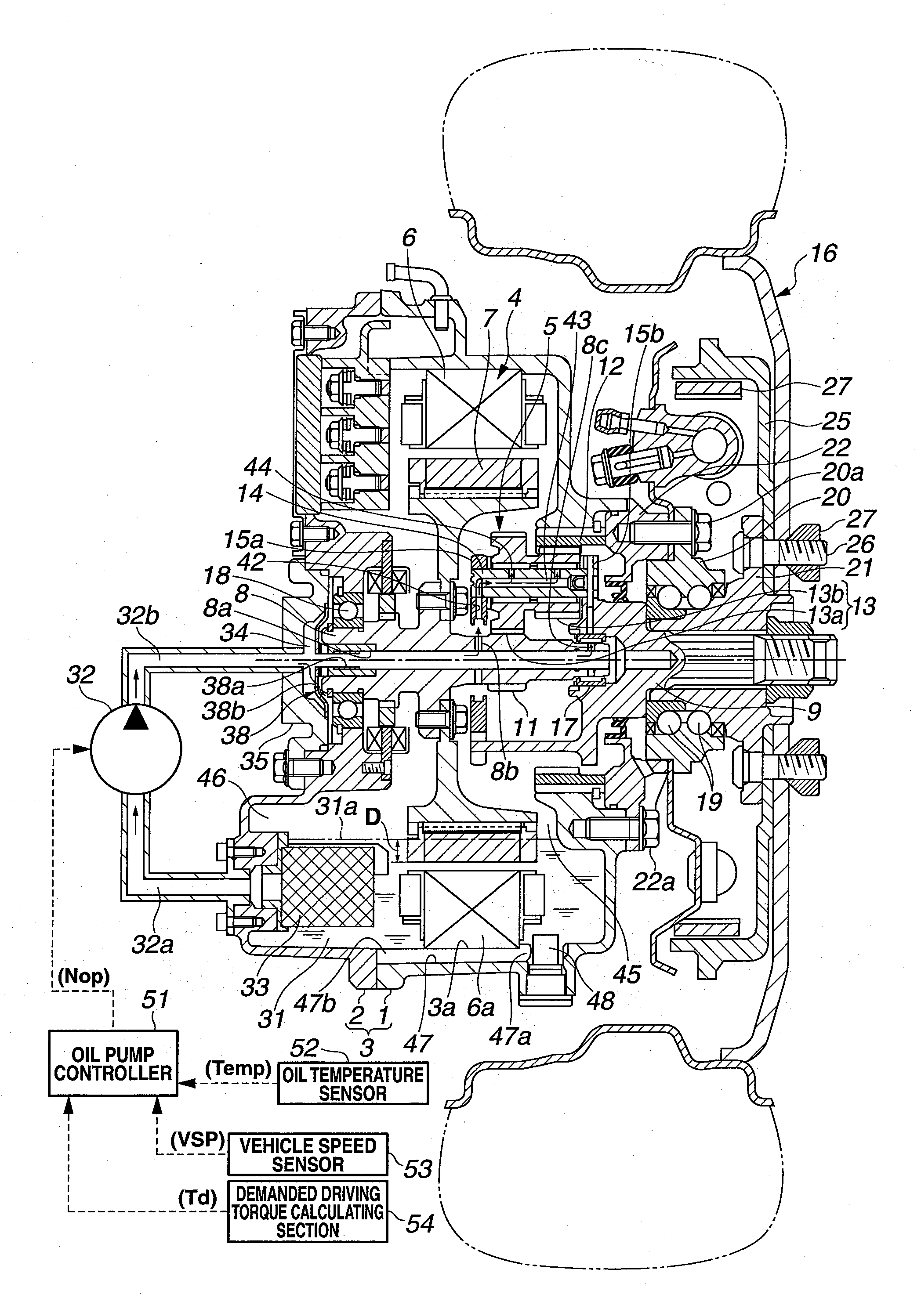

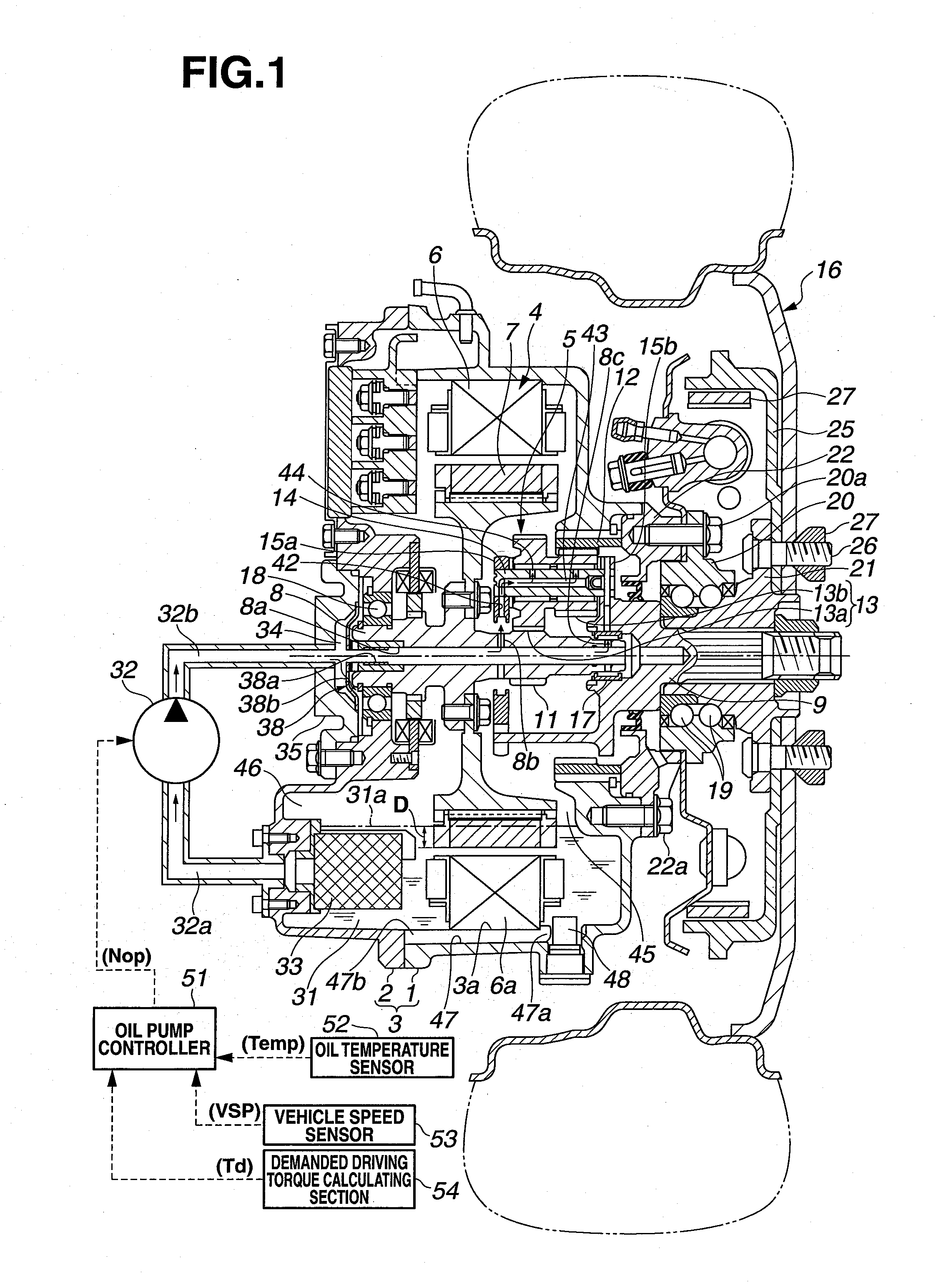

[0027]FIG. 1 shows a longitudinal cross sectional side view representing an in-wheel motor unit in which a lubrication control apparatus in a first preferred embodiment according to the present invention is equipped.

In FIG. 1, reference numeral 1 denotes a case main frame of an in-wheel motor unit, reference numeral 2 denotes a rear cover of a case main frame 1, a unit case 3 of an in-wheel motor unit is formed by means of a mutual uniting of a case main frame 1 and a rear cover 2.

[0028]In-wheel motor unit shown in FIG. 1 houses an electrically driven motor 4 and a planetary gear type speed reduction gear set 5 (hereinafter, referred simply as to a speed reduction gear set) within a unit case 3. Electrically driven motor 4 includes: an annular stator 6 which is fitted to an inner circumferential portion of case main frame 1 to be fixed; and a rotor 7 concentrically arranged onto an inner circumferential portion of annular stator 6 with a radial gap.

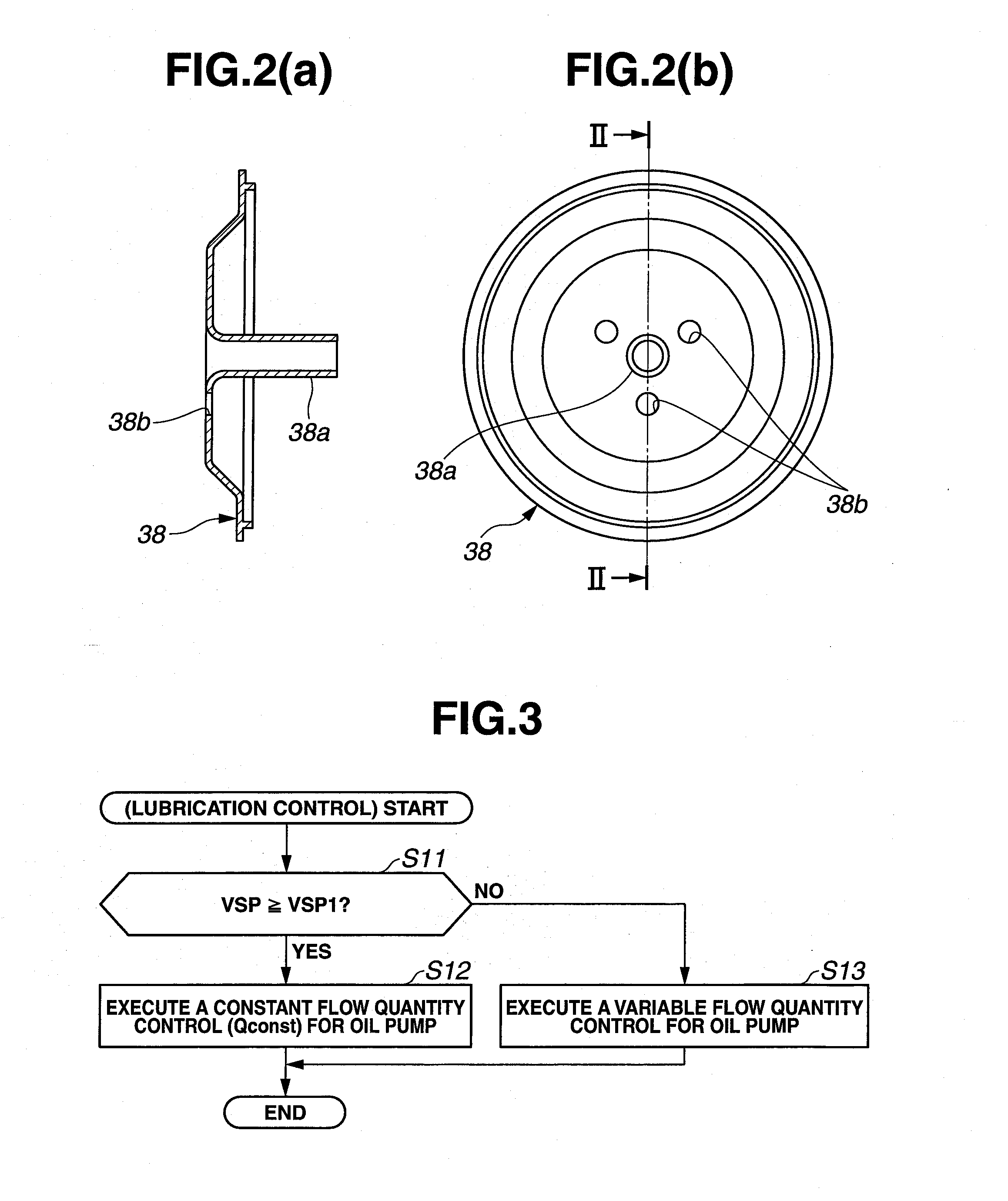

[00...

second embodiment

Structure of a Second Embodiment

[0101]Next, referring to FIG. 11, a second preferred embodiment according to the present invention will be described with reference to FIGS. 1 to 10. It should be noted that the explanation of a part or parts common to the above-described first embodiment will suitably be omitted.

[0102]In this second embodiment, above-described setting torque ΣTdm is a lower limitation value of demanded driving torque Td required to activate (each) oil pump 32 from the vehicle stopped state. Since ΣTd≧ΣTdm, oil suction and supply quantity Q0 during the vehicle stopped state shown in FIG. 5 in a case where oil pump(s) 32 is activated from the vehicle stopped state is made correspondence to the lubrication oil quantity required for the in-wheel motor unit due to the presence of demanded driving torque Td at the time of the vehicle stopped state. Thus, as demanded driving torque Td (its integration value ΣTd) becomes larger (in more details, as a torque difference ΣTd−ΣT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com