Method and apparatus for controlling turbine efficiency

a turbine efficiency and turbine technology, applied in mechanical equipment, electric control, machines/engines, etc., can solve the problems of fuel and emission penalty, turbo speed, max cylinder pressure, compressor temperature, etc., to achieve optimal use of turbo efficiency, increase the controllability of the engine, and wide operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

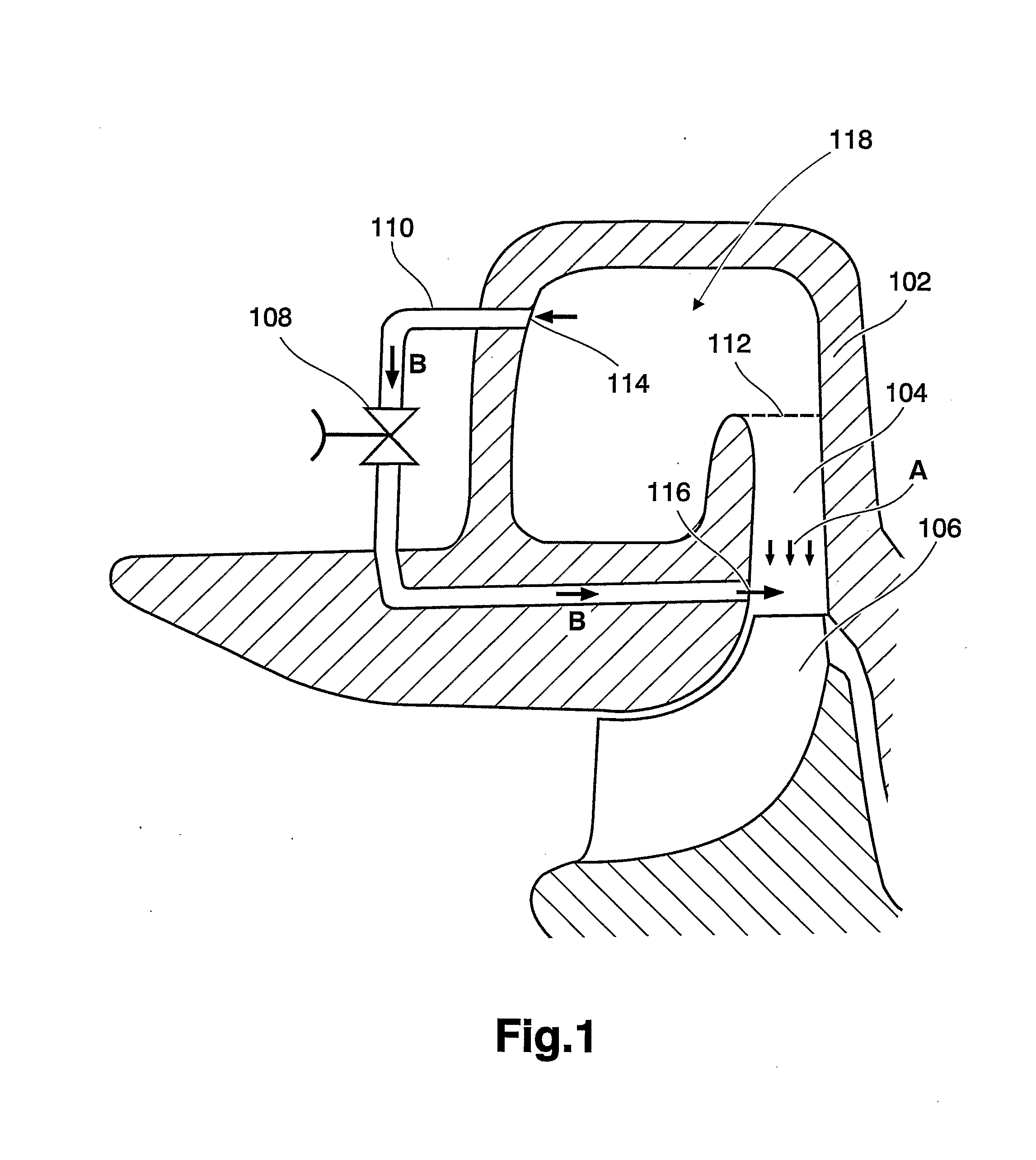

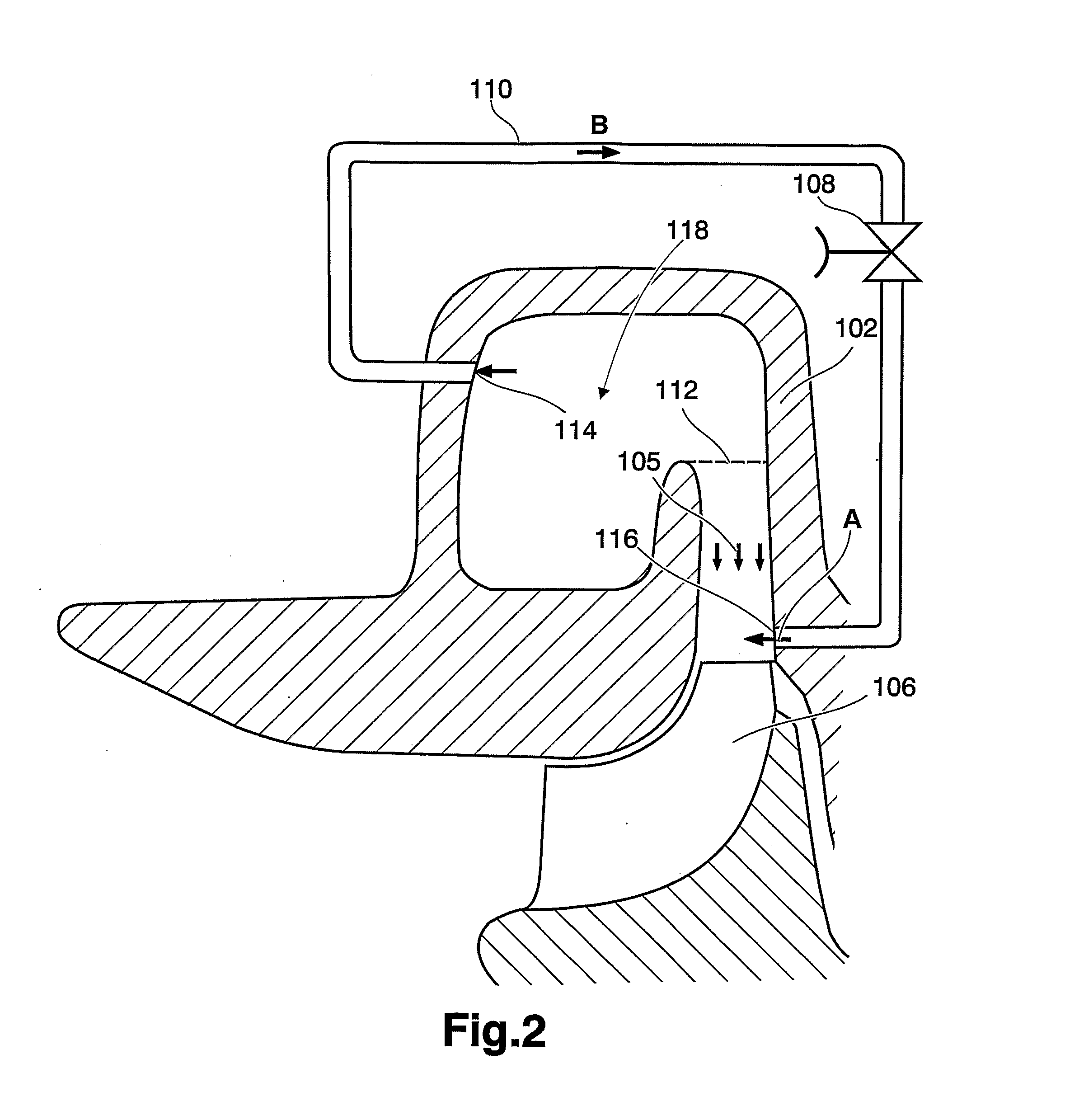

[0037]FIG. 1-5 depicts cross sections of a part of a turbo unit according to different example embodiments of the present invention. FIG. 1 depicts a volute housing 102, a vane 104, a turbine rotor 106, valve 108, pipe 110, gas flow inlet 114, gas flow outlet 116, volute 118. The volute housing 102 is part of the complete turbo unit housing, which also inter alia comprises a bearing housing and a compressor housing, which are not illustrated in FIG. 1-5. The turbo unit housing is in the present context defined as any part which make up the complete turbo unit.

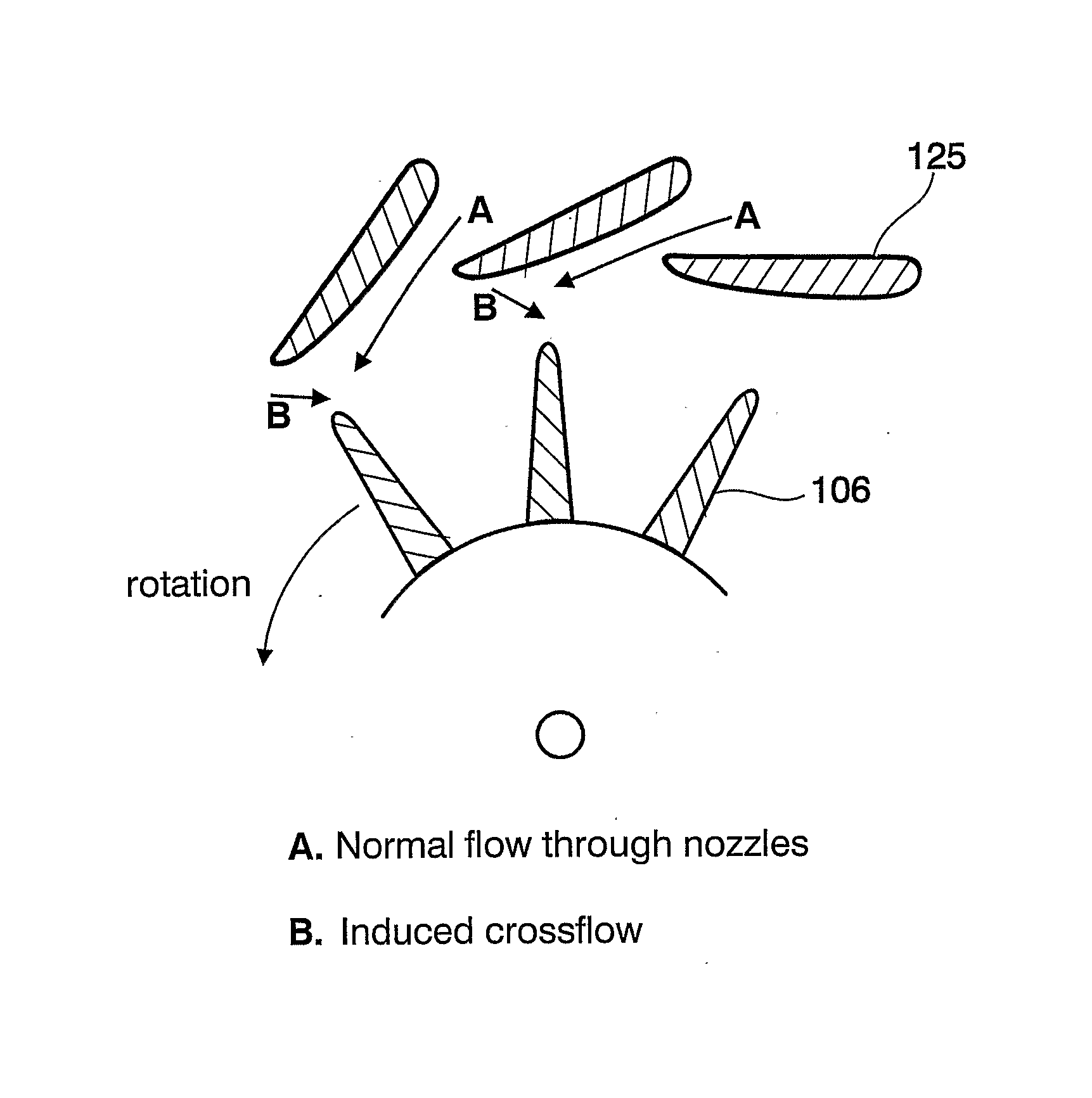

[0038]Exhaust gas from an internal combustion engine flows into the volute 118 in a direction indicated by arrows A in FIG. 1-5. When exhaust gas is passing the turbine 106 said turbine starts to rotate. The embodiment in FIG. 1 is also provided with adjustable vanes 104 for increasing or decreasing the flow of exhaust gas through the turbine. A flow of gas is provided by an outlet 116 which is arranged in a turbine scroll area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com