System and method for providing a reflective insulation layer

a reflective insulation and layer technology, applied in the field of insulation layers, can solve the problem that the layer of conventional reflective insulation systems does not structurally accommodate vapor transmission, and achieve the effect of not facilitating the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]In describing particular features of different embodiments of the present invention, number references will be utilized in relation to the figures accompanying the specification. Similar or identical number references in different figures may be utilized to indicate similar or identical components among different embodiments of the present invention.

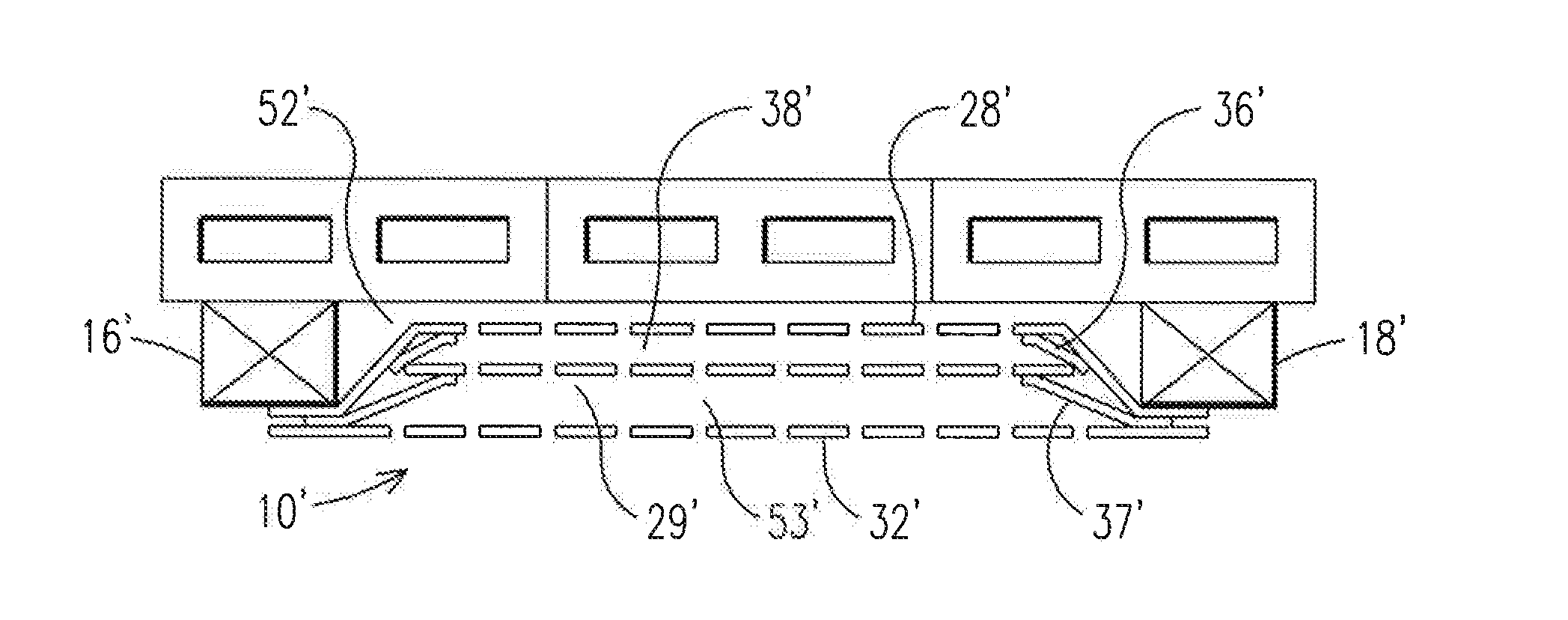

[0015]FIG. 1 illustrates a reflective insulation layer 10 for a structure 12. The structure 12 includes a wall 14 with a plurality of horizontally spaced-apart strips (or vertically oriented) 16,18 and vertically spaced apart strips (or horizontally oriented) 20,22. The horizontally spaced-apart strips 16,18 extend along the wall 14 from a top portion 24 of the wall 14 to a bottom portion 26 of the wall 14. In an exemplary embodiment, the horizontally spaced-apart strips 16,18 and / or vertically spaced-apart strips may be spaced by 16″ or 24″, as appreciated by one of skill in the art. Although FIG. 1 illustrates that the wall 14 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| TD heat shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com