Coating device having coated transmitter coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

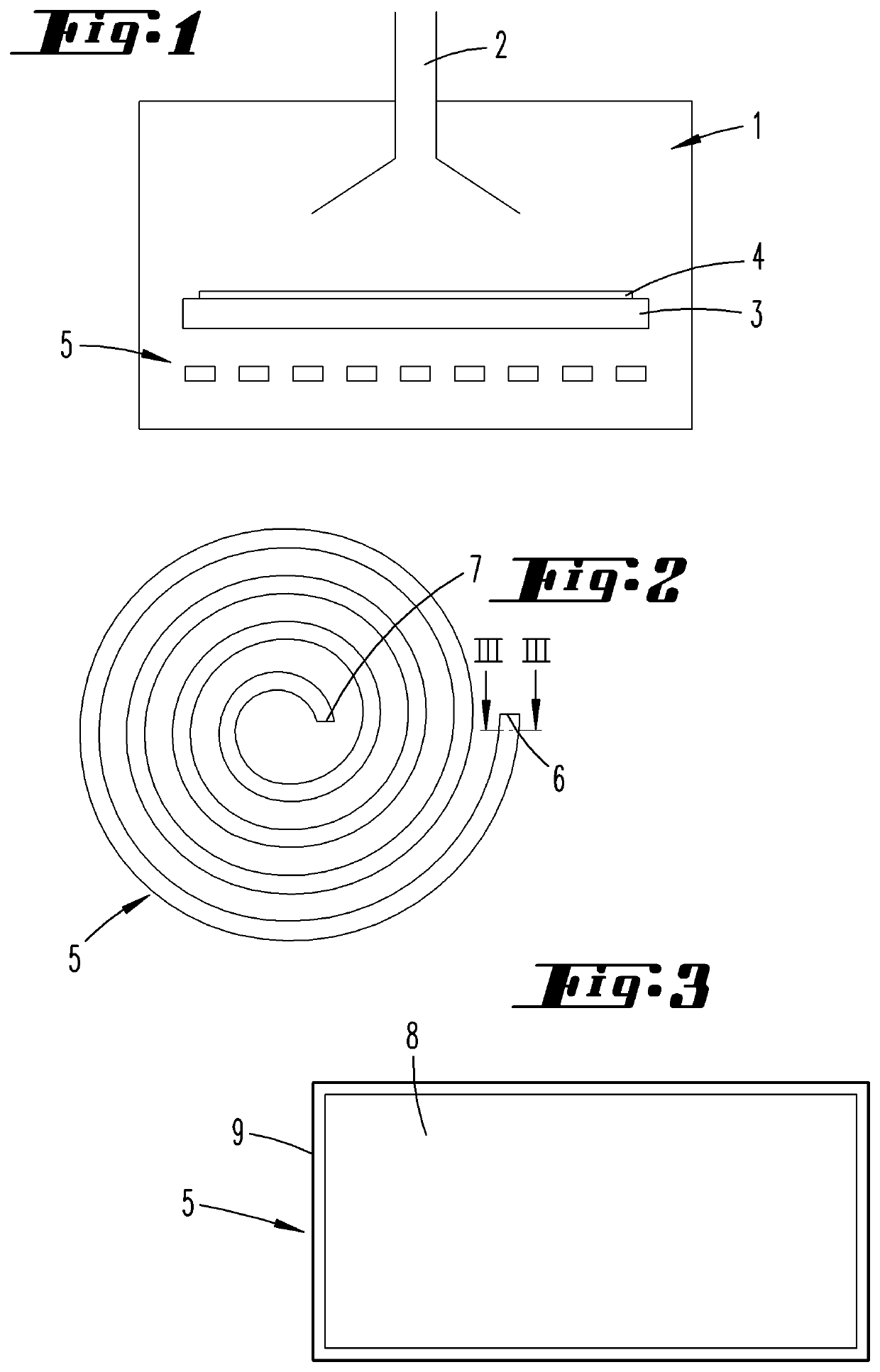

[0015]A gas-tight housing surrounds a process chamber 1, into which a gas inlet device 2 opens, through which (besides other precursors) chlorine-containing gases, for example chlorine-containing compounds of elements of the III-main group, are also supplied. However, other chlorine-containing compounds can also be supplied through the gas inlet device 2, for example so as to clean the process chamber 1 after a coating process by means of an etching step. Here Cl2 or HCl in particular can be considered as the gases.

[0016]In the process chamber 1 there is a susceptor 3, which consists of graphite or another electrically conductive material, and which bears one or a plurality of substrates 4, which are to be coated. In particular, they can be coated with a semiconductor layer, and in particular with a III-V semiconductor layer.

[0017]Underneath and in the same process chamber 1 a transmitter coil 5 is located, which is made of metal and has a spiral shape. The transmitter coil 5 has tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com