Infrared stealth material taking leather as base material, and preparation method thereof

A technology of stealth materials and basic materials, which is applied in the field of preparation of materials with infrared stealth functions, to achieve the effects of shortening the preparation cycle, reducing the preparation cost, and reducing the infrared emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

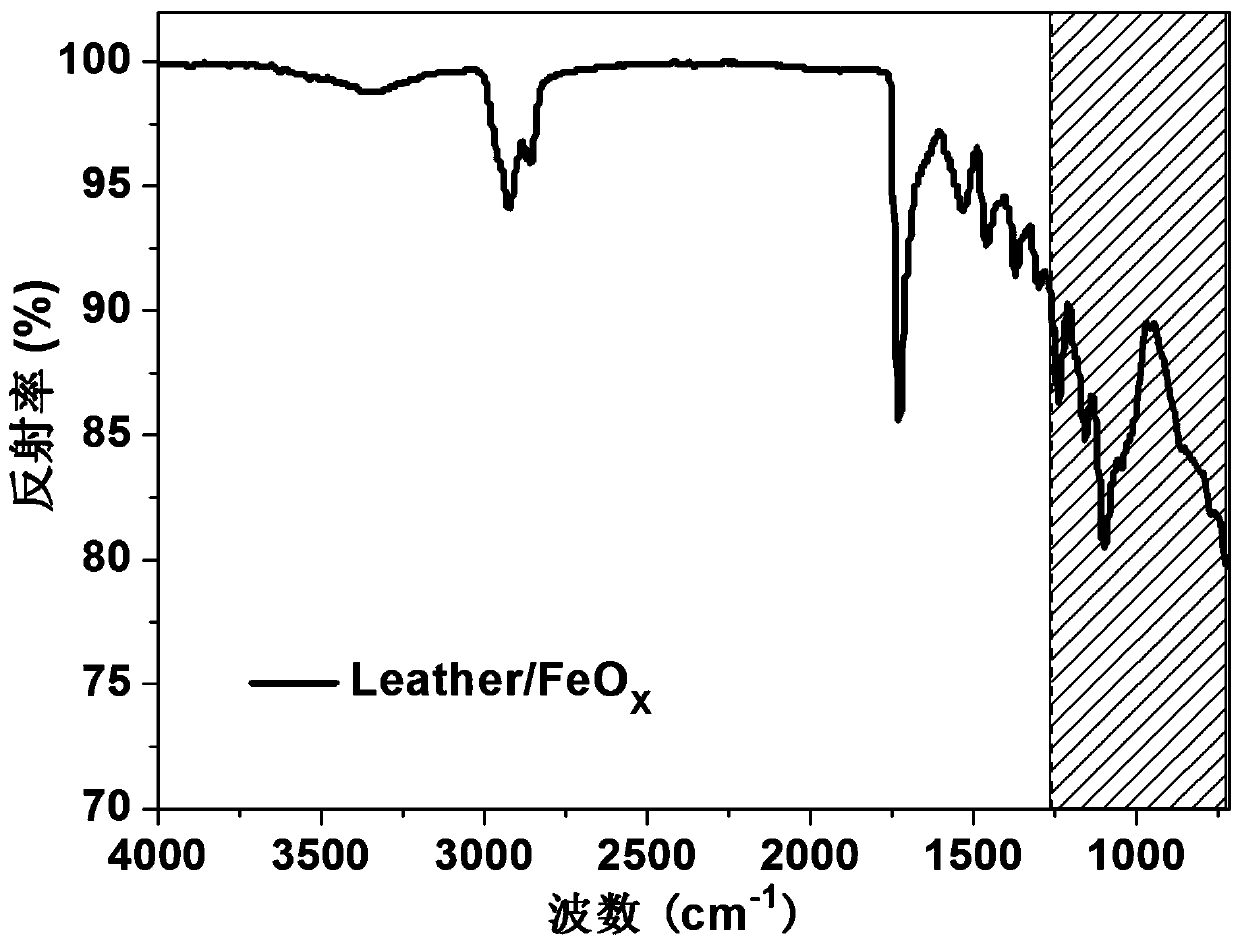

[0047] Take cowhide leather with an area of 20×20 cm, apply 4 g (theoretical spraying amount is 10 mg / cm 2 ) of ferrite FeO X The powder is dispersed in 300 mL of acetone to configure solution A; the polyurethane adhesive with a solid content of 30% (the total solid content of the polyurethane adhesive and FeO X Mix the powder mass ratio of 0.6:1) with 150 mL of acetone to prepare solution B; after mixing solution A and solution B evenly, spray it on the surface of the taken cowhide leather at room temperature, and dry it to obtain infrared stealth. Leather Leather / FeO X . According to the test of Fourier transform infrared spectrometer, it can be known that Leather / FeO X Can reflect at least 80% of infrared waves with a wavelength of 8-14 μm (wavenumber 1250-714 cm -1 ),Such as figure 1 shown. It can be seen that the Leather / FeO X It has strong reflectivity to thermal infrared rays, thereby reducing heat absorption and reducing its own infrared radiation intensity. ...

Embodiment 2

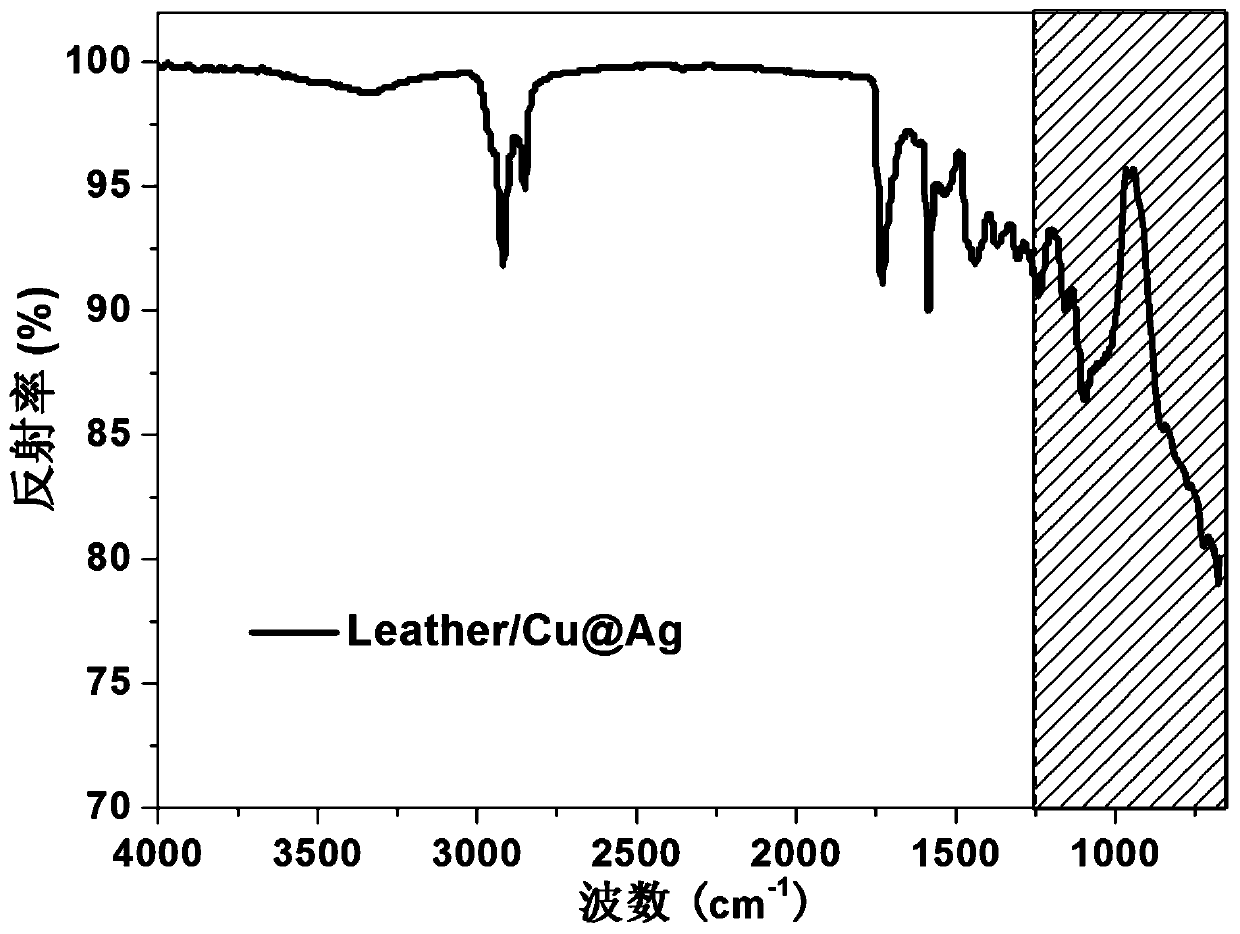

[0049] Take cowhide leather with an area of 20×20 cm, spray 8 g (theoretical spraying amount is 20 mg / cm 2 ) silver-coated copper Cu@Ag powder was dispersed in 600 mL of acetone to configure solution A; a polyurethane adhesive with a solid content of 30% (the mass ratio of PU total solid content to Cu@Ag powder was 3:1) was mixed with 150 mL of acetone was mixed to prepare solution B; after mixing solution A and solution B evenly, it was sprayed on the surface of the obtained cowhide leather at room temperature, and dried to obtain leather Leather / Cu@Ag with infrared stealth properties. Tested by Fourier transform infrared spectrometer, it can be seen that ( image 3 ), Leather / FeO X For 8-14 μm (wavenumber 1250-714 cm -1 ) The infrared wave in the band has strong reflection, and the reflectivity is higher than 80%. It can be seen that Leather / Cu@Ag can reduce heat absorption and reduce its infrared radiation intensity by reflecting most of the thermal infrared rays. Pla...

Embodiment 3

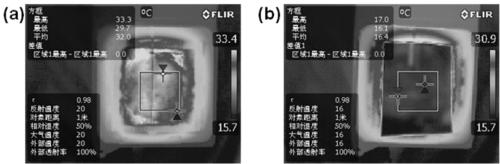

[0051] Take cowhide leather with an area of 20×20 cm, apply 4 g (theoretical spraying amount is 10 mg / cm 2 ) bismuth oxide Bi 2 o 3 The powder was dispersed in 300 mL of acetone to configure solution A; a polyurethane adhesive with a solid content of 30% (total solid content of PU and Bi 2 o 3 Mix the powder mass ratio of 0.6:1) with 150 mL of acetone to prepare solution B; after mixing solution A and solution B evenly, spray it on the surface of the taken cowhide leather at room temperature, and dry it to obtain infrared stealth. Leather Leather / Bi 2 o 3 . Will Leather / Bi 2 o 3 Placed at 32 oC on the heat source (heating plate) ( Figure 5 a), Observation of Leather / Bi by infrared thermal imager 2 o 3 The thermal radiation temperature, such as Figure 5 As shown in b, Leather / Bi 2 o 3 The temperature is 16.1 o C, close to ambient temperature, therefore, Leather / Bi 2 o 3 It can completely shield the infrared radiation intensity of the heat source, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflection loss value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com