SrZrO3 preparation method and SrZrO3 ceramic

A powder and billet technology, which is applied in the field of ceramic preparation, can solve the problems of infrared emissivity, thermal conductivity, expansion coefficient, high temperature resistance and insufficient performance to meet the needs of use, and achieve good chemical stability, low emissivity, and high thermal expansion. The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Using SrCO 3 and ZrO 2 Press n(SrCO 3 ): n(ZrO 2 )=1.02:0.98 molar ratio is fully mixed as a raw material. Mixed SrCO 3 and ZrO 2 The powder is pressed into a billet under a pressure of 8Mpa through a tablet press.

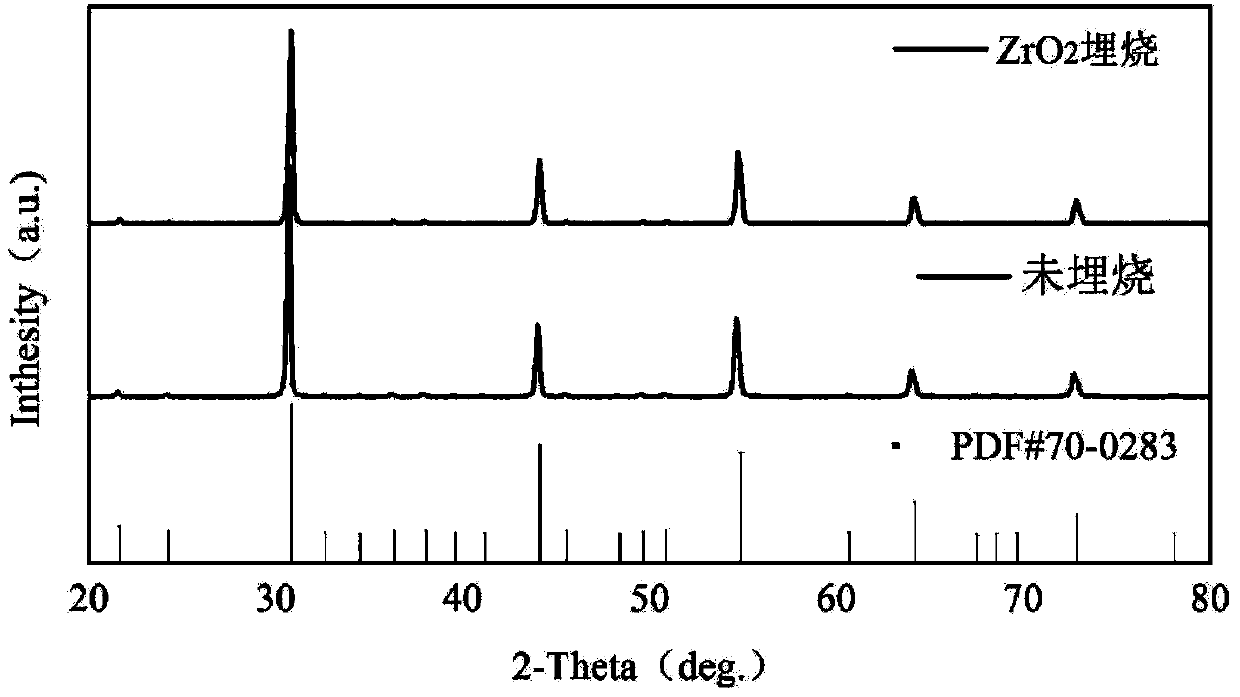

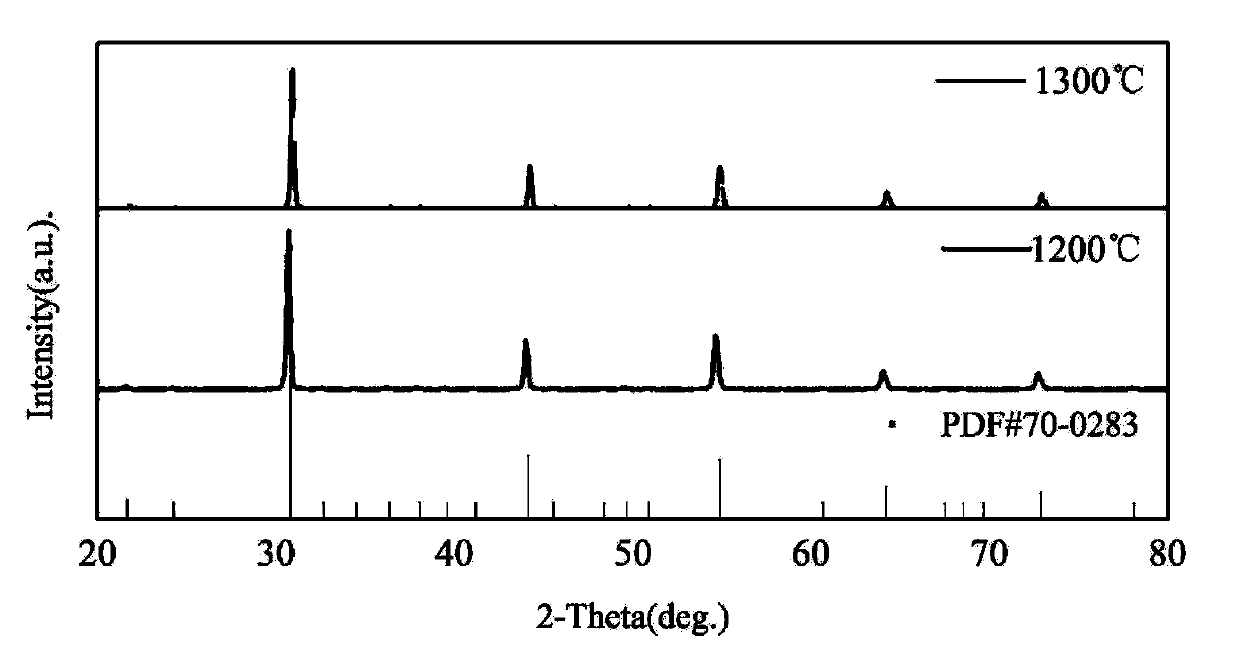

[0040] The green body is placed in a microwave sintering furnace. In order to make the green body heated evenly, ZrO 2 or Al 2 o 3 As a powder buried and fired, the sintering temperature is 1400°C, the heating rate is 10°C / min, and the holding time is 30min to obtain the final SrZrO 3 ceramic block.

Embodiment 2

[0042] Using SrCO 3 and ZrO 2 Press n(SrCO 3 ): n(ZrO 2 )=1.04:0.96 molar ratio fully mixed as raw material; mixed SrCO 3 and ZrO 2 The powder is pressed into a billet by a tablet press under a pressure of 10Mpa.

[0043] The green body is placed in a microwave sintering furnace. In order to make the green body heated evenly, ZrO 2 or Al 2 o 3 The powder is buried and fired, the sintering temperature is 1500°C, the heating rate is 15°C / min, and the holding time is 1h to obtain the final SrZrO 3 ceramic block.

Embodiment 3

[0045] Using SrCO 3 and ZrO 2 Press n(SrCO 3 ): n(ZrO 2 )=1.02:0.98 molar ratio is fully mixed as a raw material; the mixed SrCO 3 and ZrO 2 The powder is placed in an isostatic pressing press with a pressure of 25Mpa to form a billet.

[0046] The green body is placed in a microwave sintering furnace, ZrO 2 or Al 2 o 3 Powder assisted burying and sintering, the sintering temperature was 1500°C, the heating rate was 15°C / min, and the holding time was 30min to obtain the final SrZrO 3 ceramic block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com