Pipe with rib and method for manufacturing pipe with rib

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

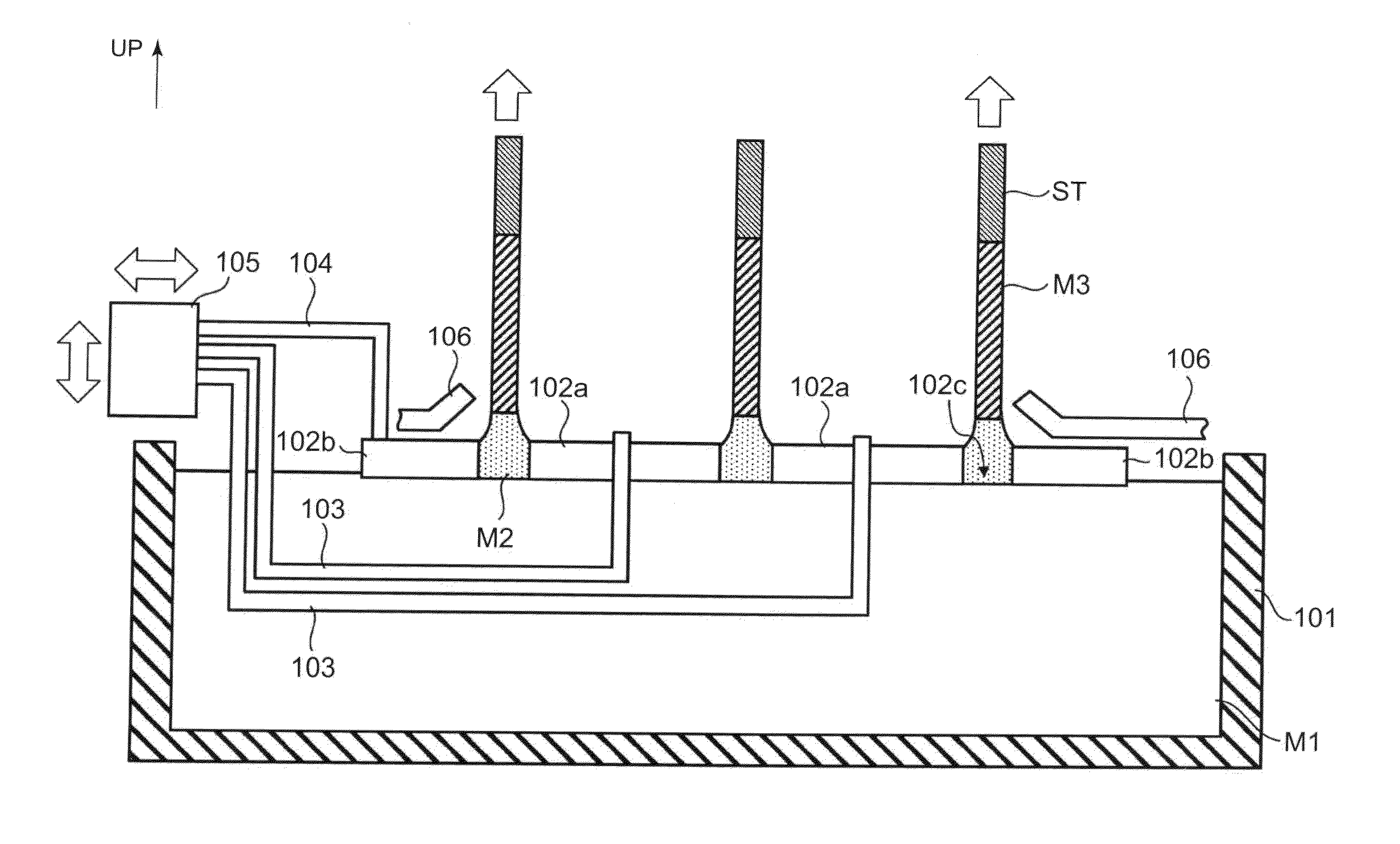

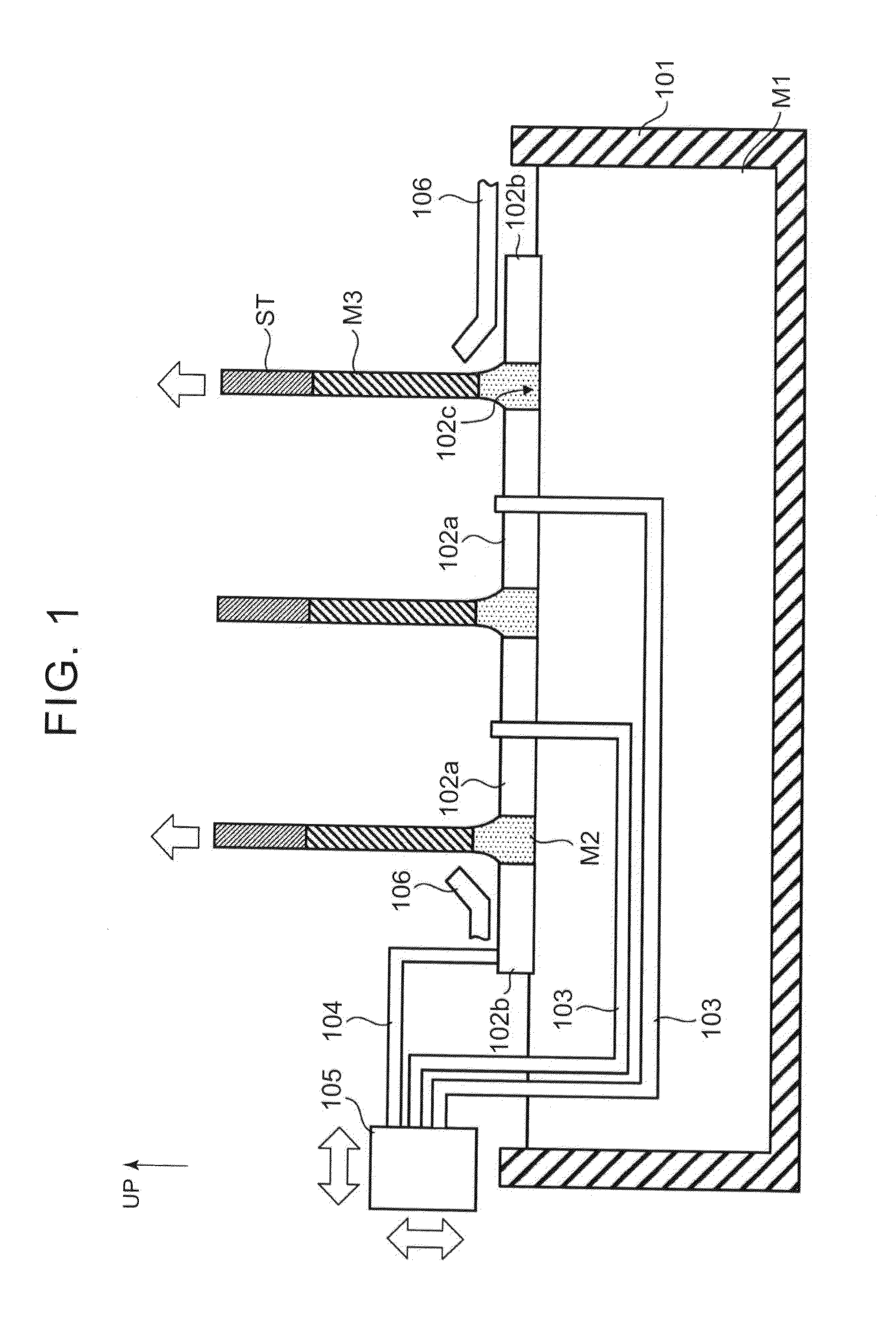

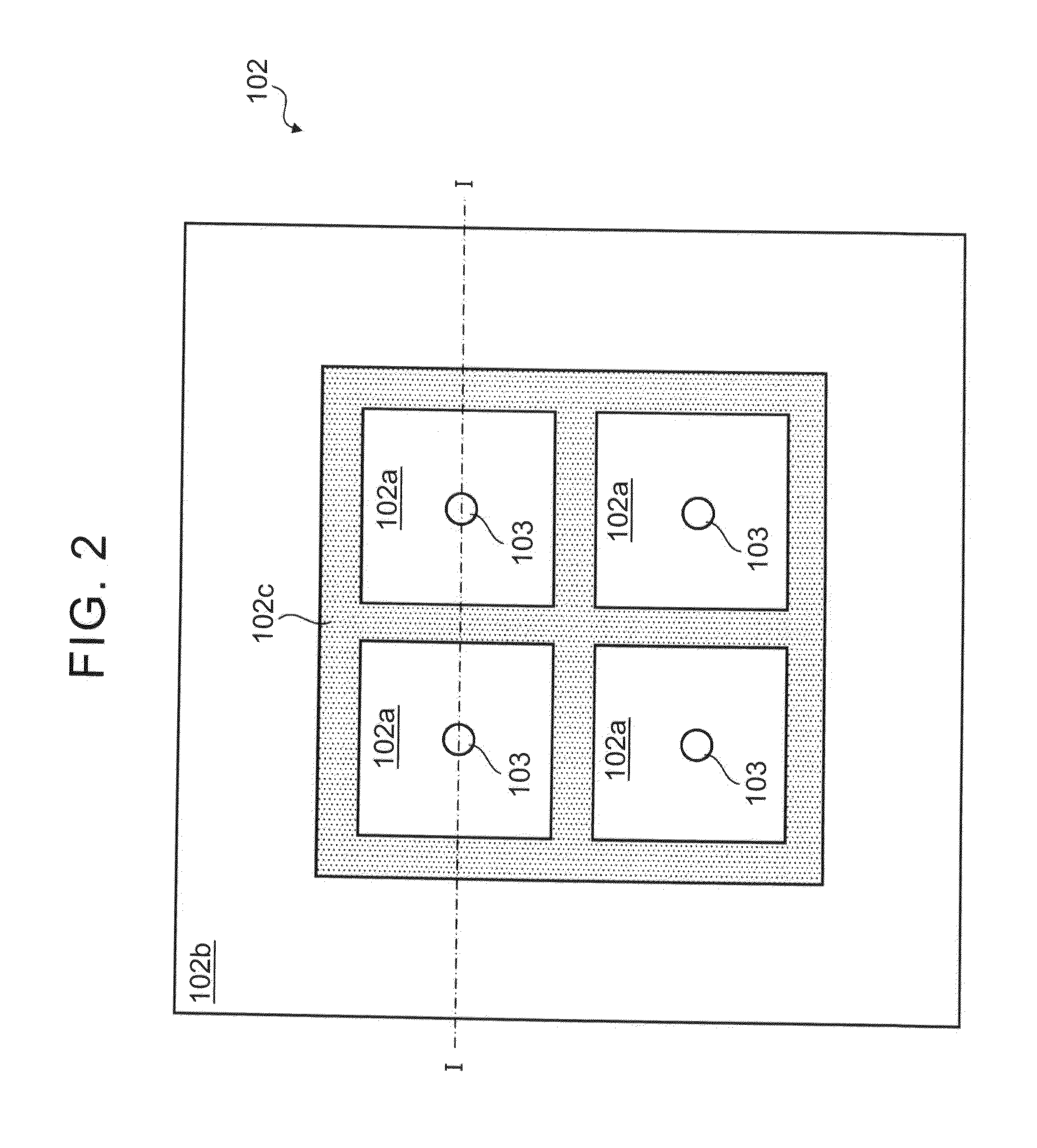

[0028]First, a free casting apparatus (an up-drawing continuous casting apparatus) according to a first embodiment will be explained with reference to FIG. 1. FIG. 1 is a sectional view of a free casting apparatus according to the first embodiment. As shown in FIG. 1, the free casting apparatus according to the first embodiment includes a molten metal holding furnace 101, inner shape defining members 102a, an outer shape defining member 102b, inner cooling gas nozzles 103, a support rod 104, an actuator 105, and outer cooling gas nozzles 106.

[0029]The molten metal holding furnace 101 holds molten metal M1 such as aluminum and an aluminum alloy, and keeps the molten metal M1 at predetermined temperature. In the example shown in FIG. 1, since the molten metal is not replenished in the molten metal holding furnace 101 during casting, a surface of the molten metal M1 (or a molten metal surface) is lowered along with a progress of casting. However, the molten metal may be replenished int...

second embodiment

[0044]A casting M3 according to a second embodiment will be explained with reference to FIG. 6A and FIG. 6B. FIG. 6A is a photograph showing external appearance of an example of the casting M3 according to the second embodiment, and FIG. 6B is an X-ray photograph of a twisted portion. The casting M3 shown in FIG. 6A includes a twisted portion 31. The casting M3 is also made of an aluminum alloy A6063 and has a section having a cross inside a square shape with a thickness of 1.5 to 2.5 mm (a gap in the molten metal passage portion 102c is 3.0 mm). FIG. 6B is an X-ray photograph of the twisted portion 31 seen from above. The twisted portion was photographed by using a digital X-ray sensor NX-06 and a portable X-ray photographic apparatus PX-20HF, made by RF Co., Ltd., under conditions with tube voltage of 74 kVp and tube current time of 25 mAs. As shown in FIG. 6B, in the twisted portion 31, a pipe portion M31 and a rib portion M32 are both twisted about a longitudinal direction of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com