Fill system and method including visual indicator device for empty condition

a filling system and visual indicator technology, applied in the field of adhesive pellet filling system and method, can solve the problems of slow container drop, inability to fill hands, and difficulty in gauging how much material is left in the supply container, so as to minimize the additional resistance to flow and minimize the amount of space required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

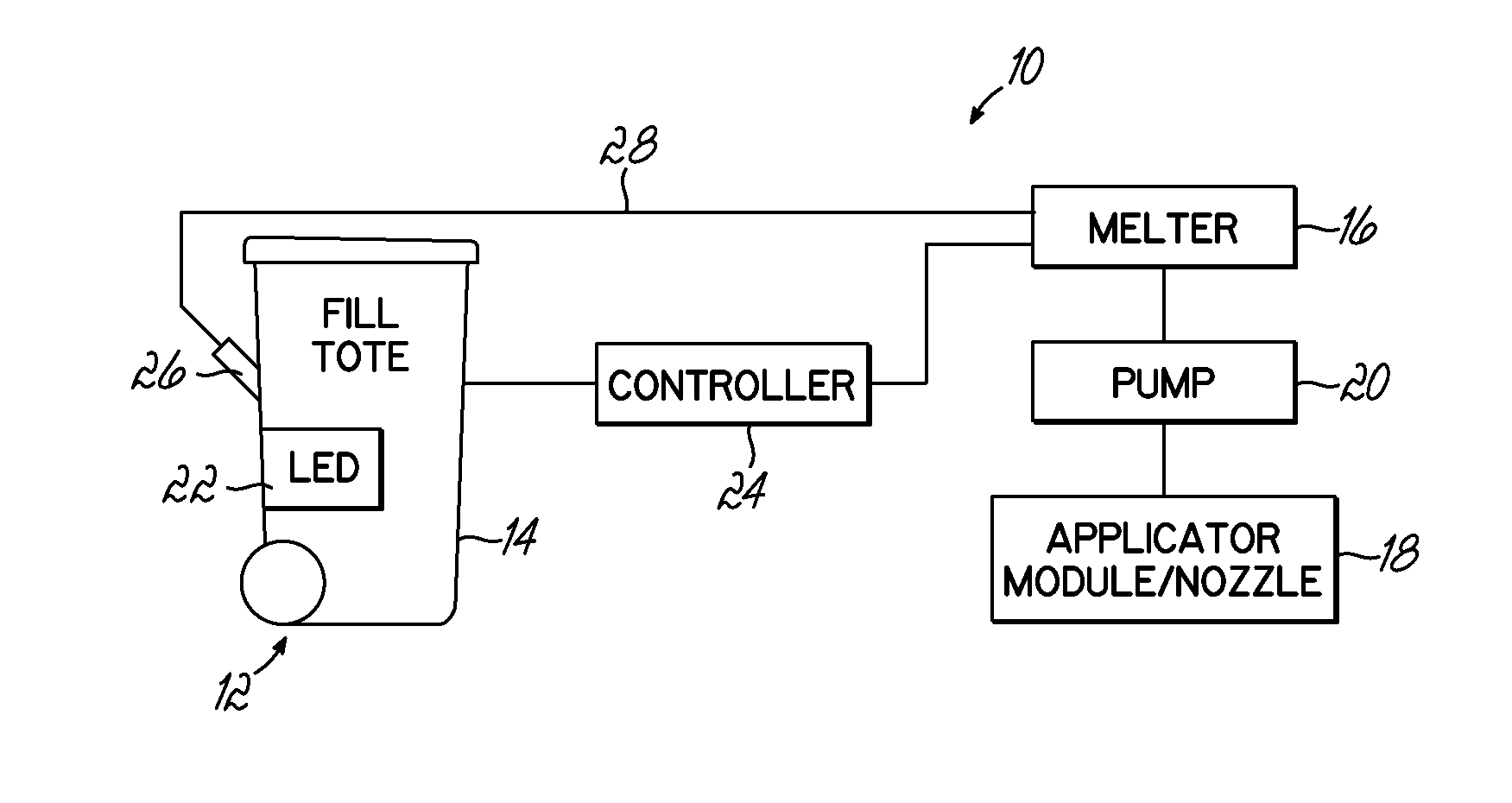

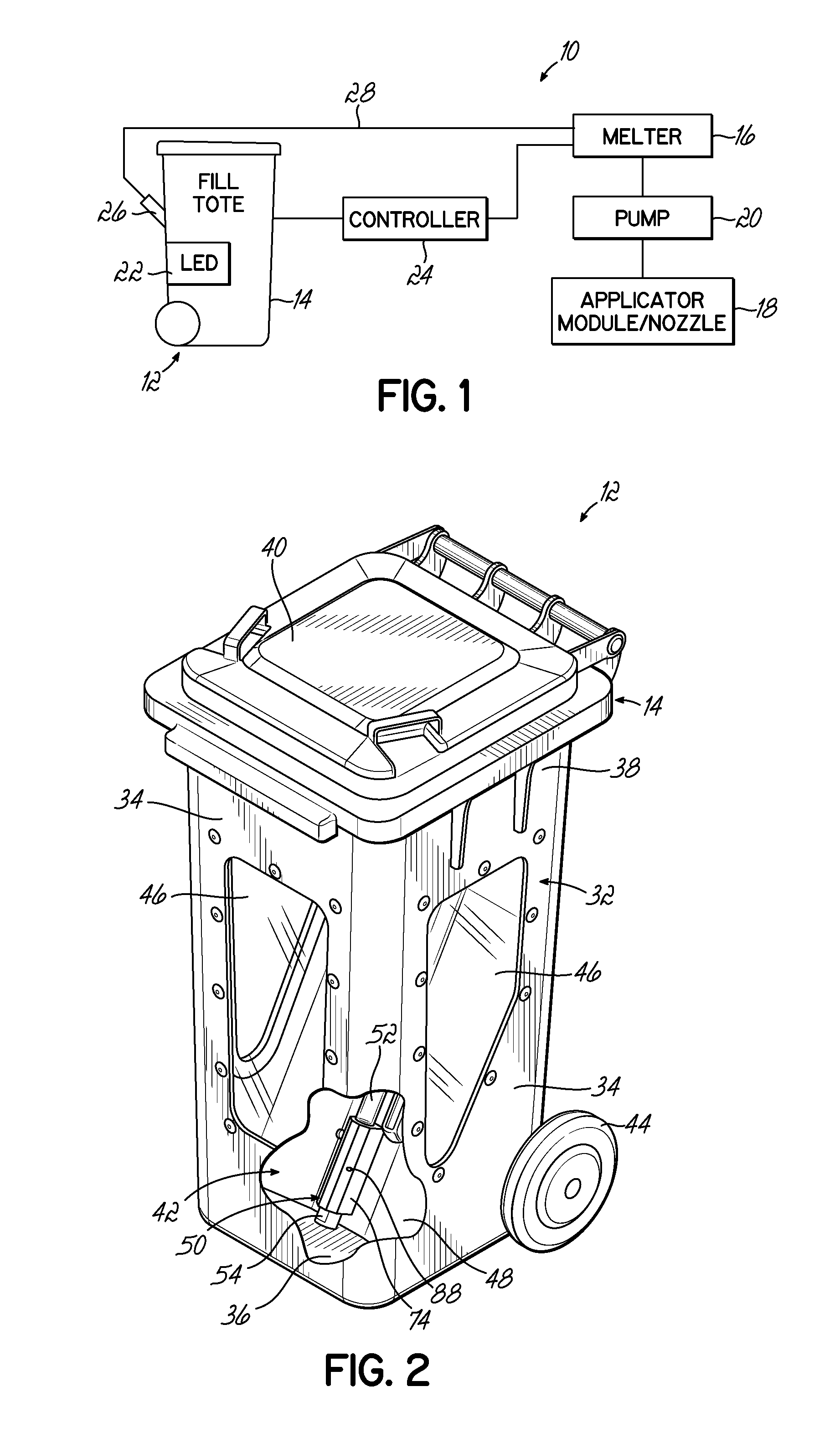

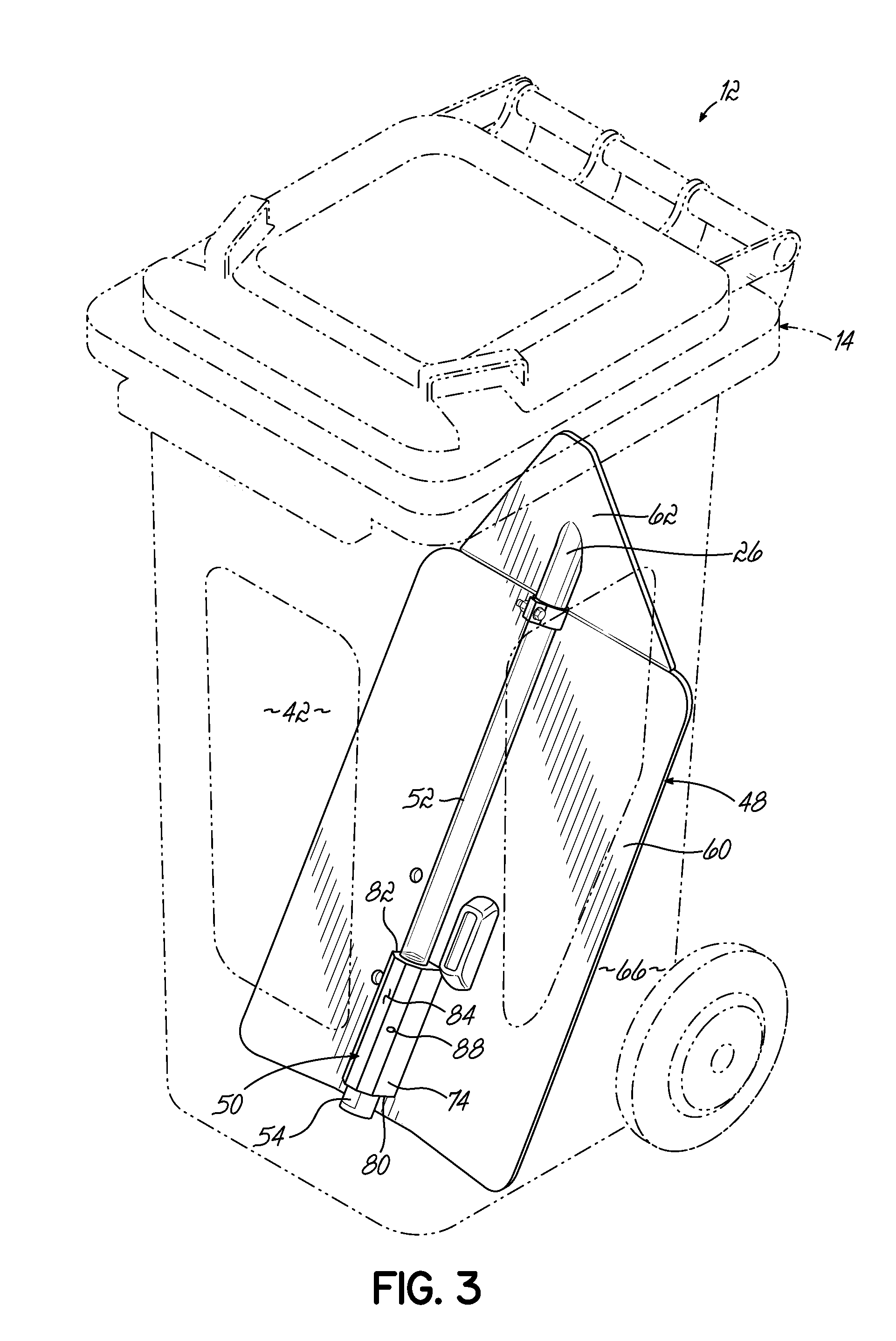

[0026]Referring to FIG. 1, an adhesive dispensing system 10 in accordance with one embodiment of the invention includes a fill system 12 that is configured to provide a visual indication when the particulate adhesive within a supply container 14 is approaching an empty condition. More specifically, the fill system 12 is used to provide adhesive pellets to a melter 16 of the adhesive dispensing system 10, and the melter 16 feeds liquefied molten adhesive to an applicator module or nozzle 18 using a liquid pump 20. In this regard, the fill system 12 is operated to continually replenish the supply of adhesive within the melter 16 as the pump 18 removes molten adhesive for dispensing at the applicator module or nozzle 18. The adhesive material may define any form or shape that is convenient for delivering by the fill system 12 and for melting by the adhesive melter 16; however, “pellets” have been chosen for illustrative purposes in the illustrated embodiment. It will be understood that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com