Structure and method for adjusting balance of turbocharging device incorporating electric motor

a turbocharging device and electric motor technology, applied in the direction of positive displacement liquid engines, pumps, machines/engines, etc., can solve the problems of fine adjustment, affecting the performance of the motor that utilizes the magnet, and the adjustment of the rotational balance on a conventional adjustment part, so as to prevent performance deterioration and achieve sufficient motor driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

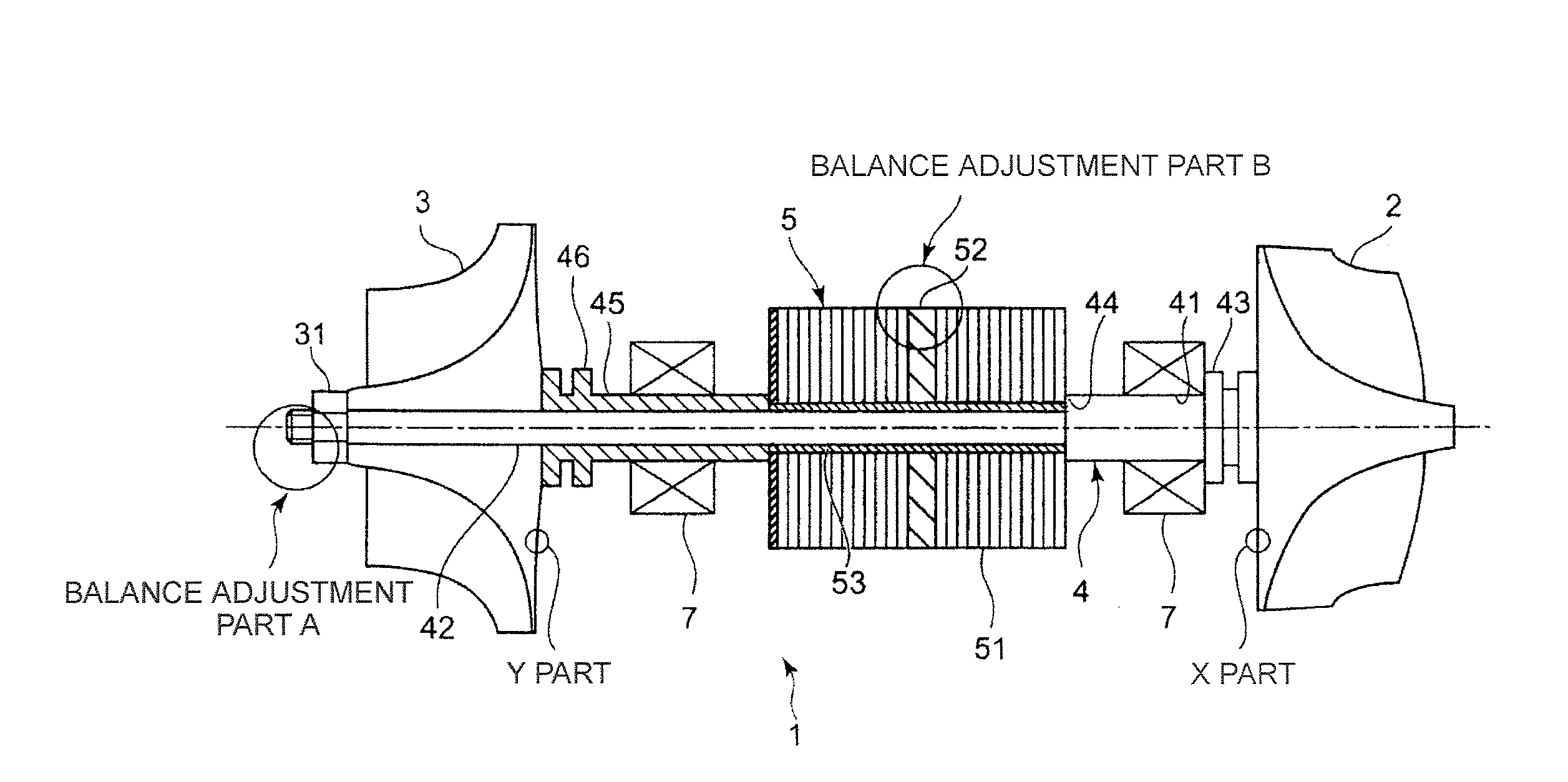

[0049]A turbine rotor according to a first embodiment of the present invention will be described with reference to FIG. 1.

[0050]A turbine rotor 1 includes a shaft 4, a turbine wheel 2 disposed on one end of the shaft 4, a compressor impeller 3 disposed on the other end thereof, two bearings 7 disposed between the turbine wheel 2 and the compressor impeller 3 at intervals, and a rotor core 5 that serves as an electric rotor, and is disposed between the two bearings 7, and the rotor core 5 is mounted on the shaft 4 via a sleeve 53.

[0051]The present invention is applicable to both of a case where the respective bearings 7 are arranged on both outer ends of the rotor core 5 as described above, and a case where the two (pair of) bearings 7 are arranged between the turbine wheel 2 and the rotor core 5 at intervals.

[0052]The shaft 4 is a solid shaft, has a stepped part 44 narrowed from an intermediate part, and is a rotary shaft having a thick portion 41 on one end and a narrow portion 42 ...

second embodiment

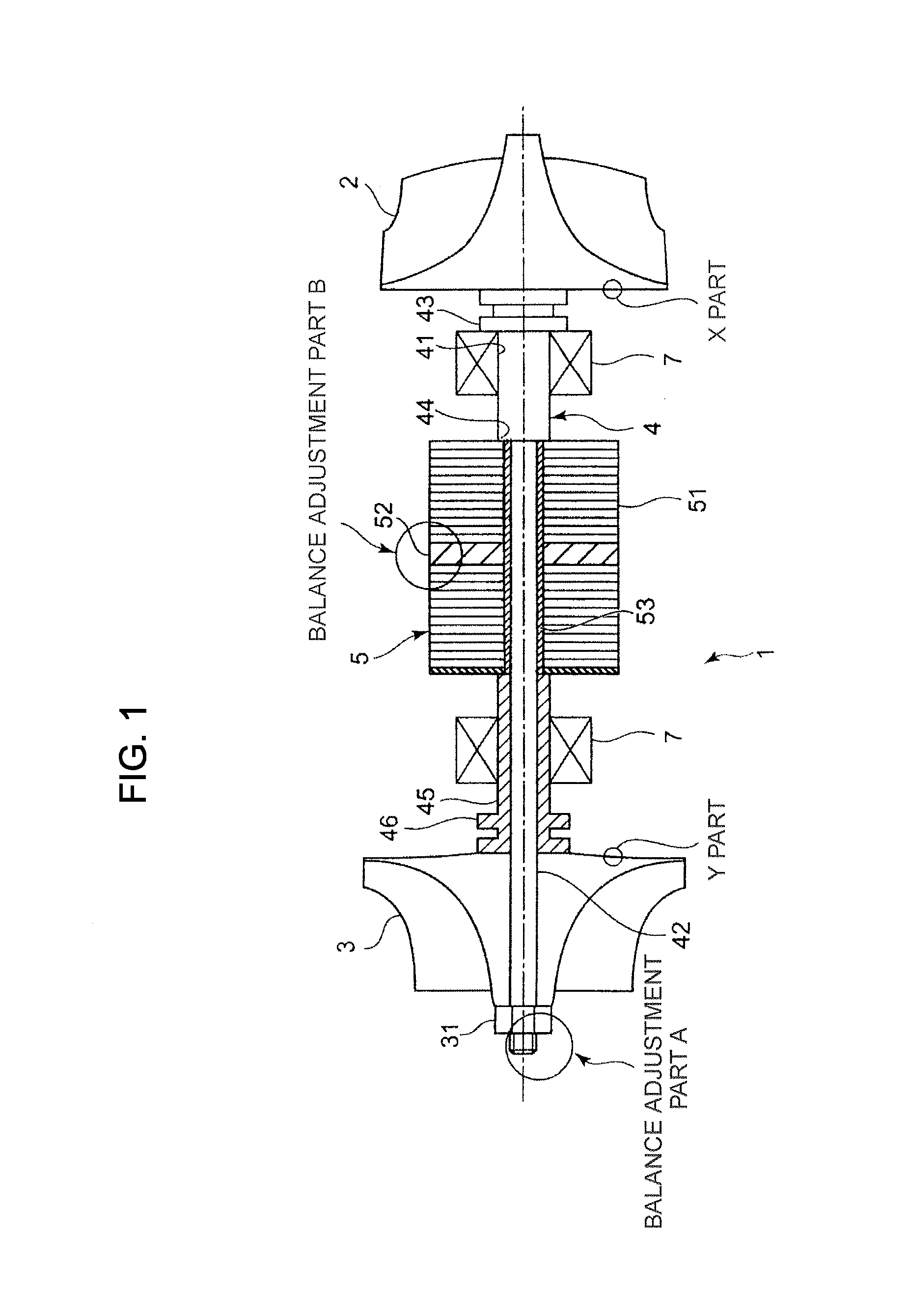

[0086]In this second embodiment, components that are identical with those of the first embodiment are denoted by the same reference numerals, and description thereof will be omitted.

[0087]As shown in FIG. 2, a rotor core 8 is configured such that a plurality of electromagnetic steel plates 51 are disposed on a sleeve 81 fitted onto a narrow portion 42 of a shaft 4.

[0088]The sleeve 81 is formed with a flange part 82 radially from an open edge on one end side of the sleeve 81.

[0089]On the outer peripheral part of the sleeve 81, the electromagnetic steel plates 51 are fitted onto the sleeve 81 so as to be laminated in the thrust direction of the sleeve 81.

[0090]On the other end side of the sleeve 81, a pressing ring 83 is fitted onto the outer peripheral part of the sleeve 81 to be fixed in caulking to the sleeve 81 in a state of pressing the electromagnetic steel plates 51 in the thrust direction.

[0091]Additionally, a center target 55 having an outer diameter substantially identical w...

third embodiment

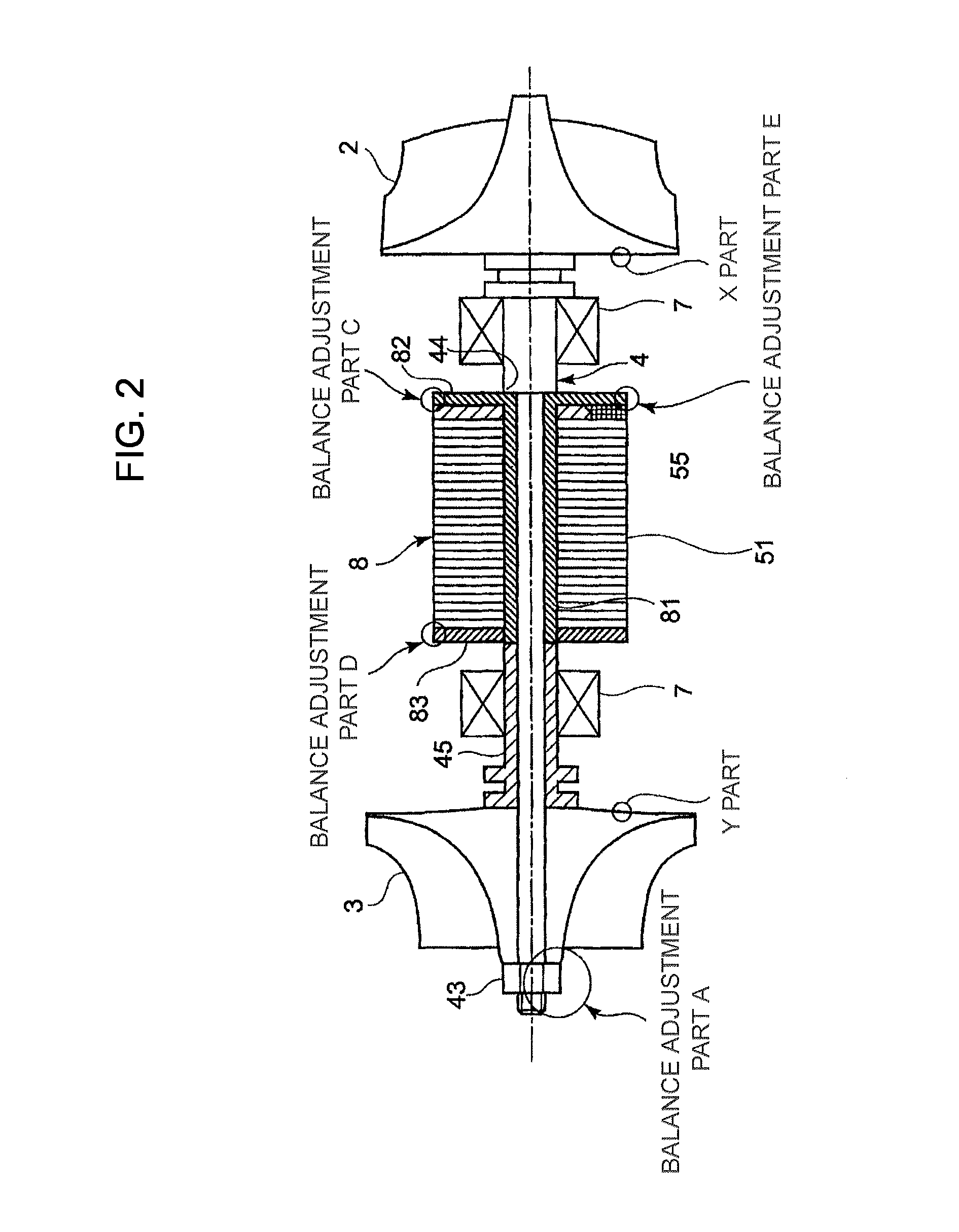

[0097]In this third embodiment, components that are identical with those of the first and second embodiments are denoted by the same reference numerals, and description thereof will be omitted.

[0098]As shown in FIG. 3, a rotor core 9 is configured such that a plurality of electromagnetic steel plates 51 and a center ring 52 being a rotational balance adjusting member are disposed on a sleeve 81 fitted onto a narrow portion 42 of a shaft 4.

[0099]The sleeve 81 is formed with a flange part 82 radially from an open edge on the one end side of the sleeve 81.

[0100]On the outer peripheral part of the sleeve 81, the electromagnetic steel plates 51 are fitted onto the sleeve 81 so as to be laminated in the thrust direction of the sleeve 81. The center ring 52 being a rotational balance adjusting member is disposed on the intermediate part of the laminated electromagnetic steel plates 51 in the thrust direction of the sleeve 81, particularly on the central part. On the other end side of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com