Light-weight strengthened, low-emittance vacuum-insulated glass (VIG) windows

a vacuum-insulated glass and low-emittance technology, applied in glass making apparatus, transportation and packaging, manufacturing tools, etc., can solve the problems of low-e coating ablation, relative movement of glass panes and spacers, and unsightly windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

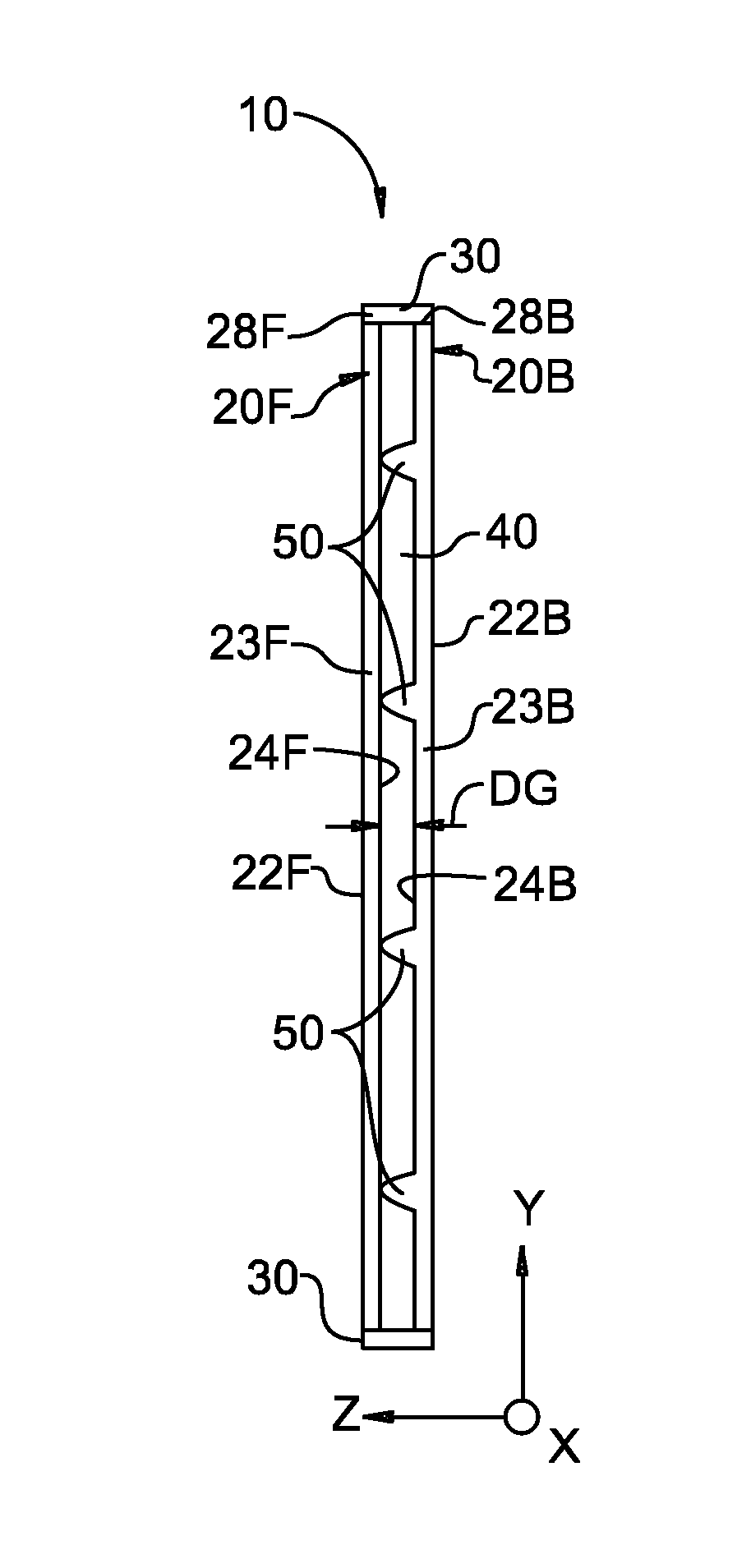

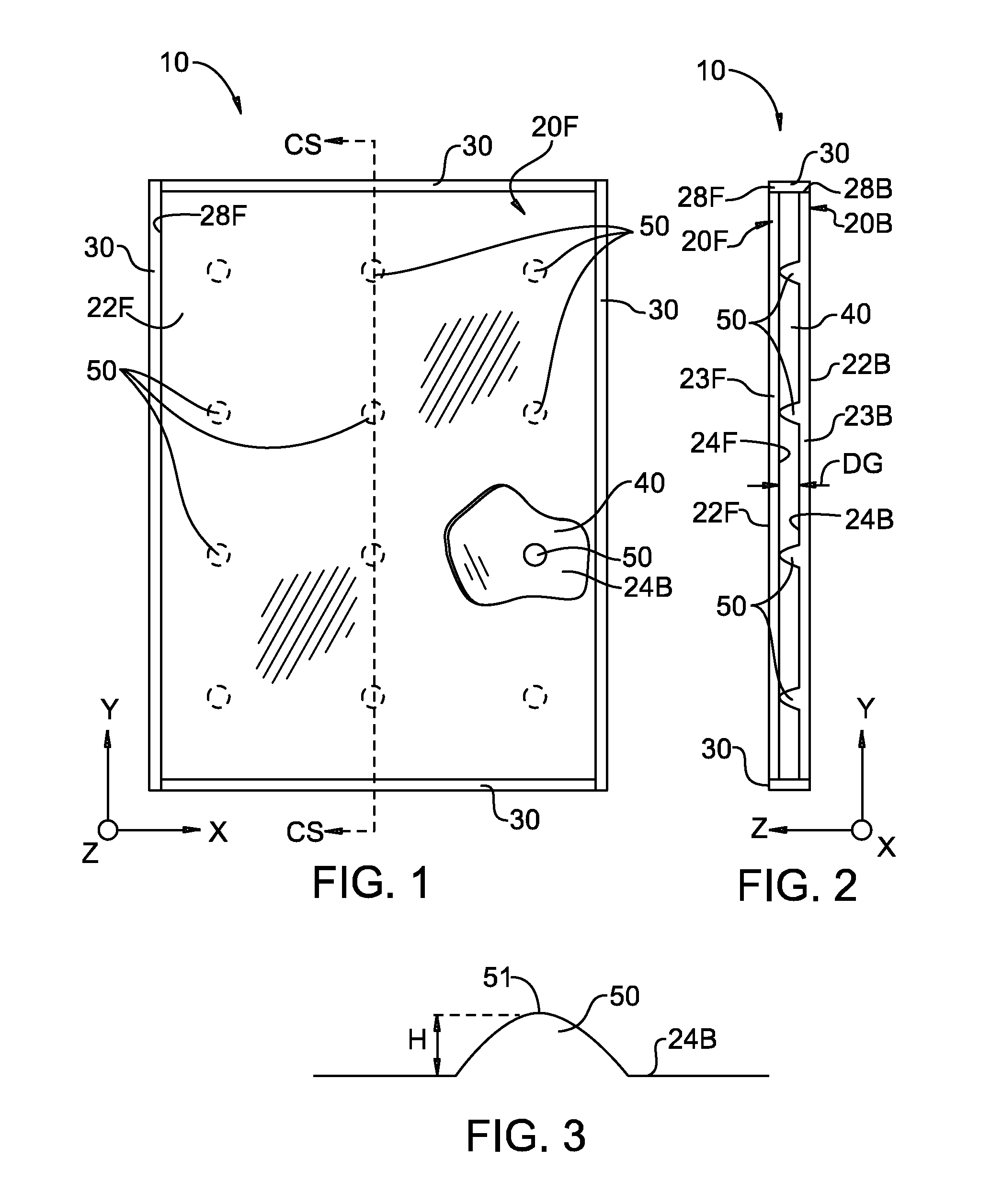

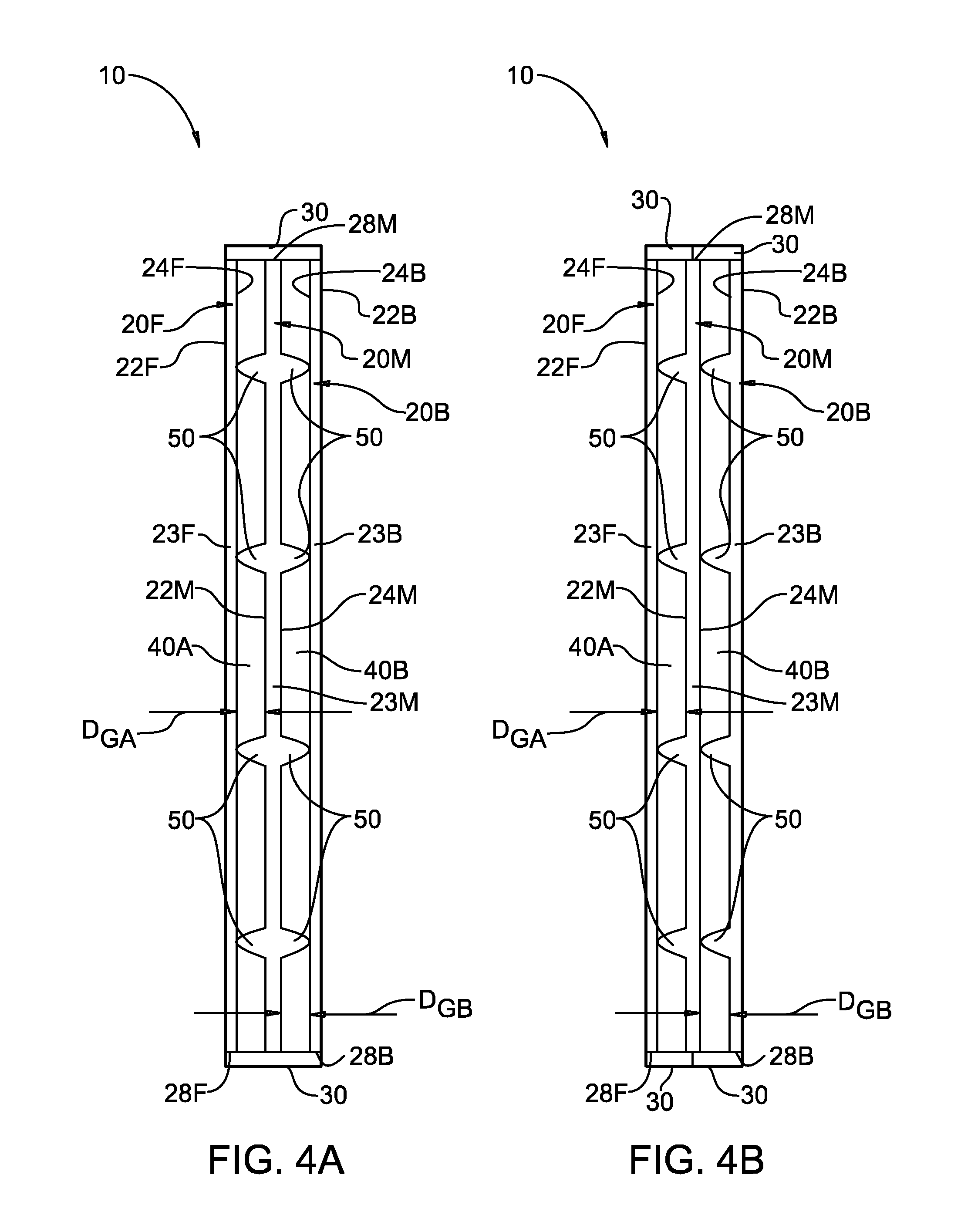

[0029]A vacuum-insulated glass (VIG) window comprises a first glass pane, a second glass pane spaced apart from and disposed substantially parallel to the first glass pane at a first distance, a plurality of glass-bump spacers integrally formed in a first surface of the first glass pane, and a first optical coating formed over both the glass-bump spacers and the first surface in which the first glass-bump spacers are formed, wherein at least one of the first glass pane and the second glass pane comprises a chemically-strengthened glass material, and the plurality of coated glass-bump spacers contact the second glass pane so as to maintain said spaced apart first distance. Two or more glass panes may be incorporated into a VIG window that comprises an evacuated region between adjacent glass panes. Aspects of forming glass-bump spacers, chemically-strengthened glass panes and optical coatings such as low-emittance (low-E) coatings are described below.

[0030]As disclosed herein, glass-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com