Aramid fiber cord and method for manufacturing the same

a technology of aramid fiber and tenacity, which is applied in the field of aramid fiber cord, can solve the problems of low heat resistance and adhesion strength of rayon fiber with respect to rubber, inconvenient use of tires, and inability to meet the needs of tires,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

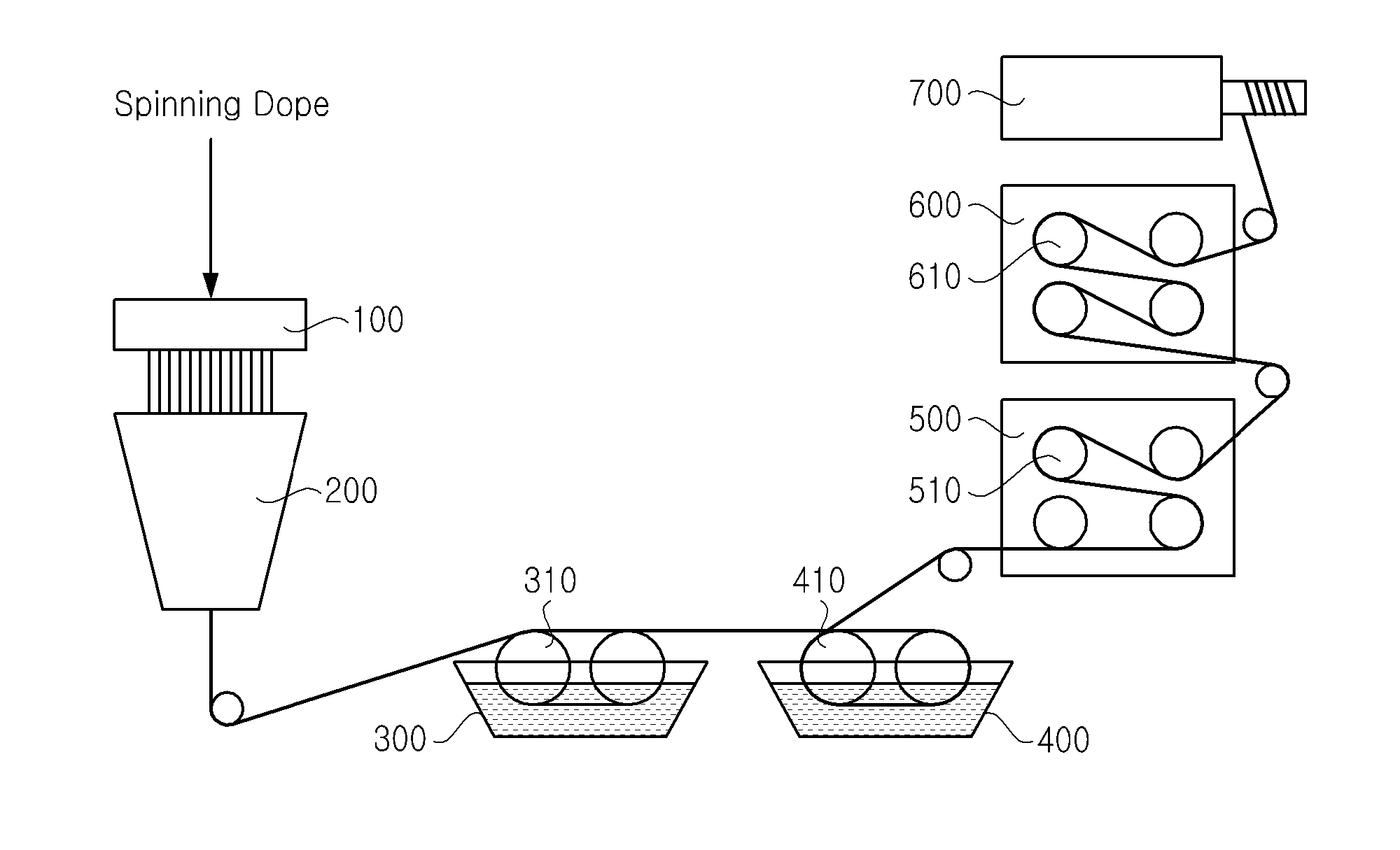

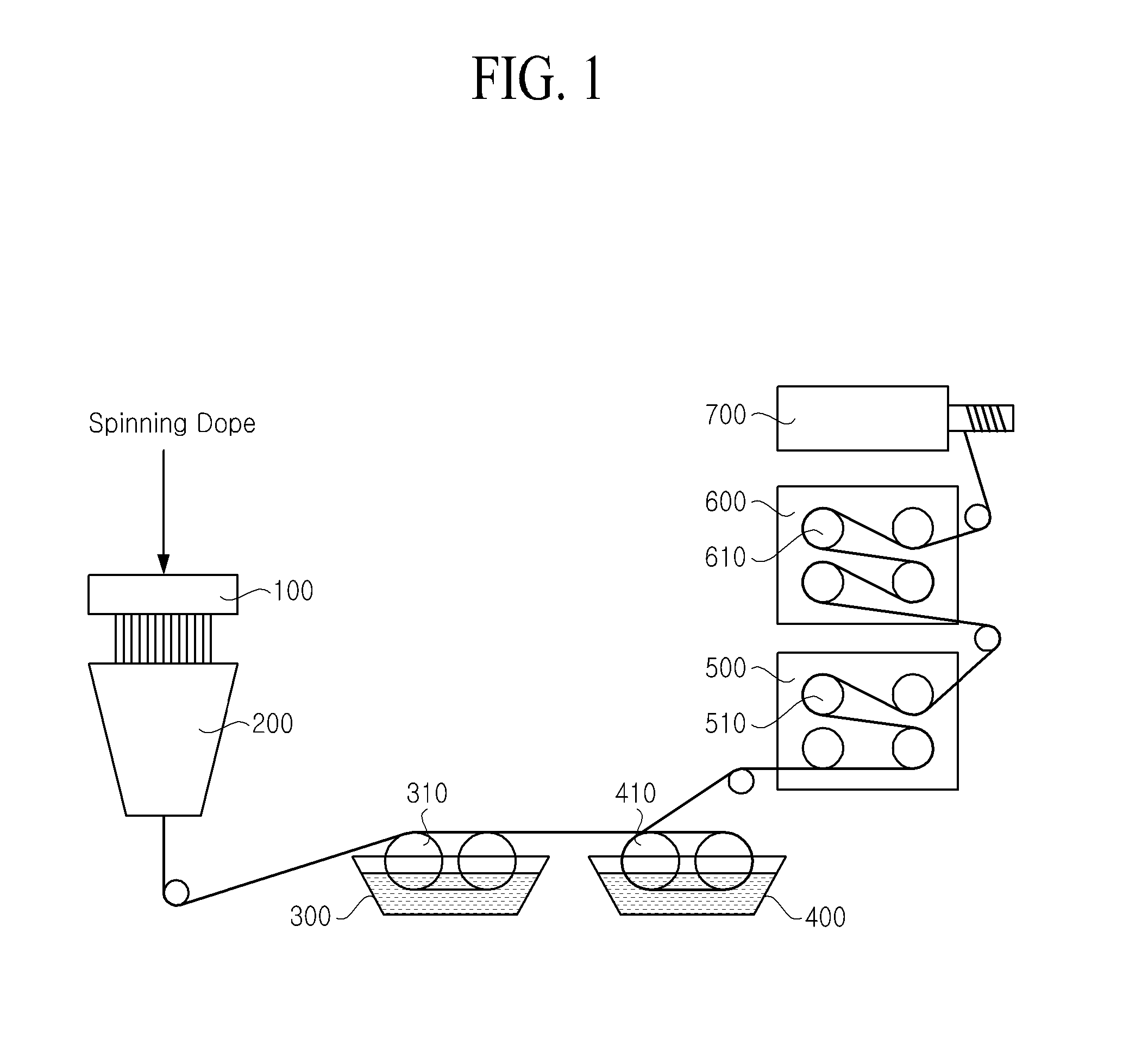

[0053]A spinning dope was prepared by dissolving poly(paraphenylene terephthalamide) (PPD-T) having inherent viscosity (I.V.) of 5.5 in a 100% concentrated sulfuric acid solvent. A multifilament was formed by spinning the spinning dope through a spinneret, and then allowing the dope to pass through an air gap of 7 mm and a coagulation bath containing 13% sulfuric acid aqueous solution sequentially to coagulate it.

[0054]To remove the sulfuric acid remaining in the aramid multifilament, the first washing of the multifilament was performed in the first washing bath containing 0.5% aqueous caustic solution, and then the second washing was performed in the second washing bath containing 0.05% aqueous caustic solution.

[0055]Subsequently, a drying process was carried out to remove the moisture remaining in the aramid multifilament and the dried aramid multifilament was heat-treated so that a final aramid multifilament can be obtained.

[0056]The aramid multifilament was primarily twisted in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tenacity retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com