Method and system for utilizing heat in a plant or animal growing device, and greenhouse

a technology for growing devices and greenhouses, which is applied in the field of methods and systems for utilizing heat in plants or animals growing devices, and greenhouses, can solve the problems that the devices described above do not use the energy of the heat source in an optimal manner, and achieve the effects of less heat being thrown, and reducing the amount of hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

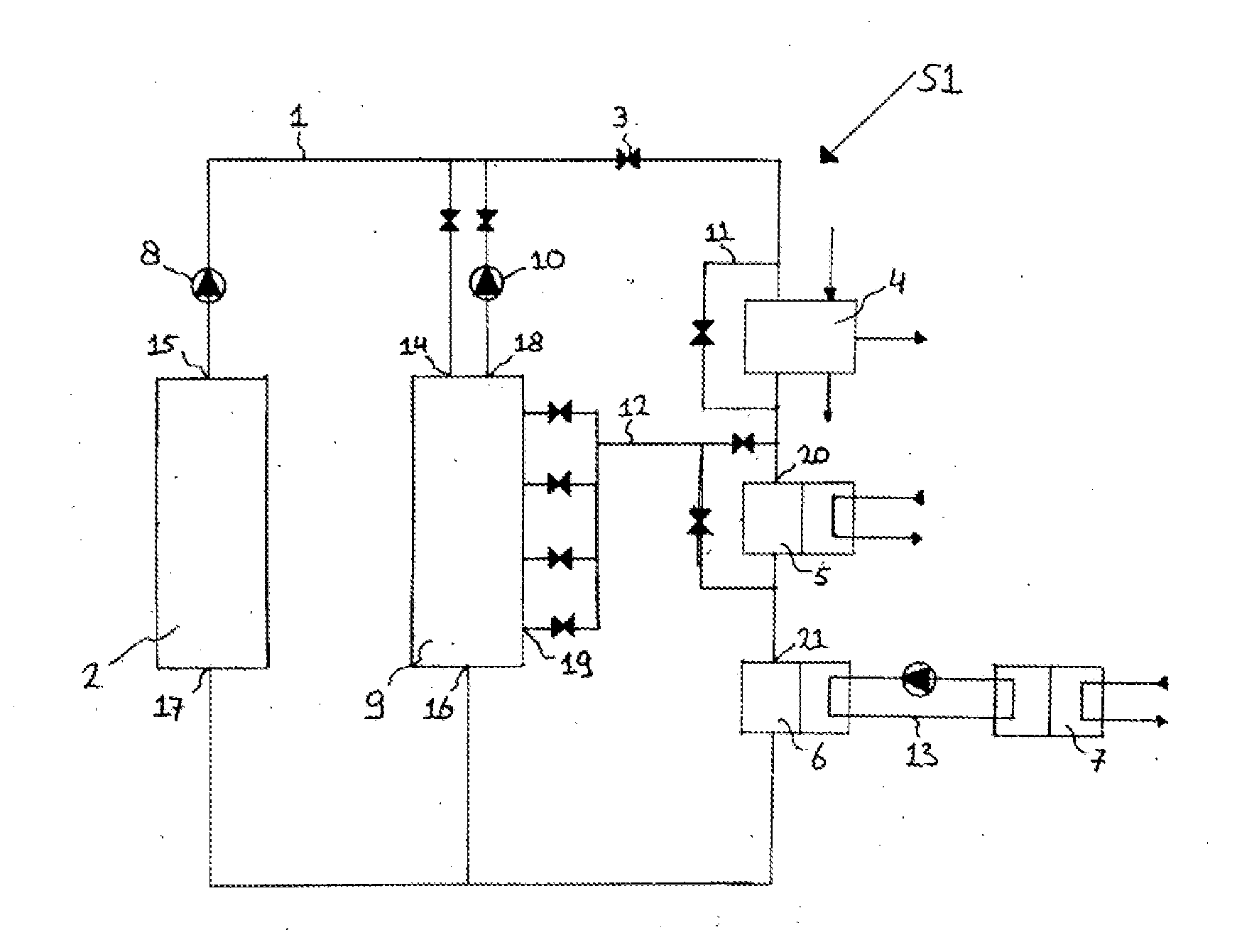

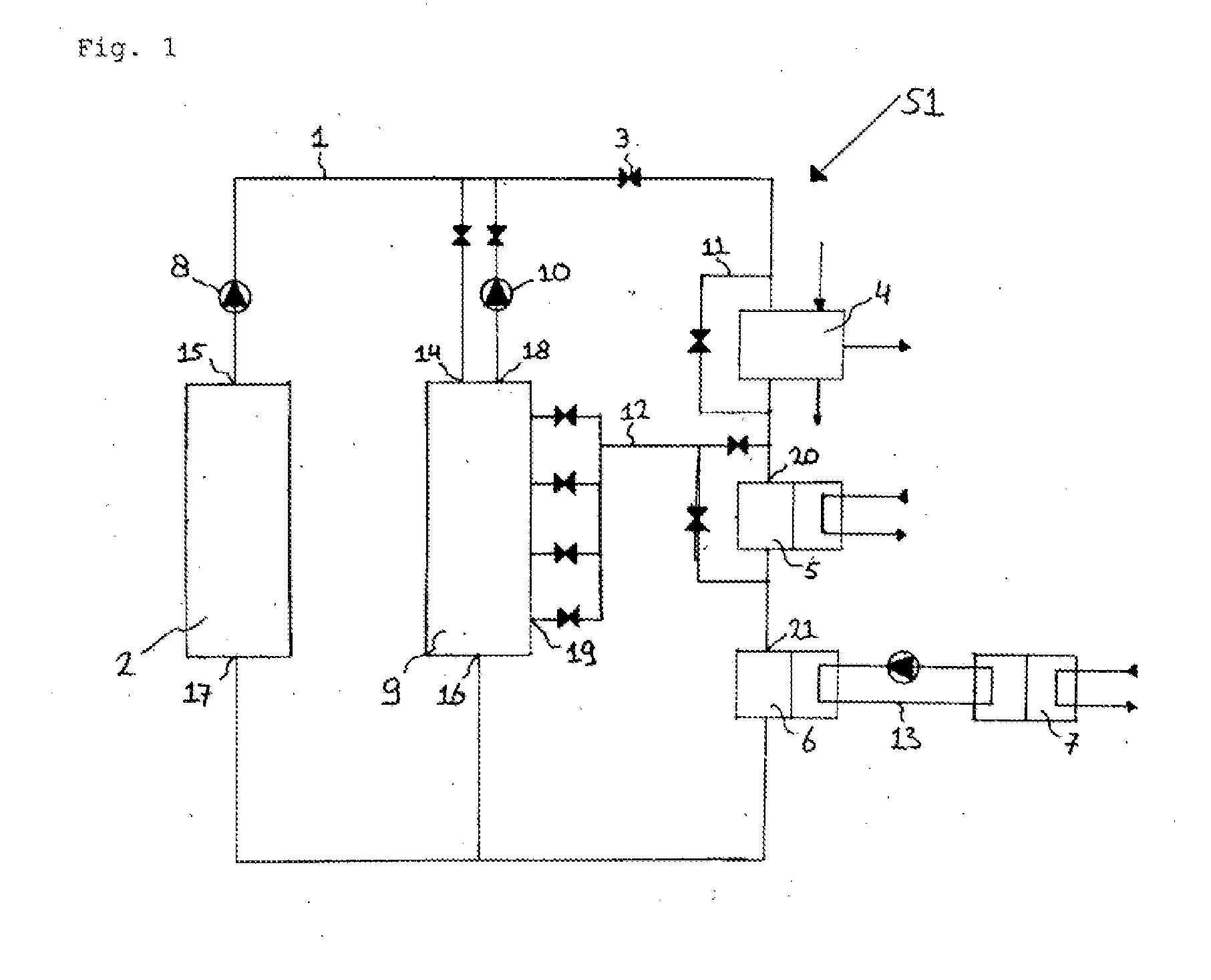

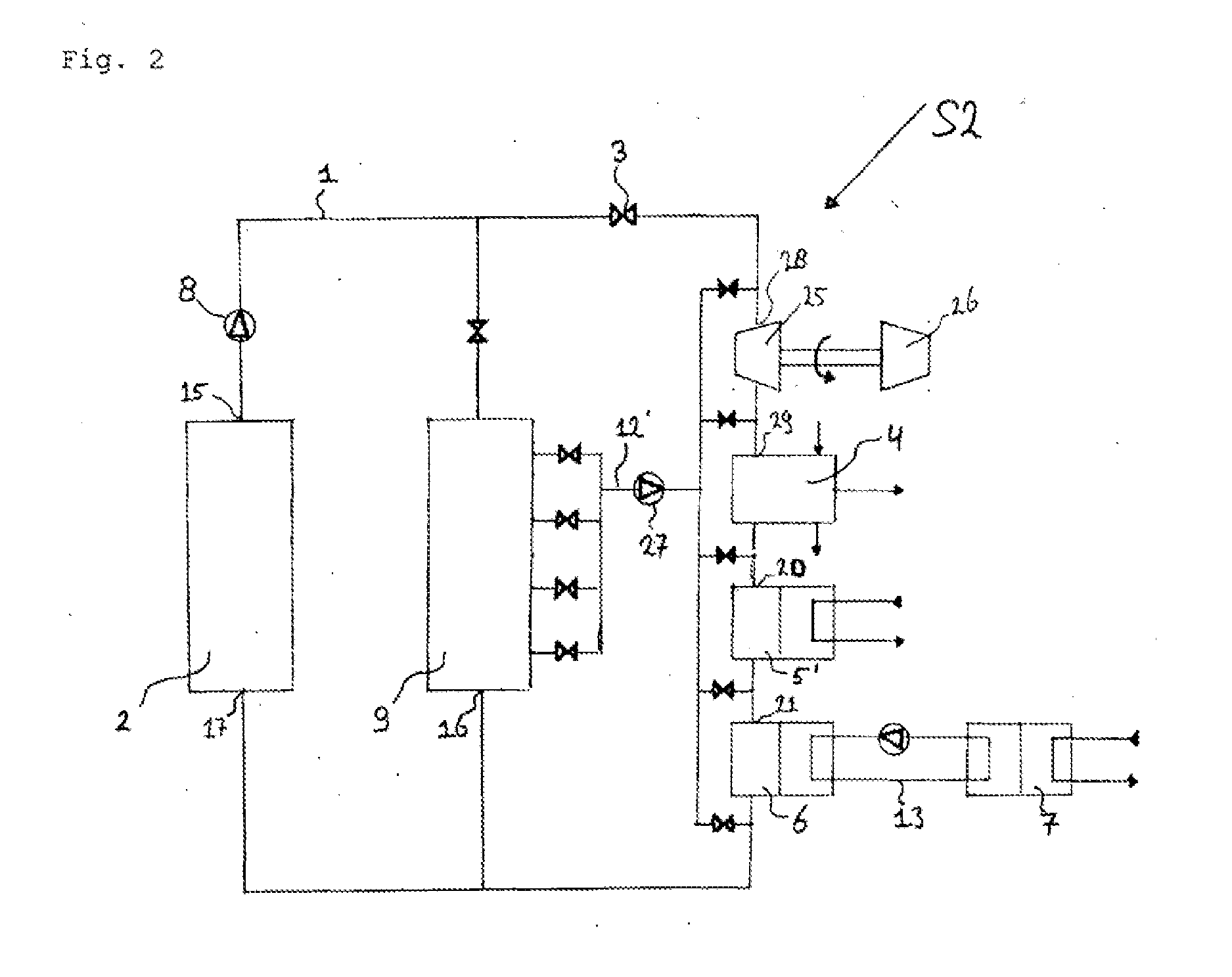

[0020]An exemplary embodiment of a system S1, S2 which is part of a greenhouse for growing plants of the present invention is described with reference to FIGS. 1 and 2.

[0021]The system S1 includes tubes, or piping, 1 represented by lines. The system S1 also contains a solar collector 2 that makes use of optical mirrors (not shown) to concentrate incident solar rays on a fluid line, and as such, to heat the fluid in the fluid line of the solar collector. The solar collector 2 is part of a fluid loop which includes the tubes 1, valves 3, a thermal desalination unit 4, a salt production unit 5, a heat exchanger 6 for a greenhouse air space heating 7 and an electrical pump 8. Arranged parallel to the line with the solar collector 2 and the pump 8 is a line with a heat buffer tank 9 and a pump 10. Line 11 is a bypass line for the thermal desalination unit 4. Line 12, between the buffer tank 9 and the salt production unit 5, connect the buffer tank 9 with the salt production unit 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com