Dispensing container

a container and chlorine dioxide technology, applied in the field of separate compositions, can solve the problems of affecting the quality reducing the shelf life of chlorine dioxide mouth rinses, so as to achieve the effect of reducing the risk of cancer, and sacrificing any palatability or efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

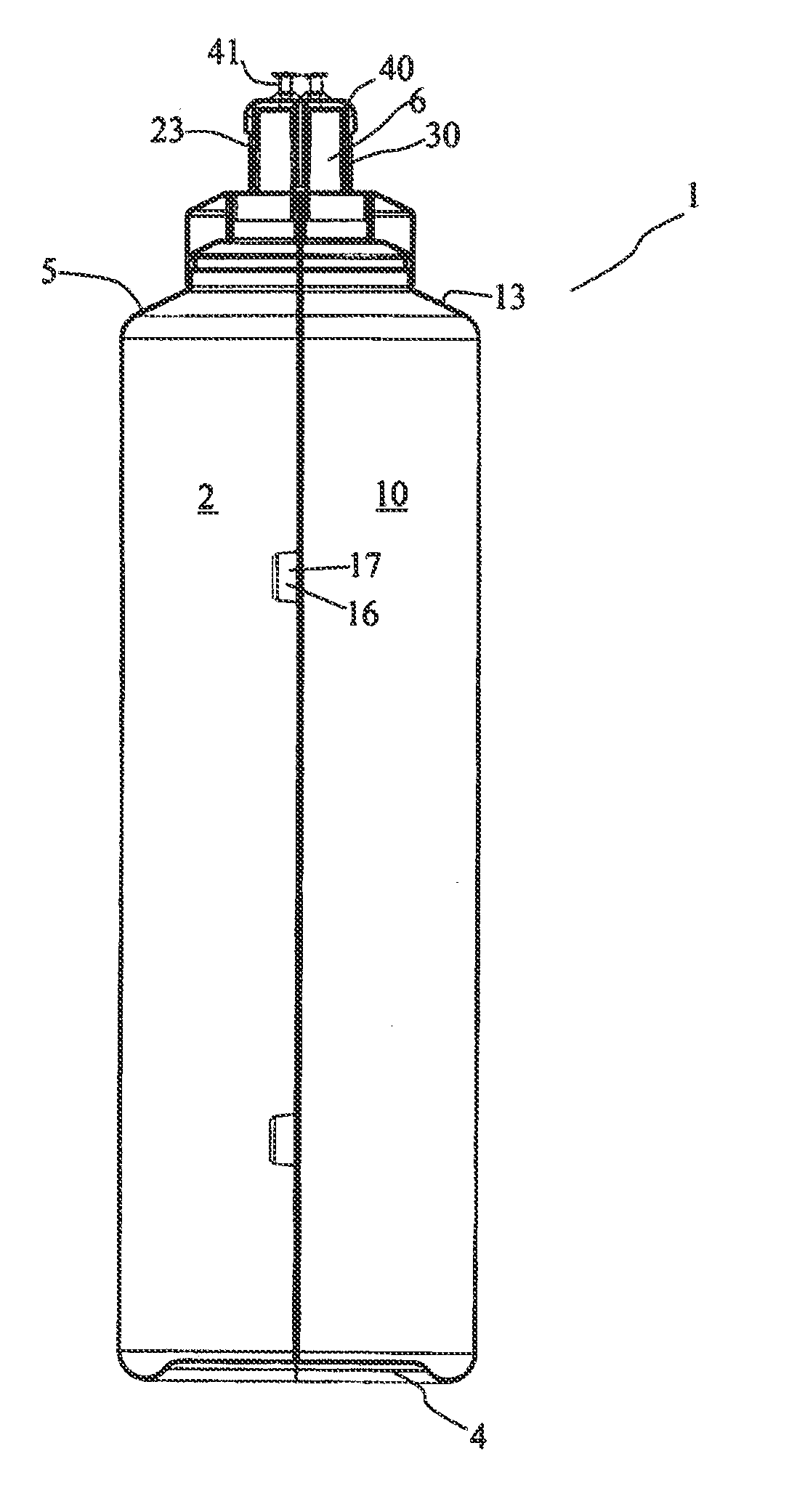

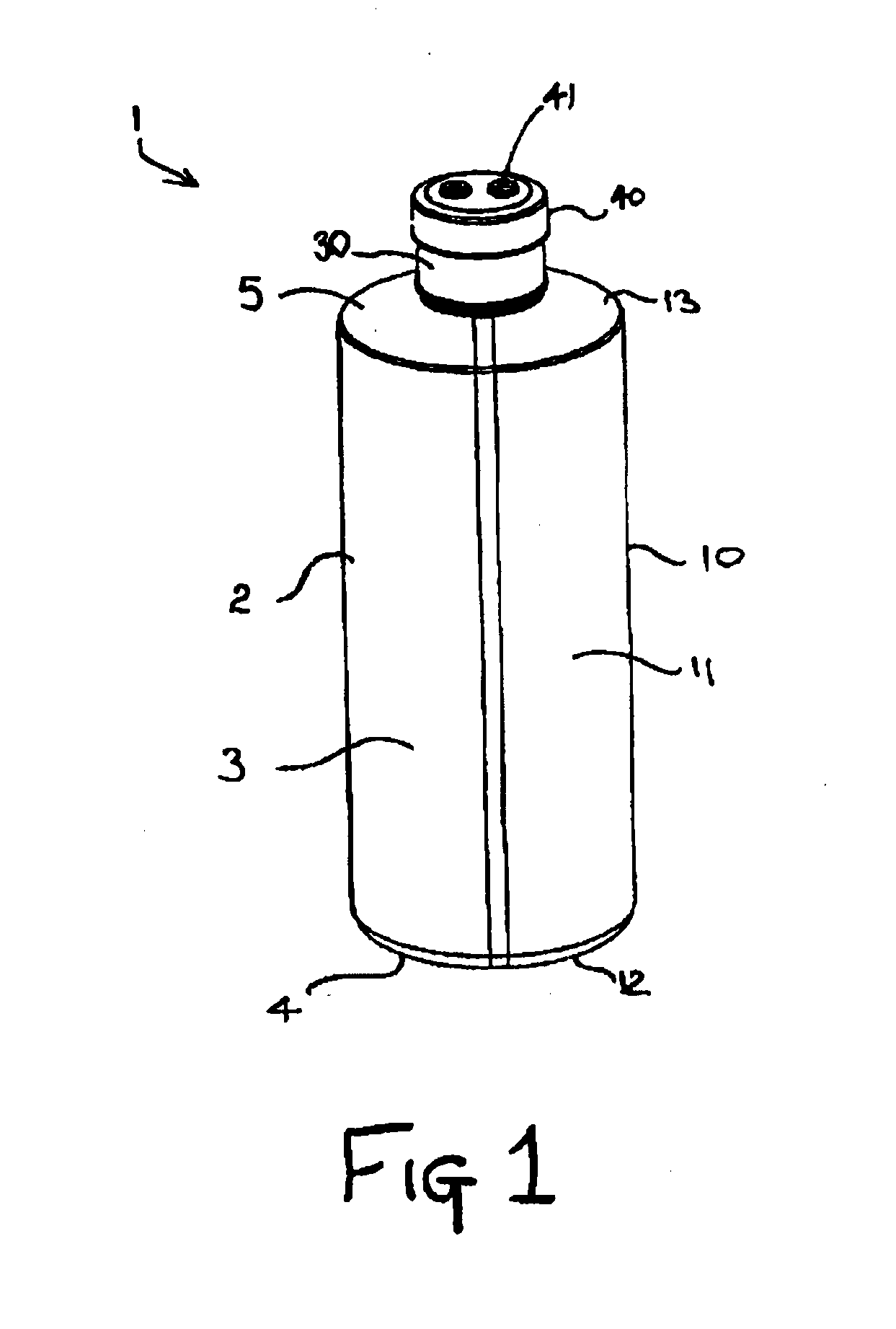

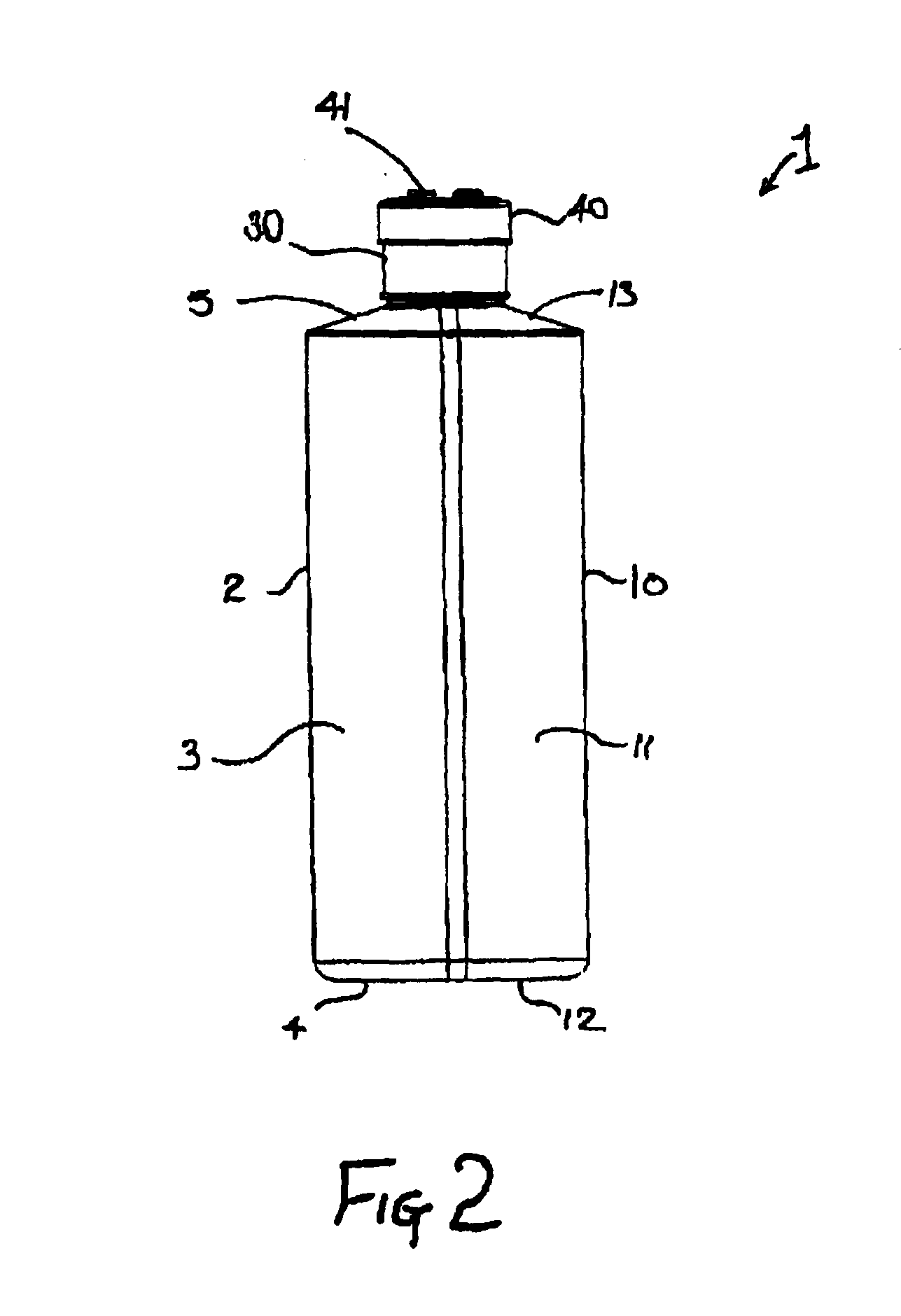

[0056]It will be appreciated that throughout the description of the preferred embodiments, like reference numerals have been used to denote like components. Referring to FIGS. 1 to 9, there is shown various views of a stabilised chlorine dioxide composition dispensing container 1 according to the first preferred embodiment. In this embodiment the container 1 is configured to dispense a stabilized chlorine dioxide composition and additives in liquid form.

[0057]The dispensing container 1 includes a first chamber 2 having a side wall 3 extending upwardly from a base 4. The side wall terminates at a first chamber upper end 5. A first chamber opening 6 is provided on the first chamber upper end 5. The first chamber is substantially semi-circular in cross-section as best seen in FIG. 5. A flat section 7 of the side wall 3 includes a pair of spaced apart engagement tabs 8 and a pair of spaced apart engagement recesses 9 which may have retentive elements in their design.

[0058]The dispensing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com