Burner igniting system for gas stove

a technology for igniting systems and gas stoves, which is applied in the direction of combustion processes, lighting and heating apparatus, combustion regulation, etc., can solve the problems of increasing manufacturing costs, and achieve the effect of preventing the burner igniting system from being easily damaged, reducing manufacturing costs, and simplifying the structure or configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

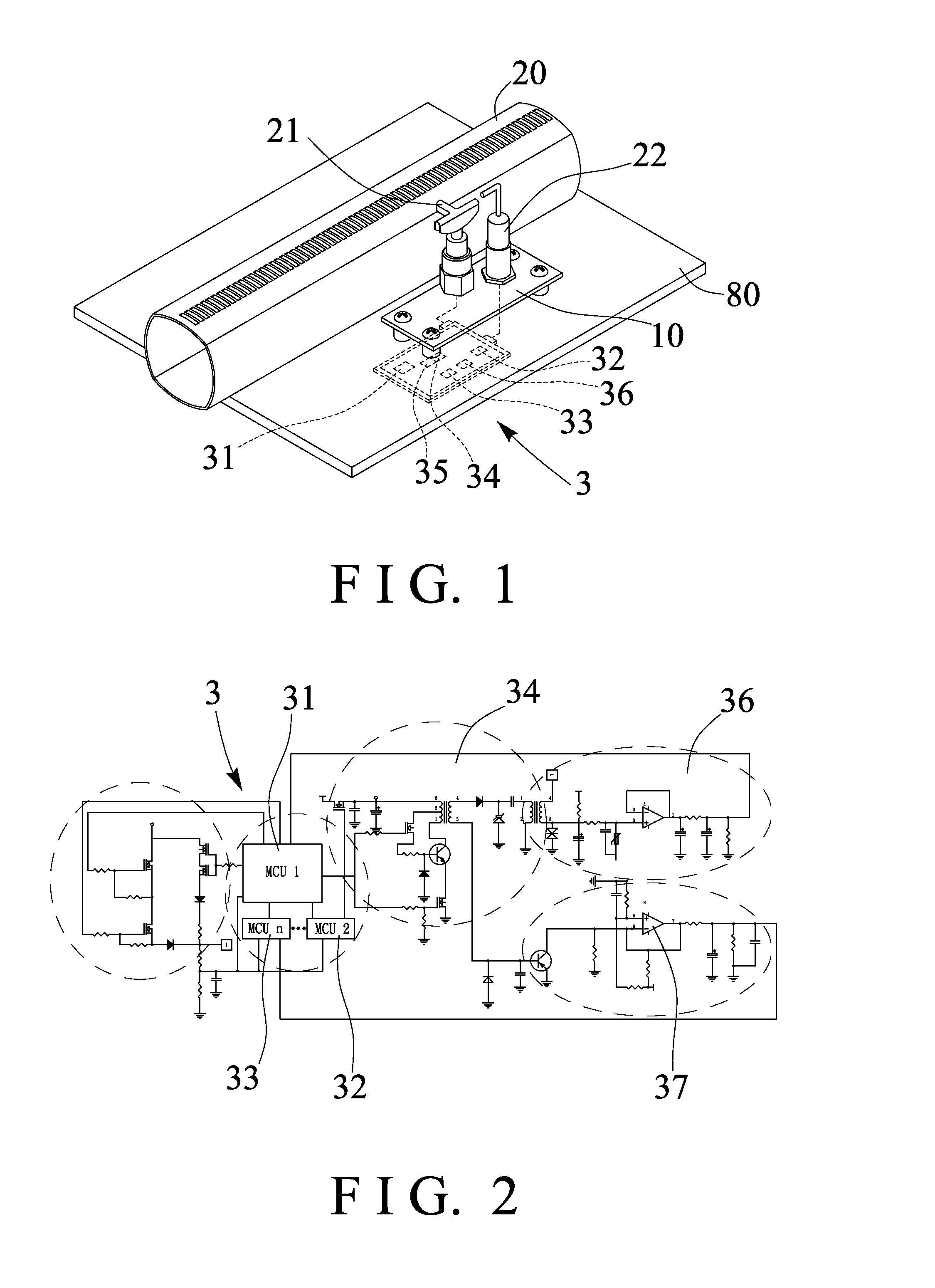

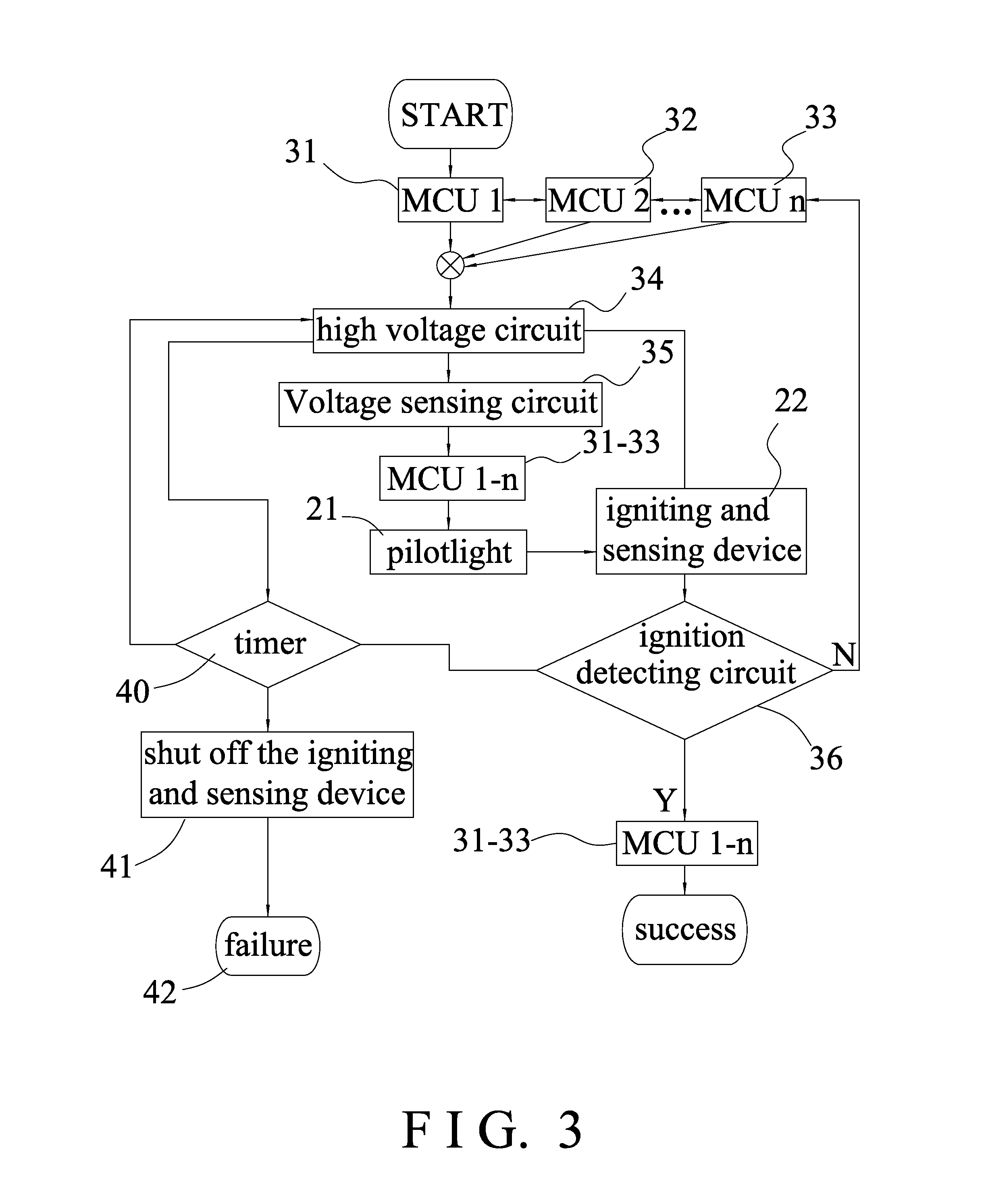

[0017]Referring to the drawings, and initially to FIG. 1, a burner igniting system in accordance with the present invention comprises a platform or base plate 10 disposed or attached or mounted or secured in a gas stove 80, in which the other parts or portions of the gas stove 80 are typical and are not related to the present invention and will not be described in further details and have not been shown or illustrated, a burner 20 disposed or attached or mounted or secured in the gas stove 80, a pilot light 21 disposed or attached or mounted or secured on the base plate 10 for supplying a flame to the burner 20, and an igniting and sensing device 22 also disposed or attached or mounted or secured on the base plate 10 for igniting the pilot light 21 and for sensing the presence of flame on the pilot light 21. It is to be noted that only the igniting and sensing device 22 is required to be provided for both igniting the pilot light 21 and sensing the presence of flame on the pilot lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com