Resonating element, resonator, electronic device, electronic apparatus, moving vehicle and method of manufacturing resonating element

a technology of resonators and components, applied in the field of resonators, can solve the problems of reducing the effective area reducing the rigidity of the vibrating portion, and deteriorating the impact resistance or the like, so as to achieve the effect of simple processing step, impact resistance, and resistance to vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

of Vibrating Element

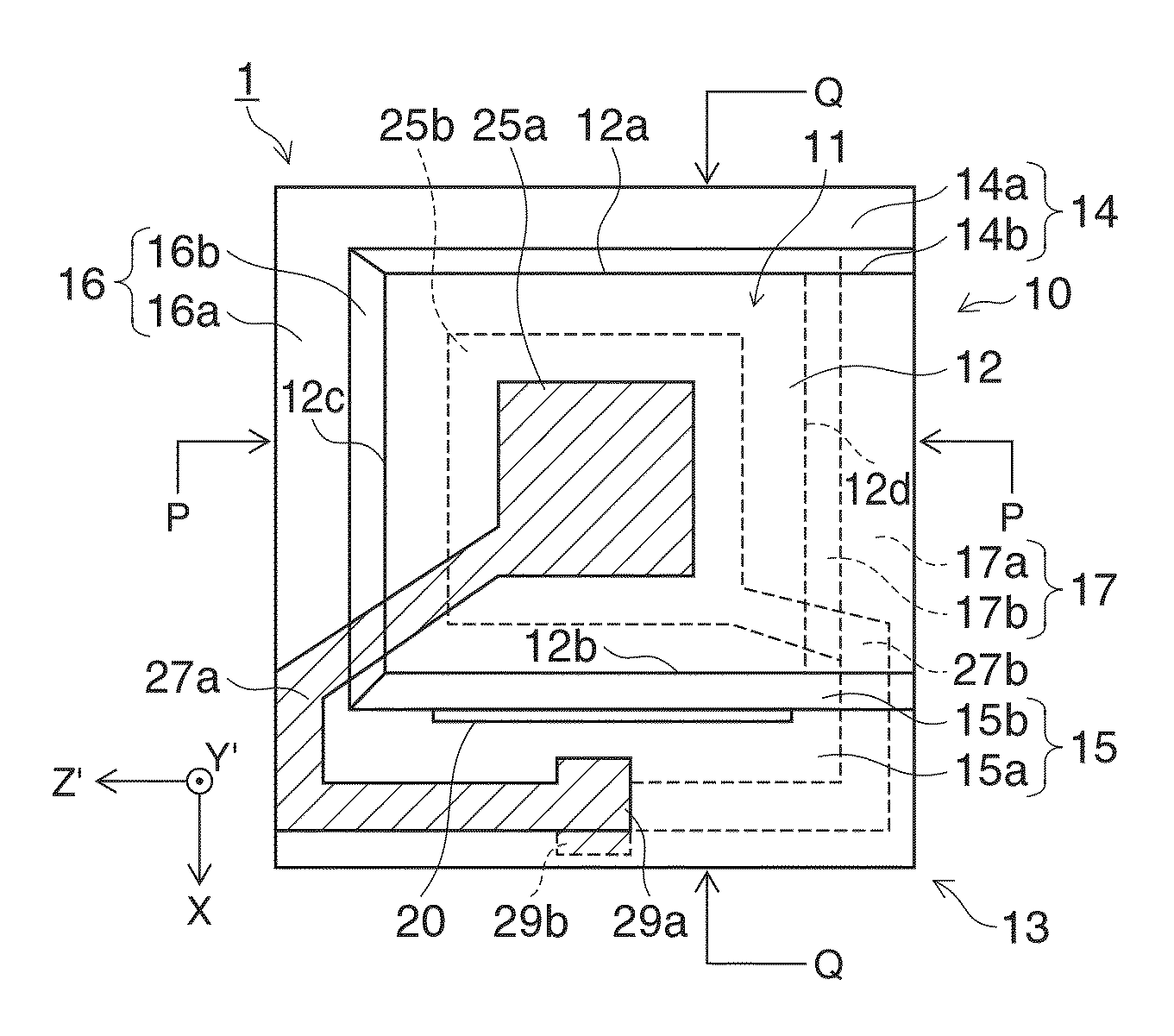

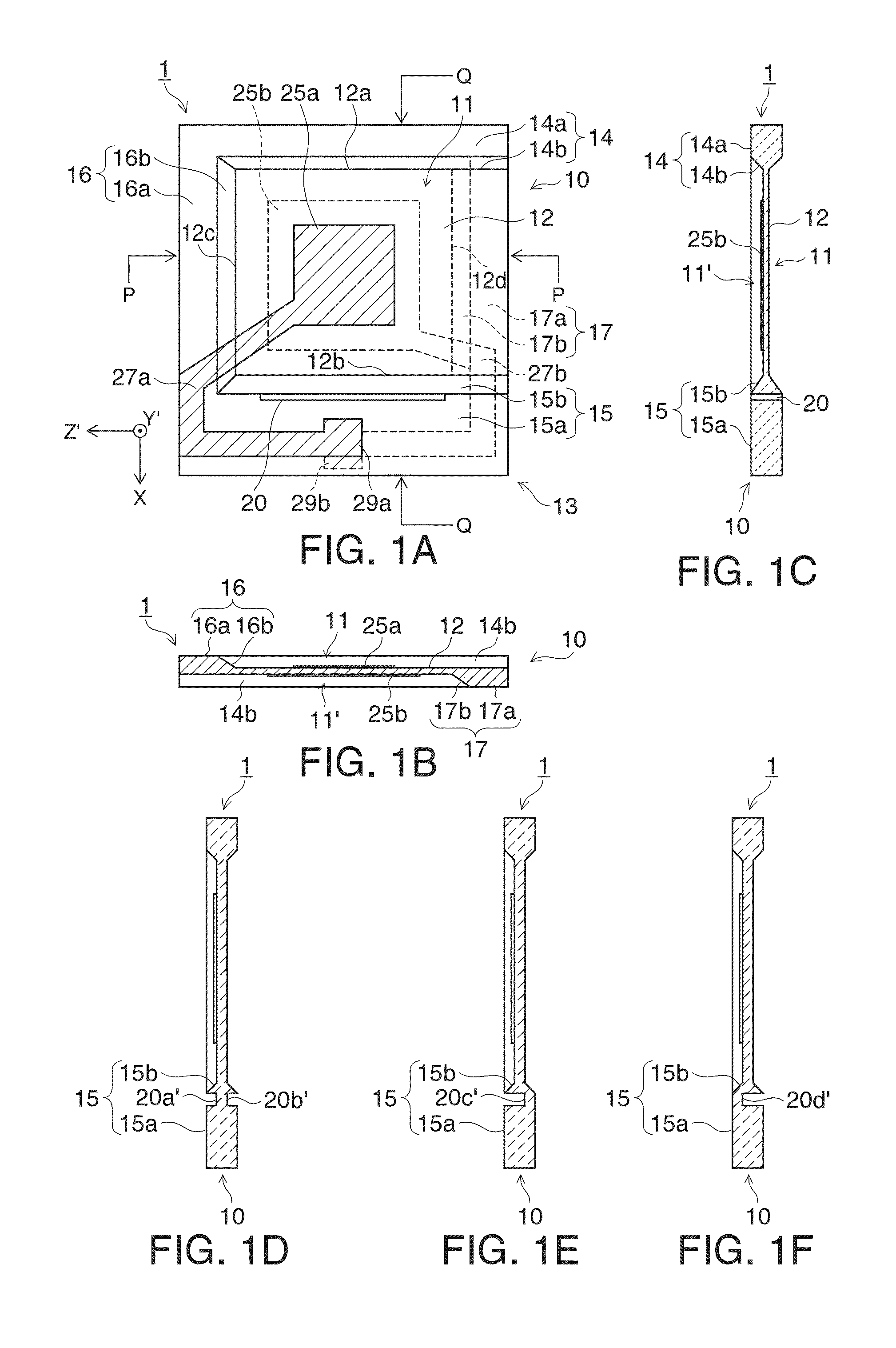

[0134]FIGS. 6A to 6C are schematic views illustrating the structure of a piezoelectric vibrating element 3 according to a third embodiment. FIG. 6A is a plan view of the piezoelectric vibrating element 3, FIG. 6B is a cross-sectional view of a P-P cross-section as seen from the positive X-axis direction, and FIG. 6C is a cross-sectional view of a Q-Q cross-section as seen from the positive Z′-axis direction.

[0135]The piezoelectric vibrating element 3 is different from the piezoelectric vibrating element 1 illustrated in FIGS. 1A to 1F in that two stress-mitigating slits 20a and 20b are formed in parallel in the third thick-walled portion 15. That is, the first slit 20a is formed in the plane of the third thick-walled body 15a, and the second slit 20b is formed in the plane of the third slope portion 15b.

[0136]By forming individual slits in the plane of the third thick-walled body 15a and the plane of the third slope portion 15b, respectively, it is possible to b...

fourth embodiment

of Vibrating Element

[0138]FIGS. 8A to 8F are schematic views illustrating the structure of a piezoelectric vibrating element 4 according to a fourth embodiment. FIG. 8A is a plan view of the piezoelectric vibrating element 4, FIG. 8B is a cross-sectional view of a P-P cross-section as seen from a positive X-axis direction, and FIG. 8C is a cross-sectional view of a Q-Q cross-section as seen from a positive Z′-axis direction.

[0139]The piezoelectric vibrating element 4 includes a piezoelectric substrate 10 including a vibrating portion 12 having a thin-walled rectangular vibrating region and a thick-walled portion 13 having a thickness greater than that of the vibrating portion 12, integrated with the vibrating portion 12, excitation electrodes 25a and 25b formed on the front and rear surfaces (both principal surfaces) of the vibrating portion 12, respectively, and lead electrodes 27a and 27b that respectively extend from the excitation electrodes 25a and 25b toward pad electrodes 29a...

fifth embodiment

of Vibrating Element

[0171]FIGS. 12A to 12C are schematic views illustrating the structure of a piezoelectric vibrating element 6 according to a fifth embodiment. FIG. 12A is a plan view of the piezoelectric vibrating element 6, FIG. 12B is a cross-sectional view of a P-P cross-section as seen from the positive X-axis direction, and FIG. 12C is a cross-sectional view of a Q-Q cross-section as seen from the positive Z′-axis direction.

[0172]The piezoelectric vibrating element 6 is different from the piezoelectric vibrating element 4 illustrated in FIGS. 8A to 8F in that the stress-mitigating slit 20 is formed at a different position. In this embodiment, the slit 20 penetrates through the third slope portion 15b that is separated from the edge of the side 12a of the thin-walled vibrating portion 12. Unlike the piezoelectric vibrating element 4, the slit 20 is formed so as to be separated from both edges of the third slope portion 15b rather than forming the slit 20 in the third slope po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency-aging characteristics | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com