Method for filling bags with granules

a technology of granules and bags, applied in the field of methods for filling bags with granules, can solve the problems of impaired stacking property of bags and insufficient utilization of space, and achieve the effects of reducing the number of pallets required for transportation, improving stackability of filled granule bags, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

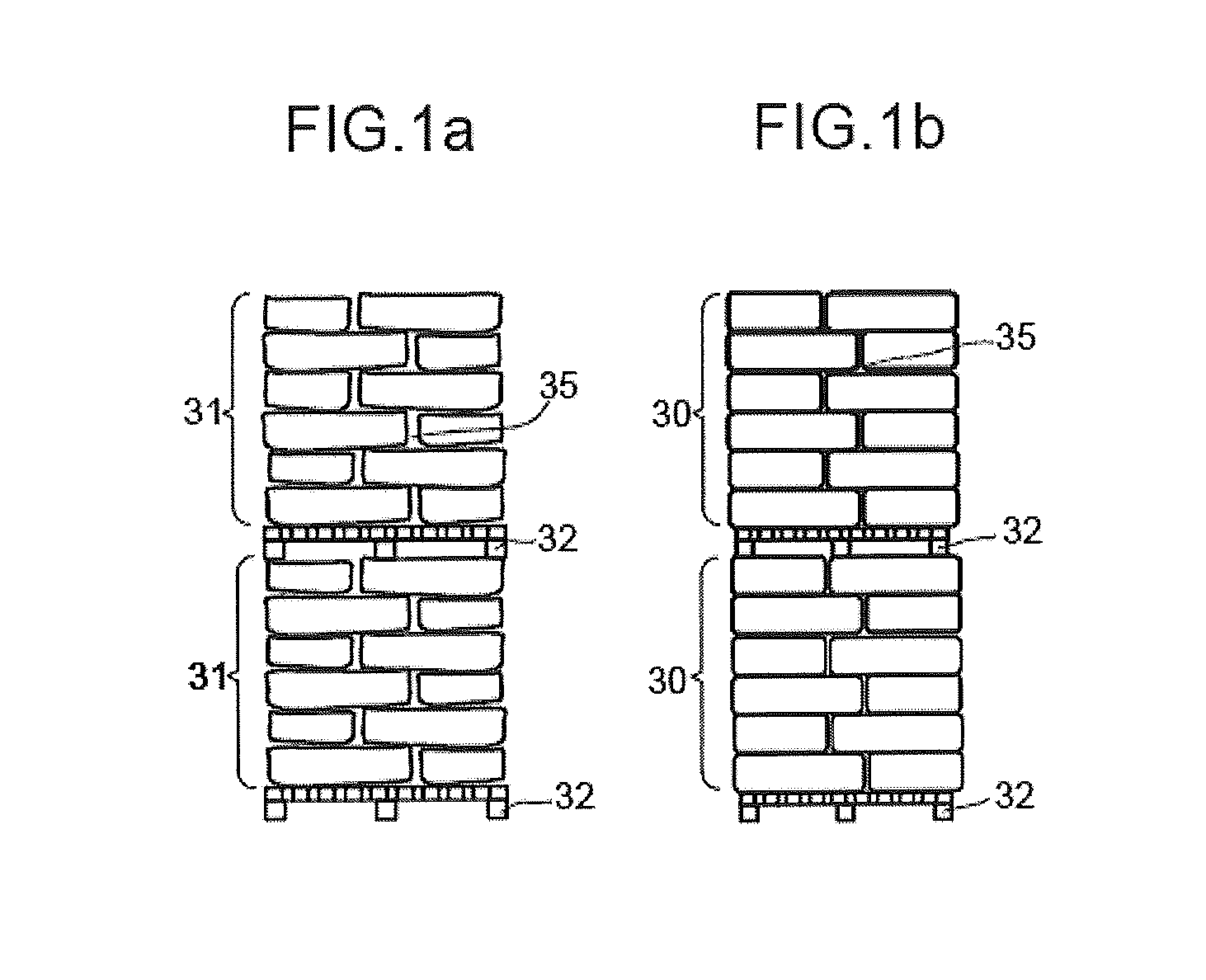

[0044]FIG. 1a shows a palletized stack of granule bags which have been filled by a method according to the prior art.

[0045]FIG. 1a shows granule bags 31 which have been filled by a method according to the prior art. The granule bags 31 are stacked in six layers on a pallet 32. Located on this stack is a further pallet 32 having a further six layers of granule bags 31. Unused hollow spaces 35 between the bags 31 are clearly noticeable. Furthermore, the format of each individual bag 31 varies greatly and there are to some extent considerable deviations from the ideal cuboidal format. Further layers of bags 31 can no longer be deposited safely on the stack.

[0046]FIG. 1b shows a palletized stack of bags which have been filled and formatted by the method according to the invention.

[0047]FIG. 1b illustrates six layers of bags 30 on a pallet 32. Placed on top of this stack is a further pallet 32, on which likewise six layers of bags 30 are arranged. On account of the virtually cuboidal for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com