Firearm Suppressor

a technology of suppressors and firearms, applied in the direction of weapons, weapon components, etc., can solve the problems of receiving hostile fire, affecting the accuracy of fire, and deafening the shooter and others nearby, so as to reduce the sound level, prevent any loss of accuracy, and attenuate the sound waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]The following description is of the best mode presently contemplated for carrying out the invention. This description is not to be taken in a limiting sense, but is made merely for the purpose of describing one or more preferred embodiments of the invention. The scope of the invention should be determined with reference to the claims.

[0063]In the following description, forward is in the direction of fire of the rifle and rearward is towards the rifle butt.

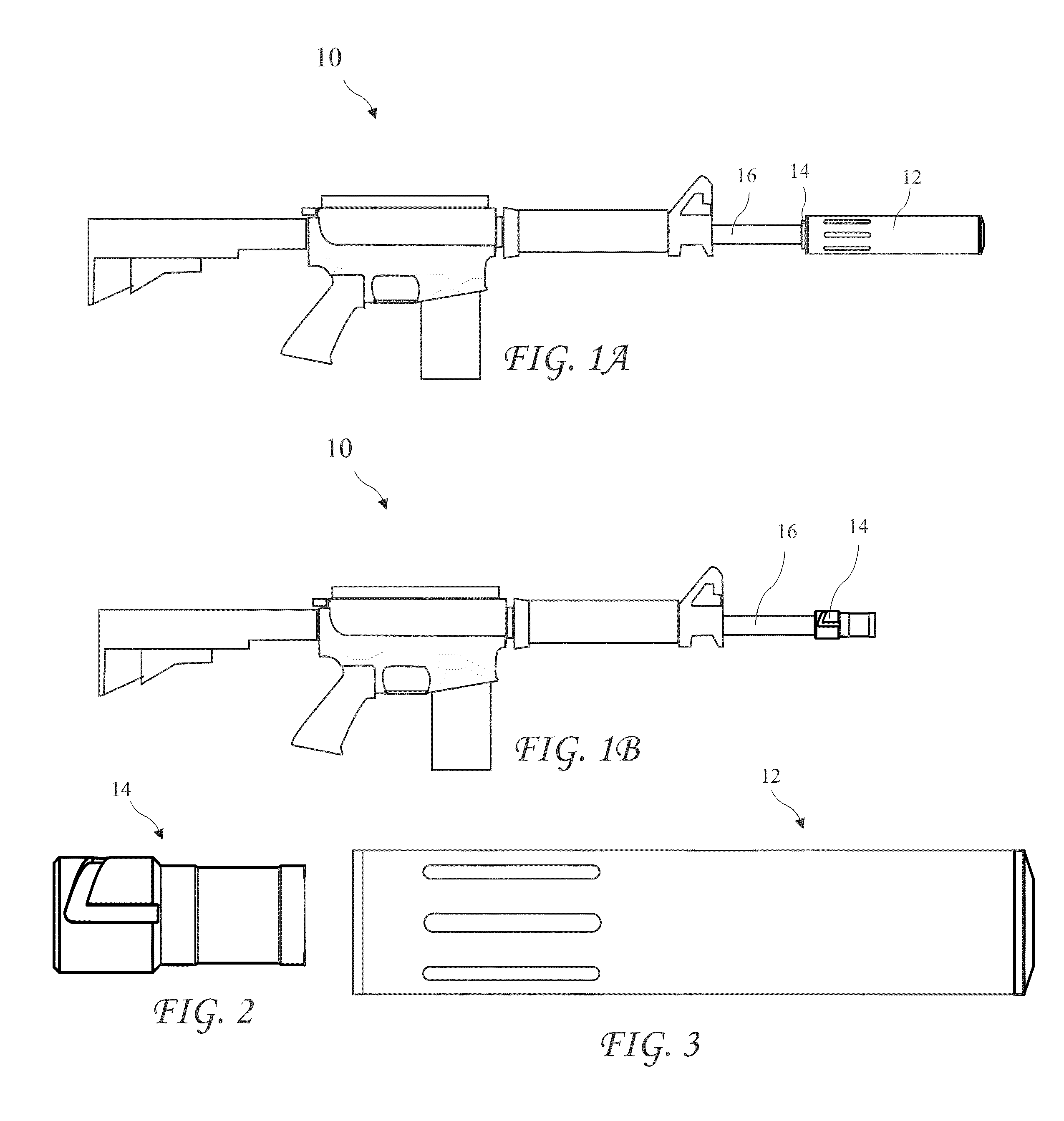

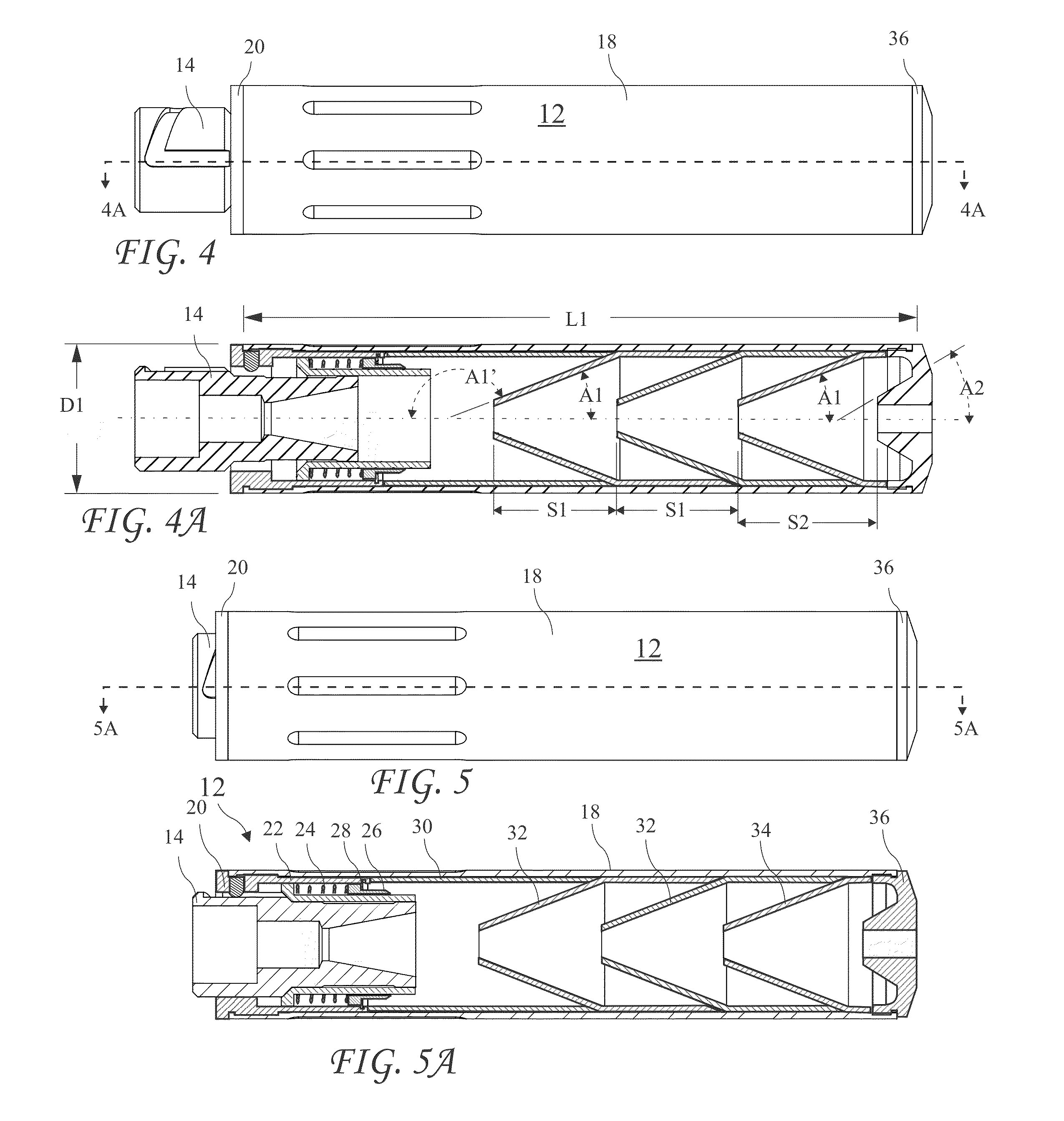

[0064]A side view of a rifle 10 and suppressor 12 according to the present invention is shown in FIG. 1, a side view of the rifle 10 with the suppressor 12 removed and showing a muzzle adapter 14 for the suppressor 12 is shown in FIG. 1B, a side view of the muzzle adapter 14 alone is shown in FIG. 2, and. a side view of the suppressor 12 alone is shown in FIG. 3. The suppressor 12 is attached to the muzzle adapter 14 by a quick disconnect mount 14.

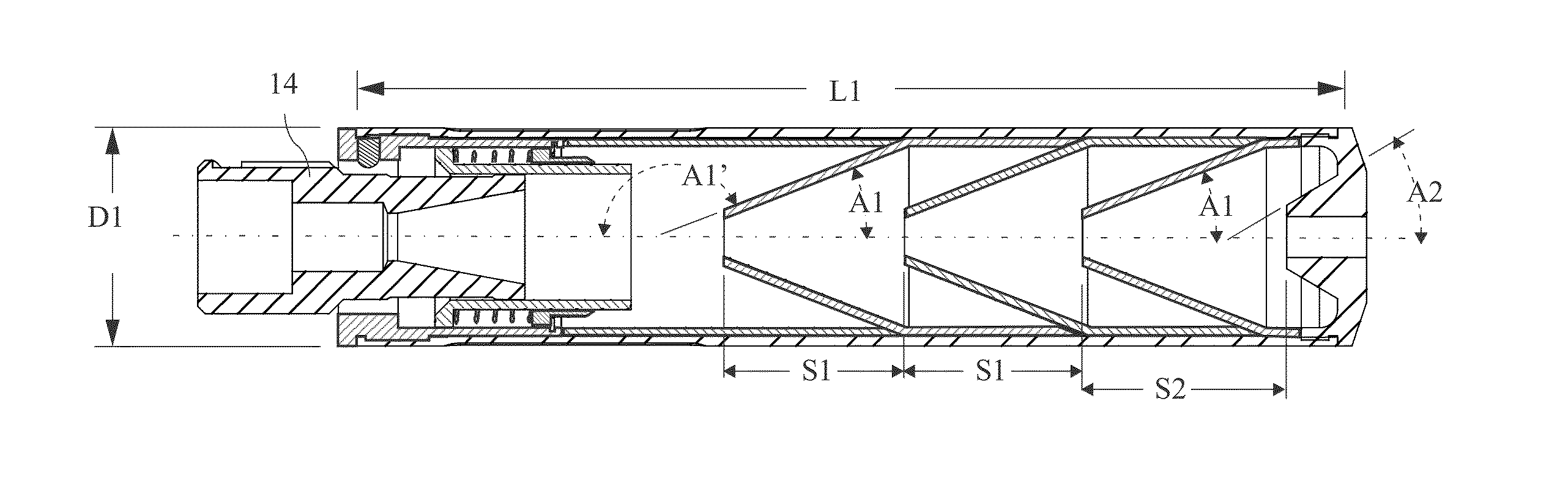

[0065]A detailed side view of the suppressor 12 partially attached to the muzzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com