Bottom plate structure for installing faucet

a faucet and bottom plate technology, applied in the field of faucets, can solve the problems of reducing the service life of the faucet, and reducing the material waste during production, so as to reduce the waste of materials during production, reduce the production cost, and simplify the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The purpose, construction, features, functions and advantages of the present invention can be appreciated and understood more thoroughly through the following detailed description with reference to the attached drawings.

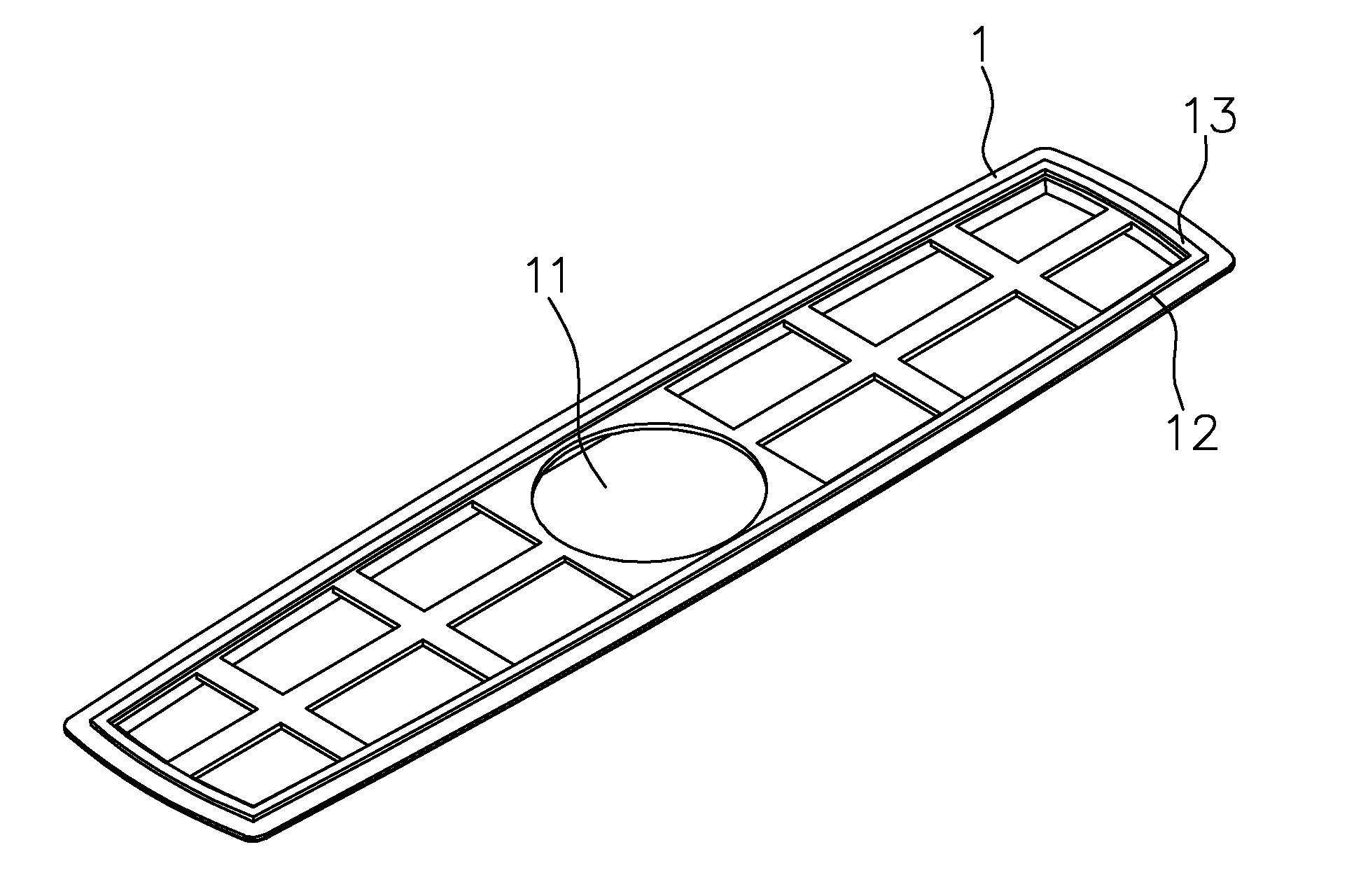

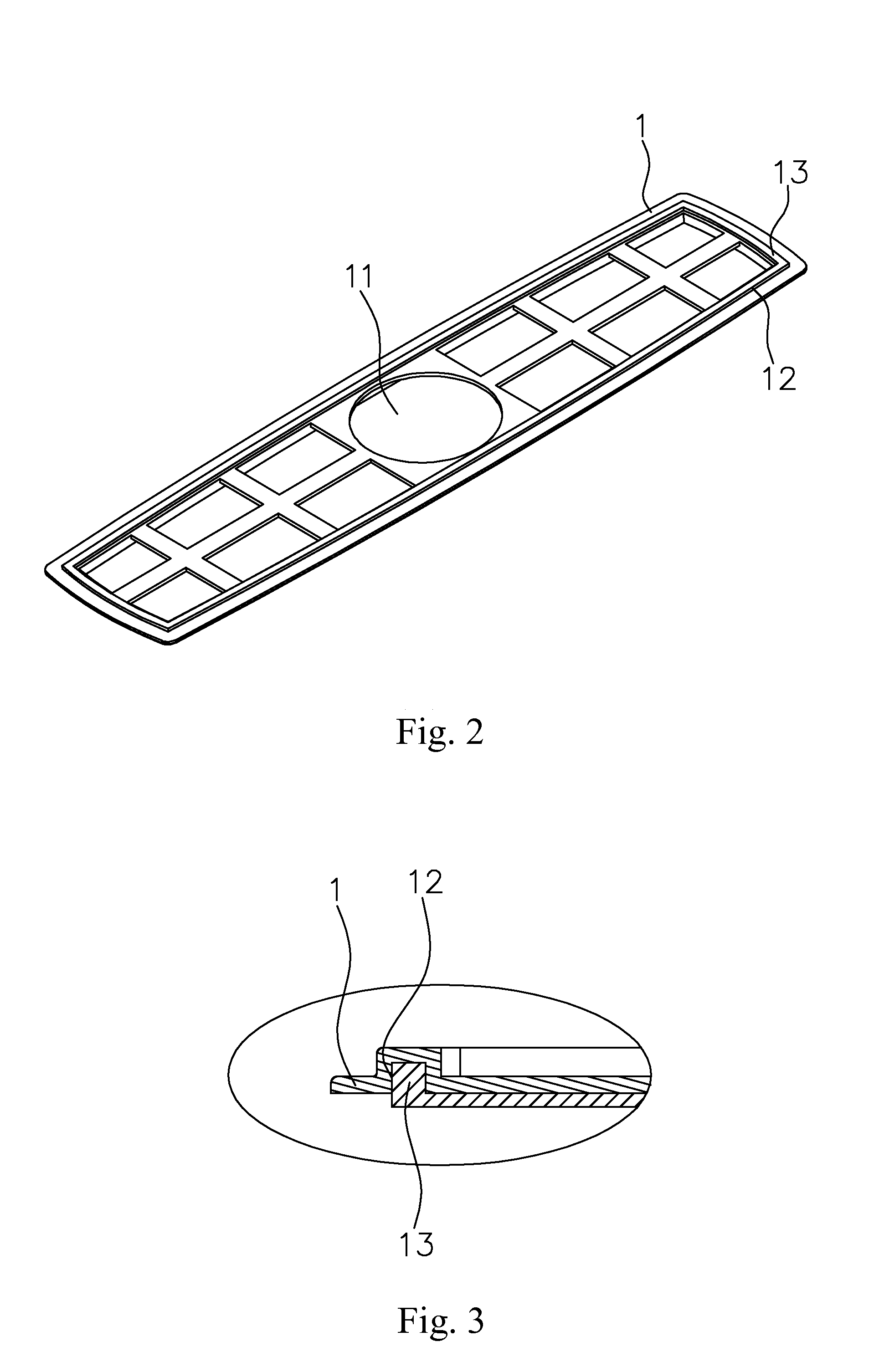

[0019]Refer to FIGS. 2 and 3 respectively for a schematic diagram of structure of a bottom plate used for installing a faucet according to the present invention, and a cross section view of a portion of structure of a bottom plate used for installing a faucet according to the present invention. As shown in FIGS. 2 and 3, the present invention provides a bottom plate structure used for installing a faucet, including: a bottom plate 1; an indent slot 12; and a filling strip 13. Wherein, the bottom plate 1 is formed by using low density polyethylene (LDPE) material, and similar to the prior art, the center of the bottom plate 1 is provided with an installation hole 11. In order to save material, the bottom plate 1 can adopt a hollow structure. The unique feature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com