Aircraft air chiller with reduced profile

a technology of air chiller and profile, which is applied in the direction of domestic cooling apparatus, lighting and heating apparatus, and circulation of cooling fluid, can solve the problems of condensation collection and removal, large amount of available space in the galley, so as to reduce the overall foot print and efficient distribution of chilled air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

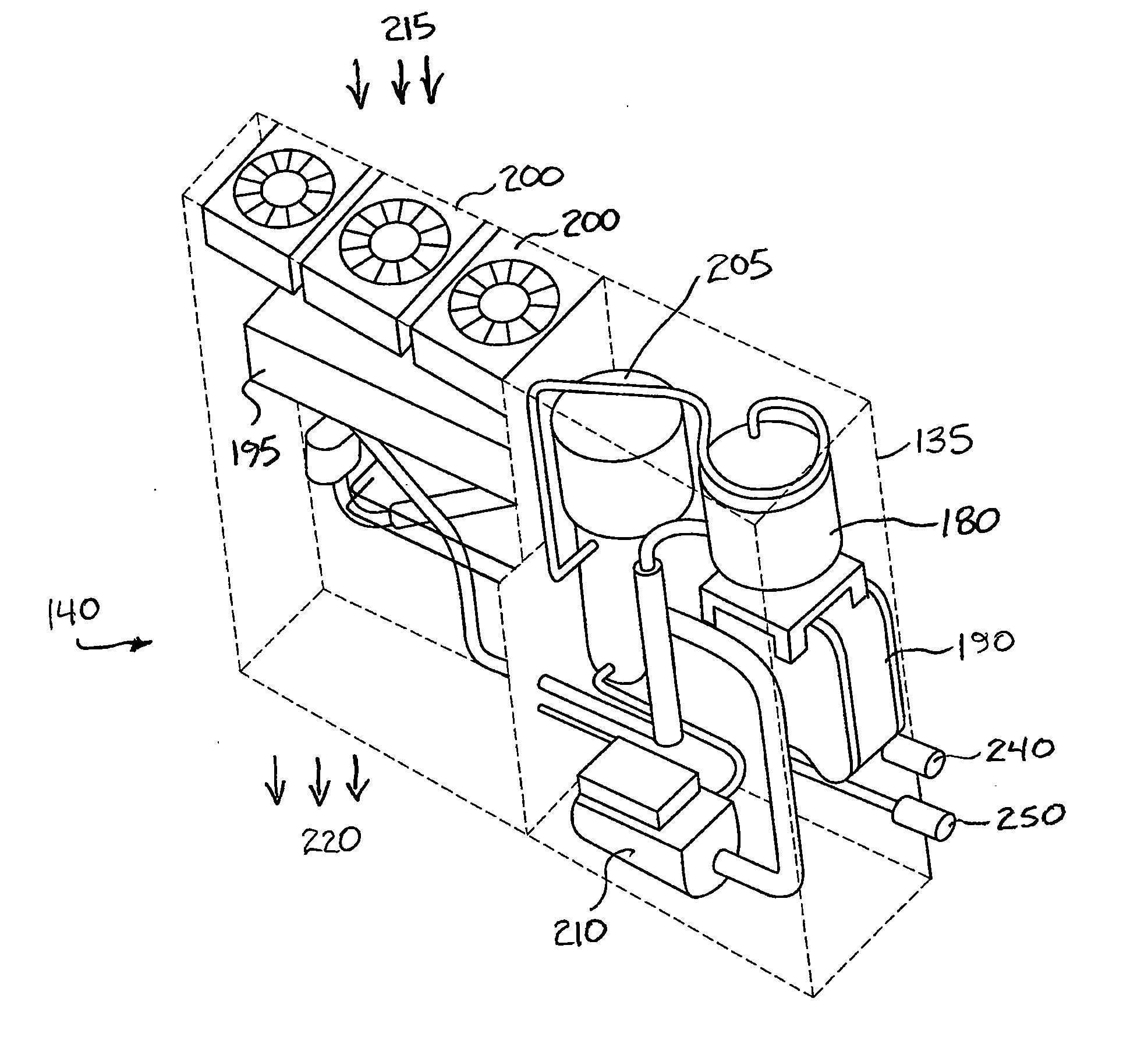

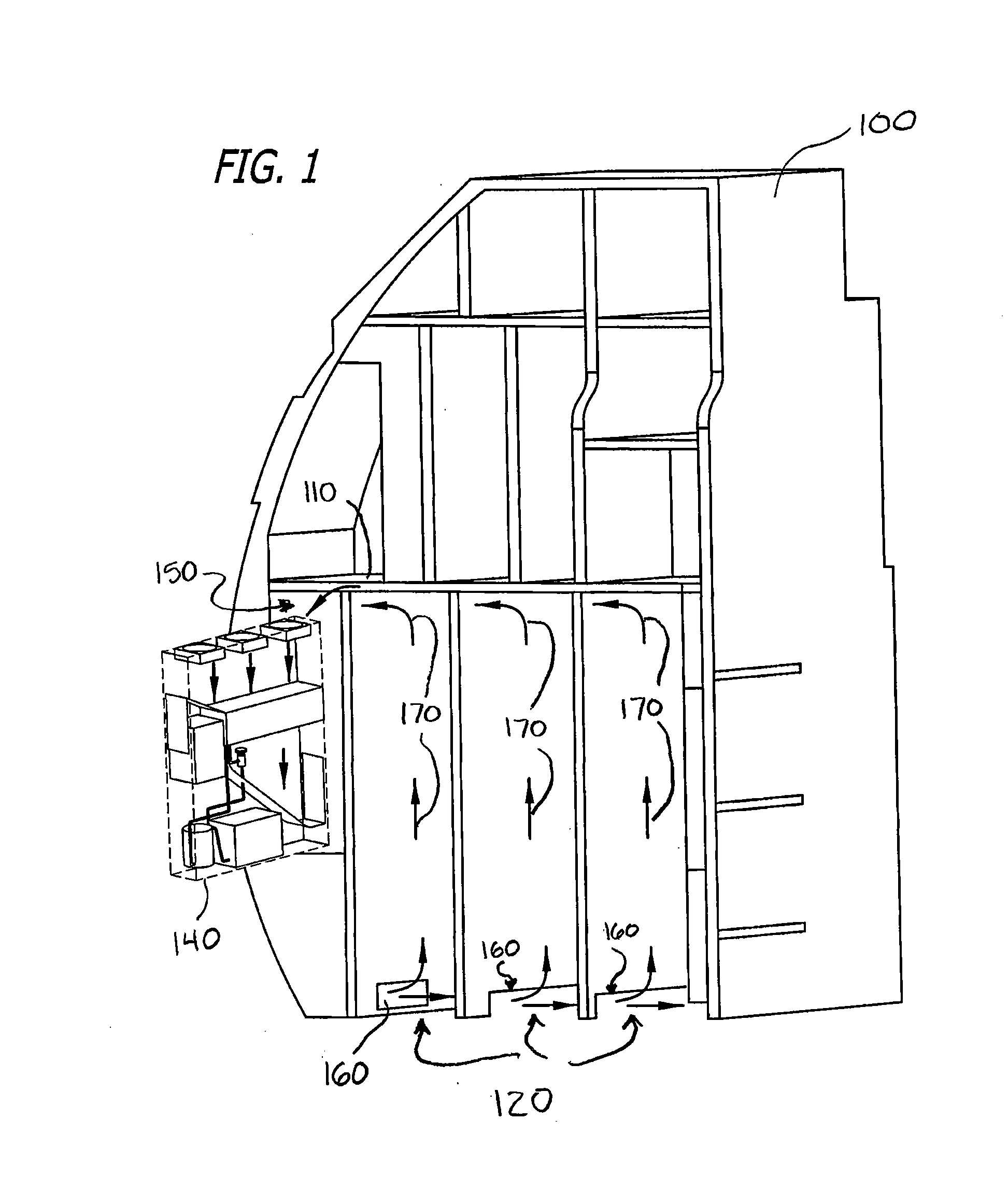

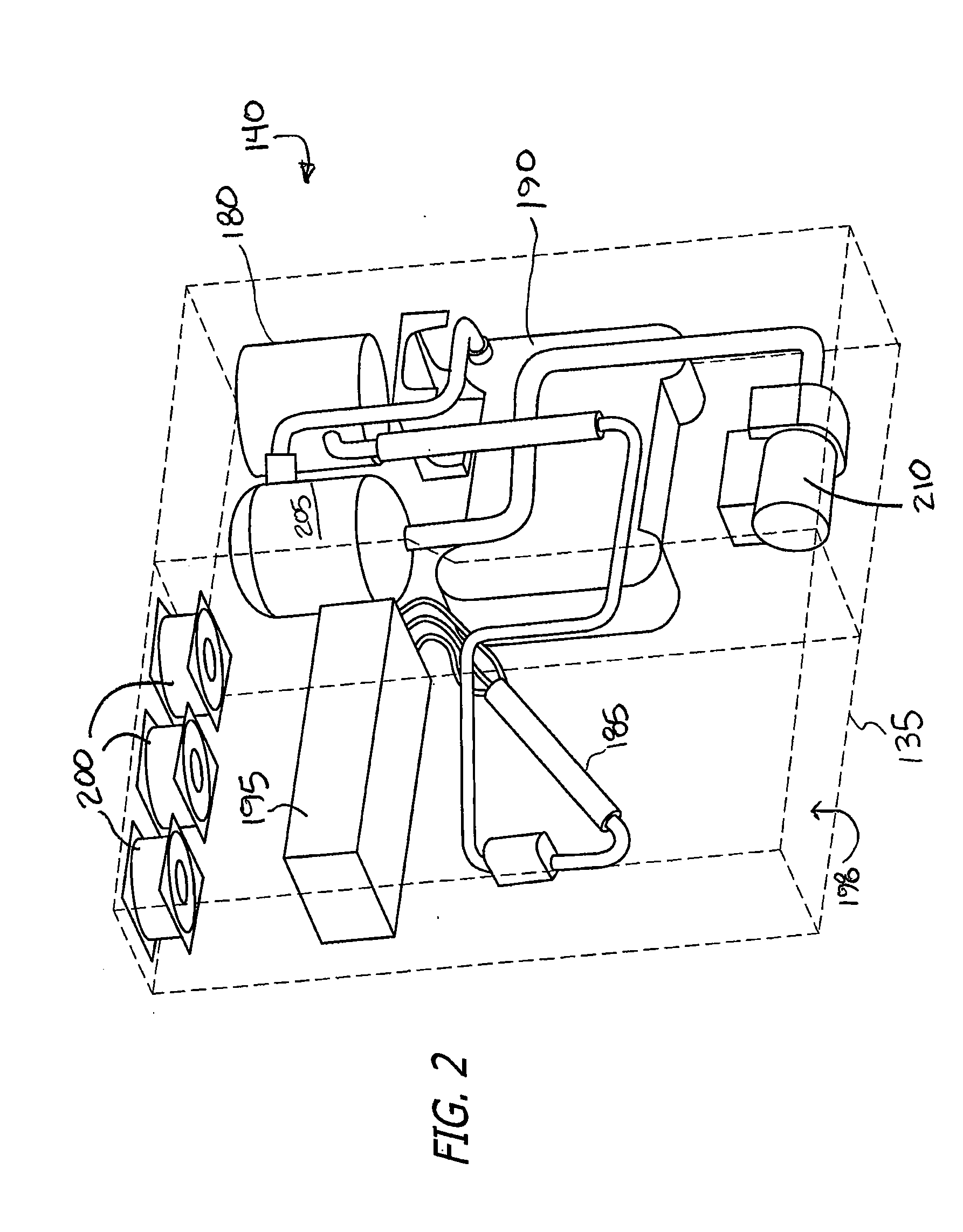

[0012]FIG. 1 illustrates a portion of an aircraft galley structural framework showing a position of the new chiller unit in relation to the beverage cart bays. The galley framework 100 includes a plurality of compartments above a work deck 110, where the space above the work deck 110 is reserved for various food service equipment such as coffee brewers, refrigerators, food storage, utensil storage, and the like. Below the work deck 110 is a series of bays 120 for housing beverage carts (not shown) that the flight attendants push down the aircraft's aisle(s) to bring food and beverages to the passengers. The beverage carts are intended to be kept at a temperature that allows the beverages and perishables inside to be preserved and served at an acceptable temperature. To maintain the carts at the proper temperature, a chiller unit 140 is located in a designated peripheral compartment 150 with air passages above and below for directing and receiving air from the bays 120. Each bay 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com