Substrate processing apparatus, method of manufacturing semiconductor device, and non-transitory computer-readable recording medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0021]Hereinafter, the present invention will be described with reference to the accompanying drawings.

[0022][Configuration of Apparatus]

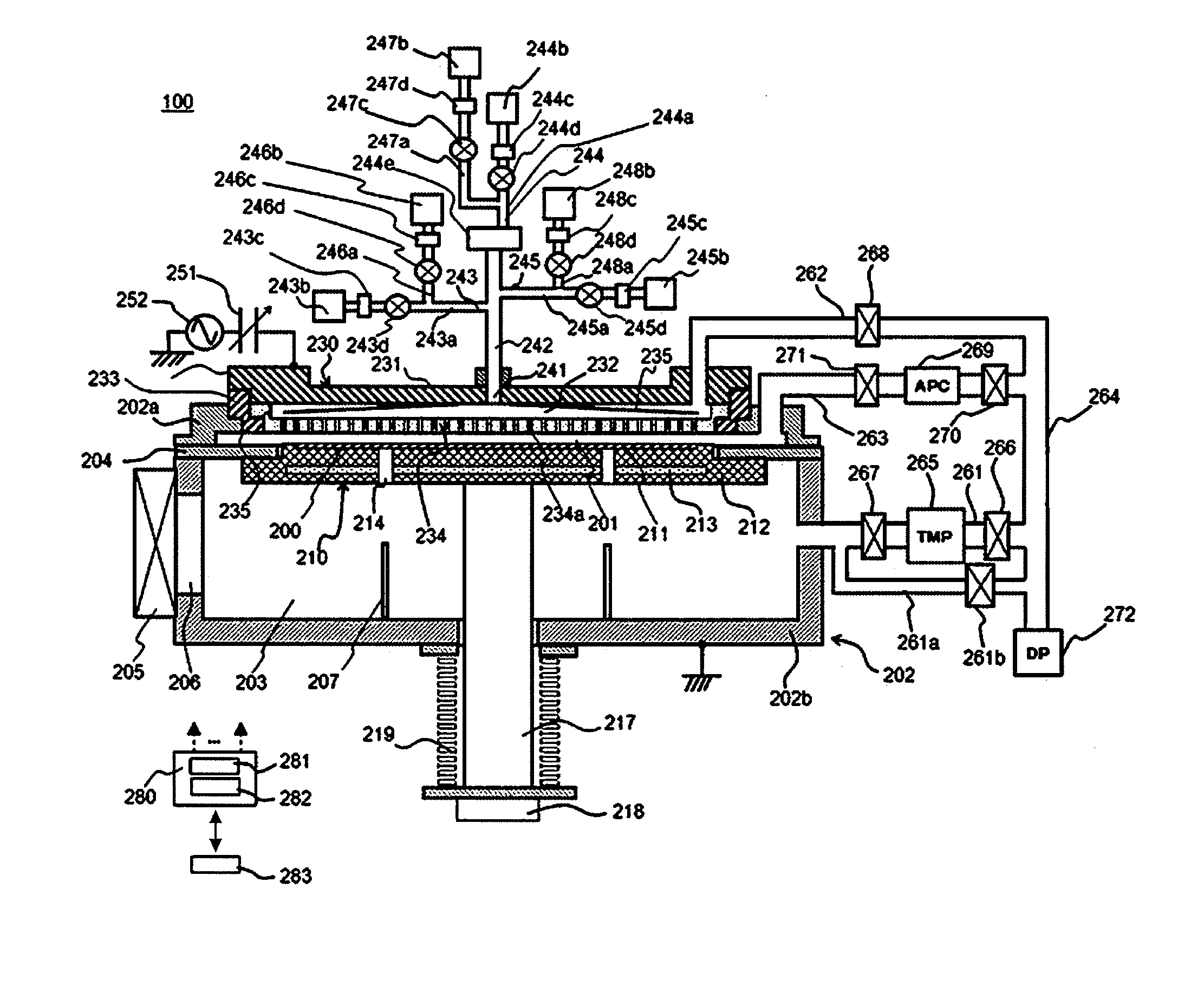

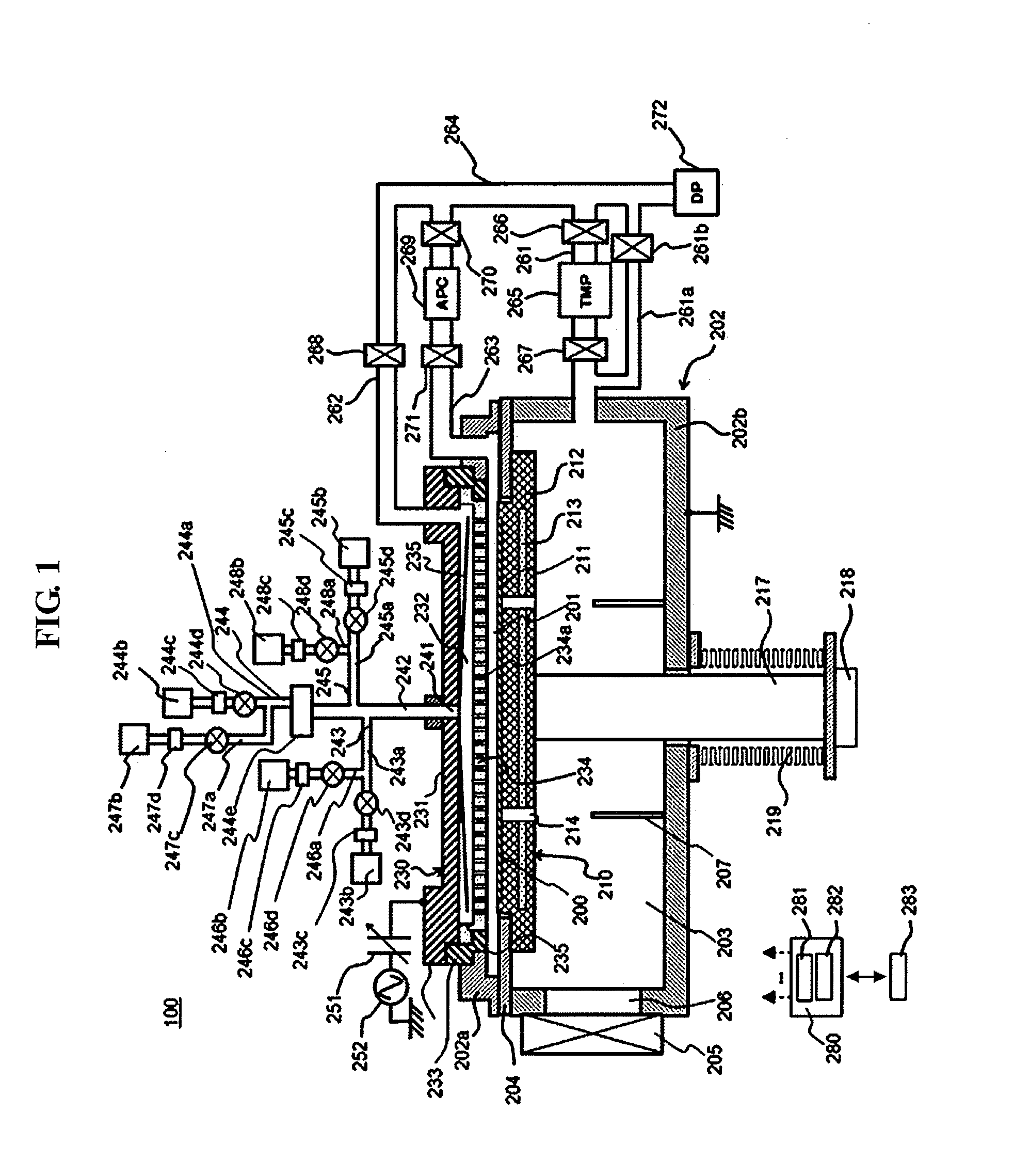

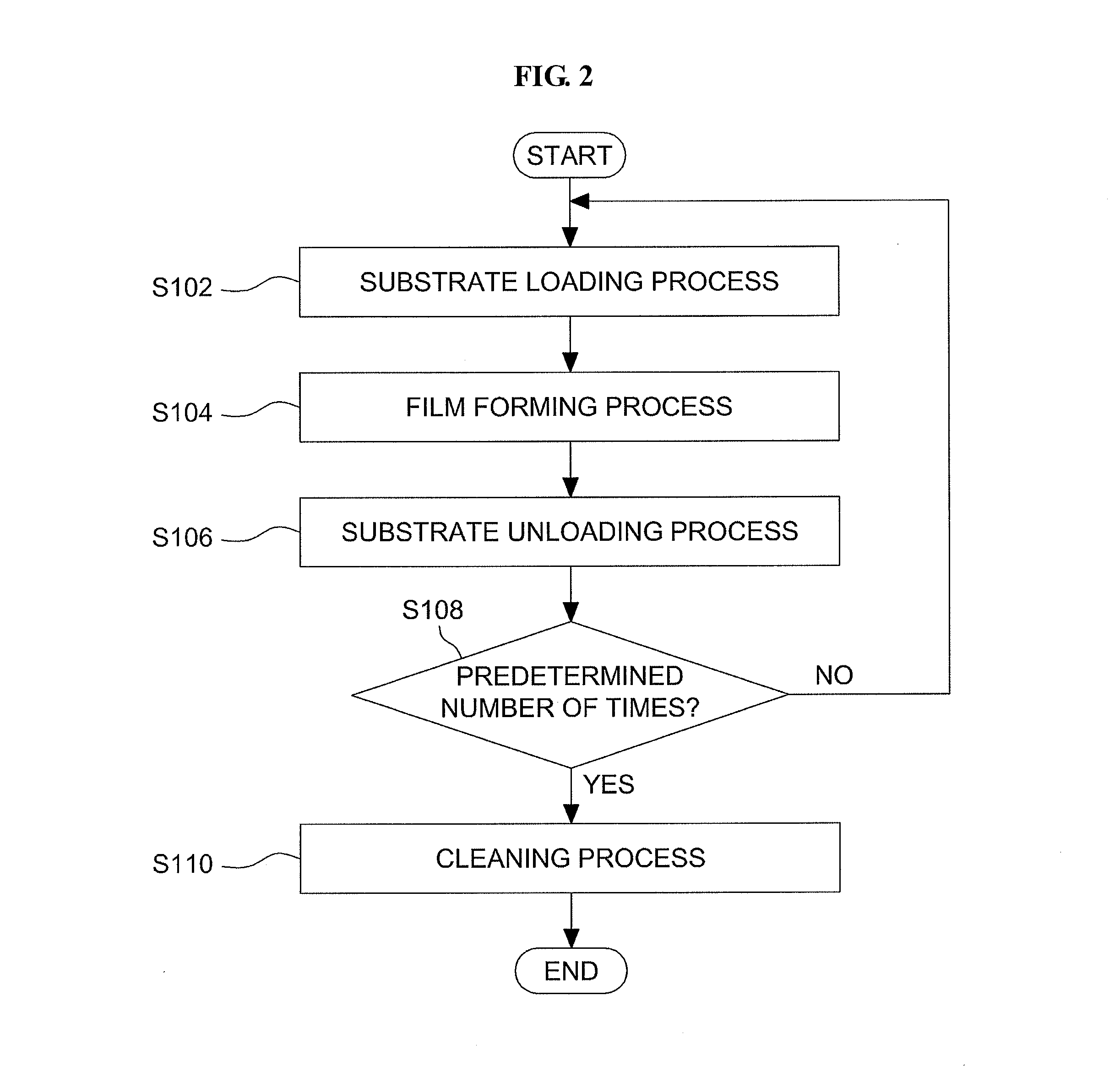

[0023]A configuration of substrate processing apparatus 100 according to an embodiment of the present invention is shown in FIG. 1. The substrate processing apparatus 100 is configured as a batch-type substrate processing apparatus as shown in FIG. 1.

[0024][Processing Container]

[0025]The substrate processing apparatus 100 includes a processing container 202 as shown in FIG. 1. The processing container 202 is configured as a flat sealed container whose cross-sectional surface has, for example, a circular shape. In addition, the processing container 202 is made of a metal material such as aluminum (Al), stainless steel (SUS), or the like. A processing space 201 that processes a wafer 200 such as a silicon wafer or the like as a substrate and a transfer space 203 through which the wafer 200 passes when the wafer 200 is transferred to the processing sp...

second embodiment

[0128]Next, the present invention will be described.

[0129][Apparatus Configuration]

[0130]A substrate processing apparatus 102 according to the second embodiment is shown in FIG. 5. In addition, the same reference numerals are used to designate the same configurations as in the substrate processing apparatus 100 according to the first embodiment, and thus description thereof will be omitted.

[0131]In the substrate processing apparatus 102 according to the second embodiment, an inert gas supply unit that supplies N2 gas between the TMP 265 and the valve 267 upstream from the TMP 265 in the exhaust pipe 261 is provided. The inert gas supply unit includes a supply pipe 290, an inert gas supply source 291 connected to the downstream side of the supply pipe 290, a valve 292 provided upstream from the inert gas supply source 291 in the supply pipe 290, and a mass flow controller (MFC) 293 which is provided between the inert gas supply source 291 and the valve 292 in the supply pipe 290. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com