Centrifugal multi-blade blower

a centrifugal multi-blade blower and multi-blade technology, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of impeller loss, air flow exfoliation in the inter-vane,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

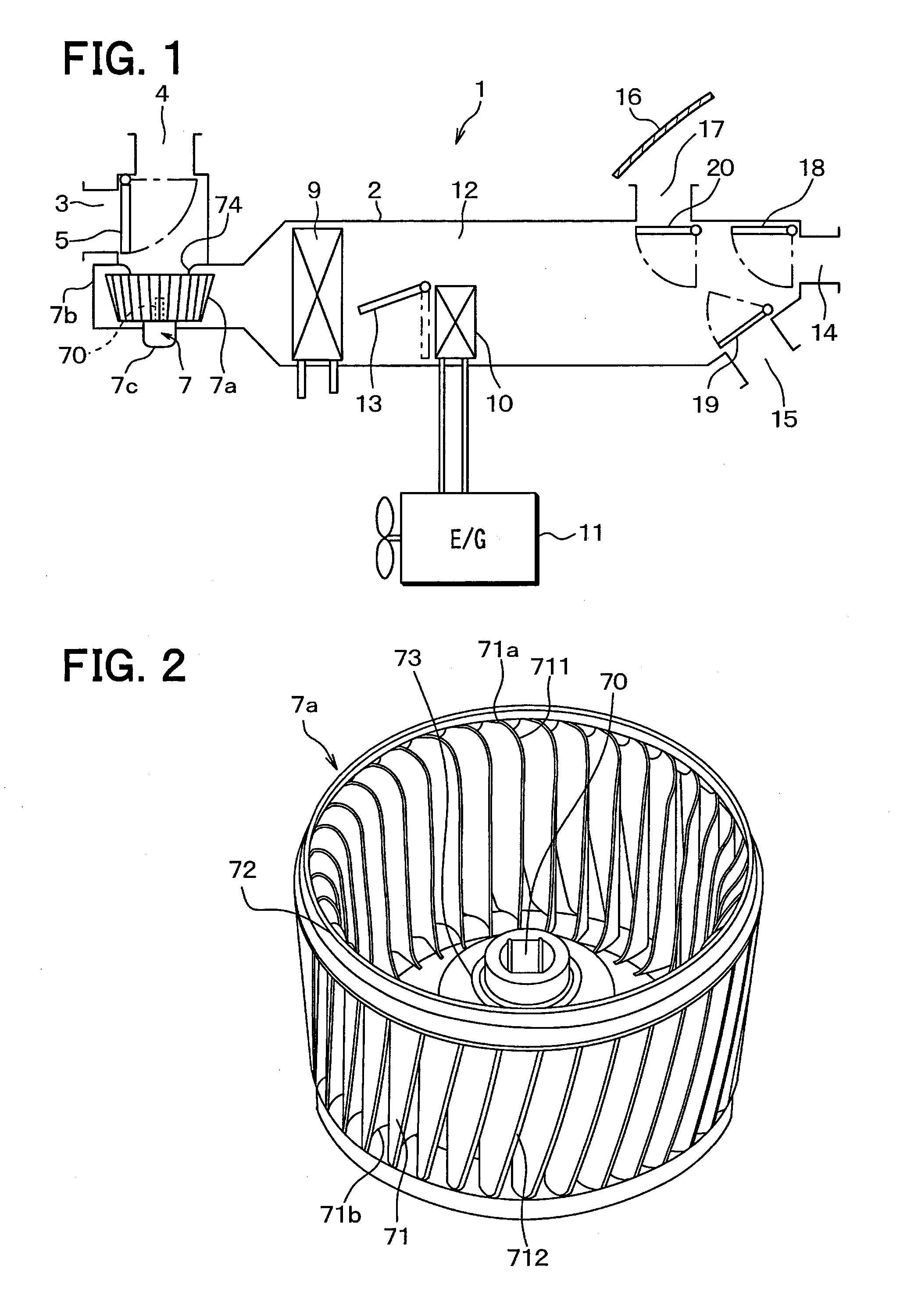

[0052]A first embodiment will be described below. In the present embodiment, a centrifugal multi-blade blower of the present disclosure is applied to an air-conditioning system 1 for a vehicle including a water-cooled engine.

[0053]As illustrated in FIG. 1, the air-conditioning system 1 includes an air-conditioning casing 2 that defines an air passage for blown air which is blown into a vehicle interior. At an uppermost stream side part of the air-conditioning casing 2 in an air flow direction, there are formed an inside air introduction port 3 for introducing inside air (vehicle interior air), and an outside air introduction port 4 for introducing outside air (vehicle exterior air), and there is provided an inside-outside air switch door 5 for selectively opening or closing these introduction ports 3, 4.

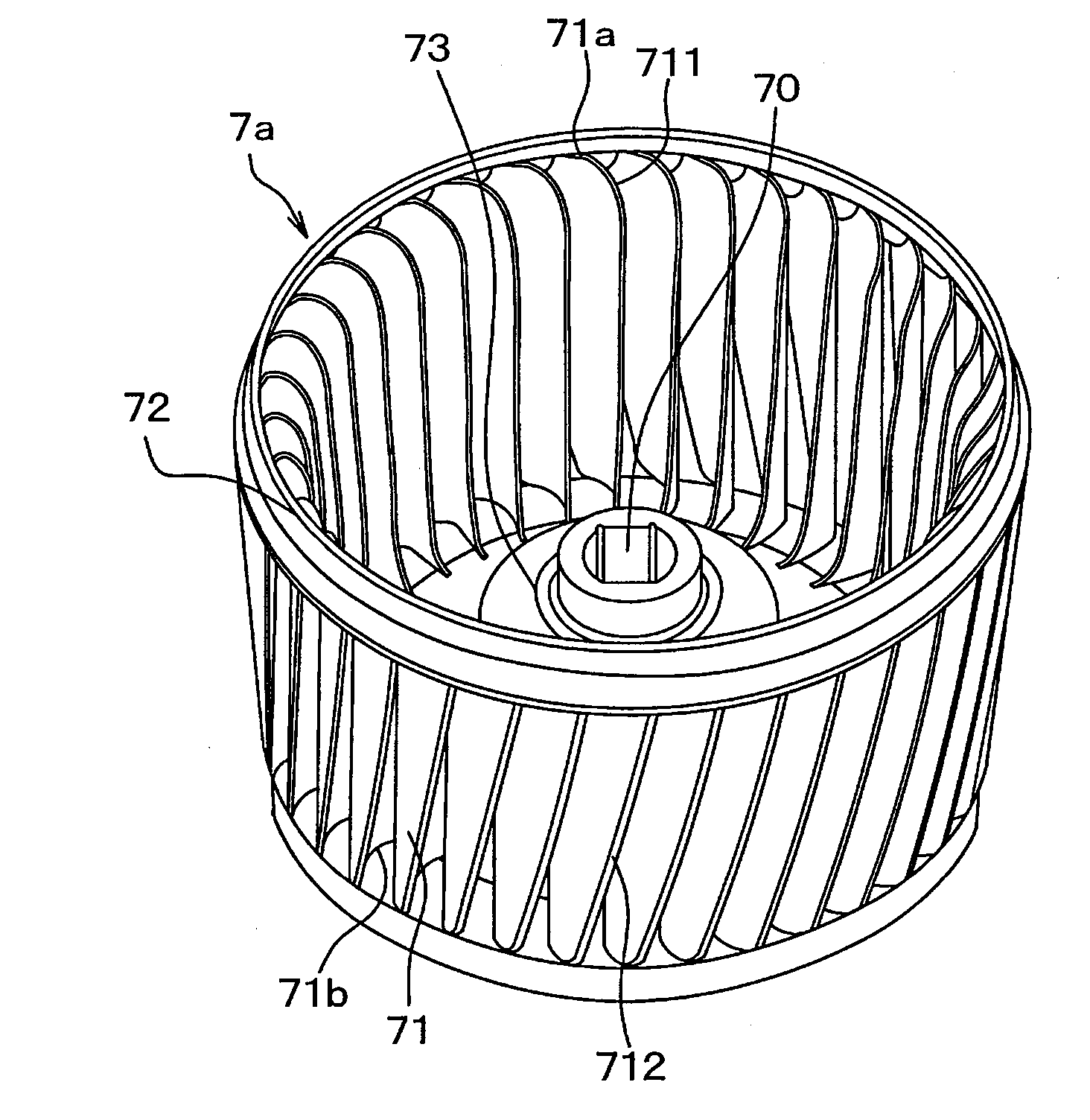

[0054]A blower 7 is disposed on a downstream side of the inside-outside air switch door 5 in an air flow direction, and the air introduced through the introduction ports 3, 4 is blow...

second embodiment

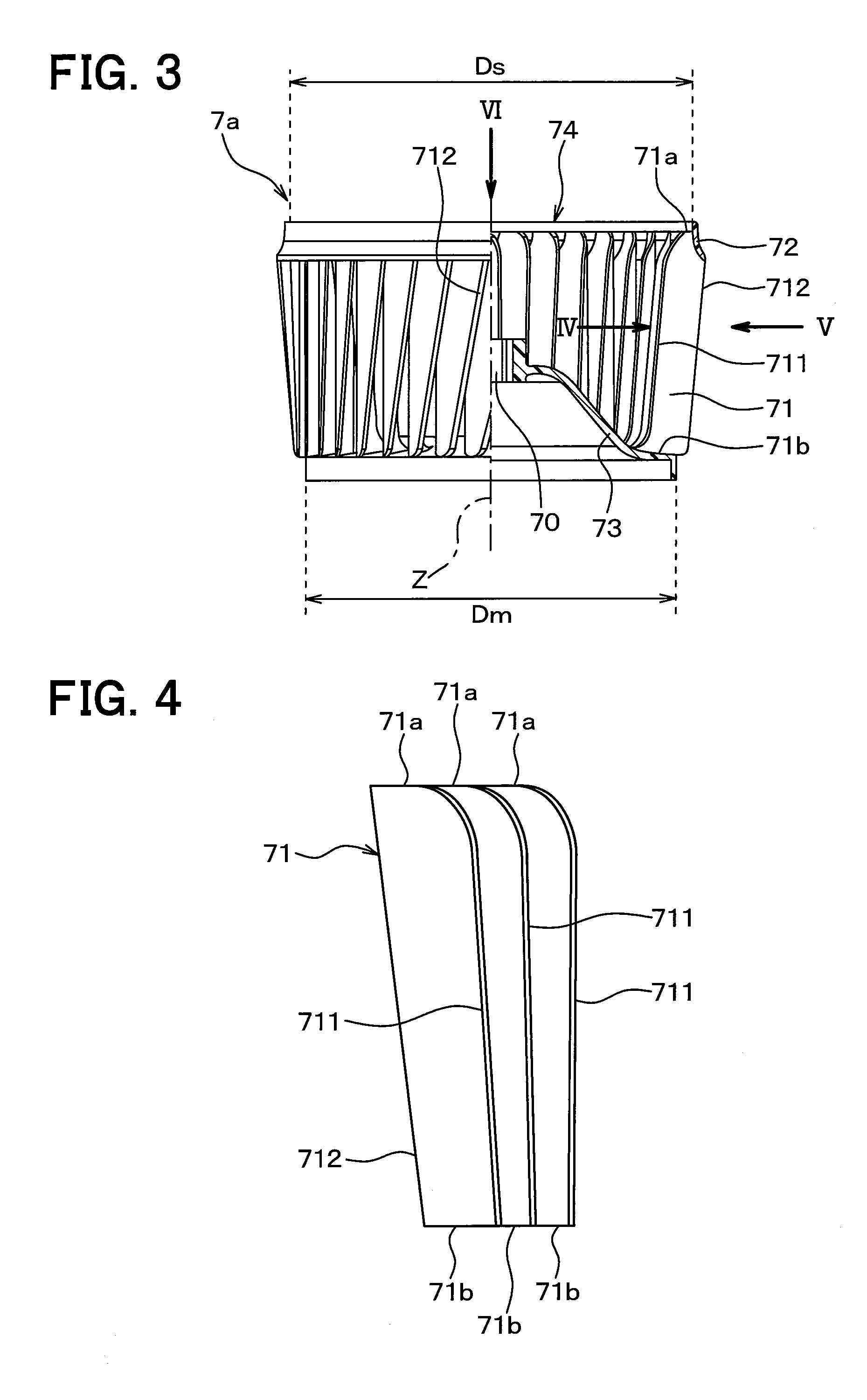

[0097]A second embodiment will be described below. In the present embodiment, an example of modification of the shape of the main plate 73 to the first embodiment will be described. In the present embodiment, explanation will be given with the description of a part similar or equivalent to the first embodiment omitted or simplified.

[0098]In an impeller 7a of the present embodiment, an outer peripheral diameter of a main plate 73 is made smaller than in the first embodiment as illustrated in a perspective view in FIG. 11, a half sectional view in FIG. 12, and a top view in FIG. 13. Specifically, in the present embodiment, as illustrated in FIG. 13, the outer peripheral diameter of the main plate 73 is made small such that the main plate 73 and a forward part 711a of an inner peripheral edge part 711 do not overlap with each other when the impeller 7a is viewed from the rotation axis direction.

[0099]More specifically, as illustrated in a meridian plane diagram in FIG. 14, a distance L...

third embodiment

[0103]A third embodiment will be described below. In the present embodiment, an example of modification of the shape of the impeller 7a to the first and second embodiments will be described. In the present embodiment, explanation will be given with the description of a part similar or equivalent to the first and second embodiments omitted or simplified.

[0104]In the present embodiment, as illustrated in FIG. 15, a ratio of an outer peripheral diameter D1 to an inner peripheral diameter d1 of an impeller 7a on a side plate 72-side (side-plate side inner-outer diameter ratio) is larger than a ratio of an outer peripheral diameter D2 to an inner peripheral diameter d2 of the impeller 7a on a main plate 73-side (main-plate side inner-outer diameter ratio) (D1 / d1>D2 / d2).

[0105]Specifically, in the present embodiment, outer peripheral edge parts 712 of vanes 71 are configured to be away from an axis Z of a rotation shaft 70 from the main plate 73-side toward the side plate 72-side, and inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com