Lubricating oil composition

a technology of lubricating oil and composition, which is applied in the direction of lubricant composition, additives, petroleum industry, etc., can solve the problems of low removal efficiency and increase wear amount, and achieve the effect of high fuel efficiency, durability and piston detergency in internal combustion engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

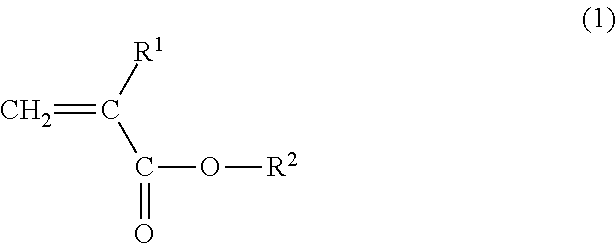

Method used

Image

Examples

examples

[0103]The present invention is described in more detail with reference to the following Examples. The present invention is not limited to the following Examples.

[Properties Measurement of Lubricating Oil Composition]

(1) Kinematic Viscosity (at 40° C. and 100° C.)

[0104]Measured according to ASTM D445.

(2) Viscosity Index of Base Oil

[0105]Measured according to “Test Method for Kinematic Viscosity of Petroleum Products” defined in JIS K 2283.

(3) CCS Viscosity of Composition

[0106]Measured according to ASTM D2602.

(4) NOACK Value of Composition

[0107]Measured according to ASTM D5800.

(5) HTHS Viscosity (High-Temperature High-Shear Viscosity), at 80° C., 100° C., 150° C.

[0108]Measured according to ASTM D4683.

(6) Phosphorus and Calcium Content

[0109]Measured according to JPI-5S-38-92.

[Properties Evaluation]

[0110]300 ml of a sample oil was heated in a heating tank at 100° C., and splashed on an aluminium plate arranged on the top of the heating tank and heated at 300° C. using feathers, and this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com