Pulsed hydraulic clothes washer

a technology of clothes washer and pulsating pump, which is applied in the direction of washing machine with receptacles, detergent compounding agents, liquid/gas/vapor textile treatment, etc., can solve the problems of frequent complex construction, high energy consumption of typical modern washing machines, and the possibility of mechanical failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

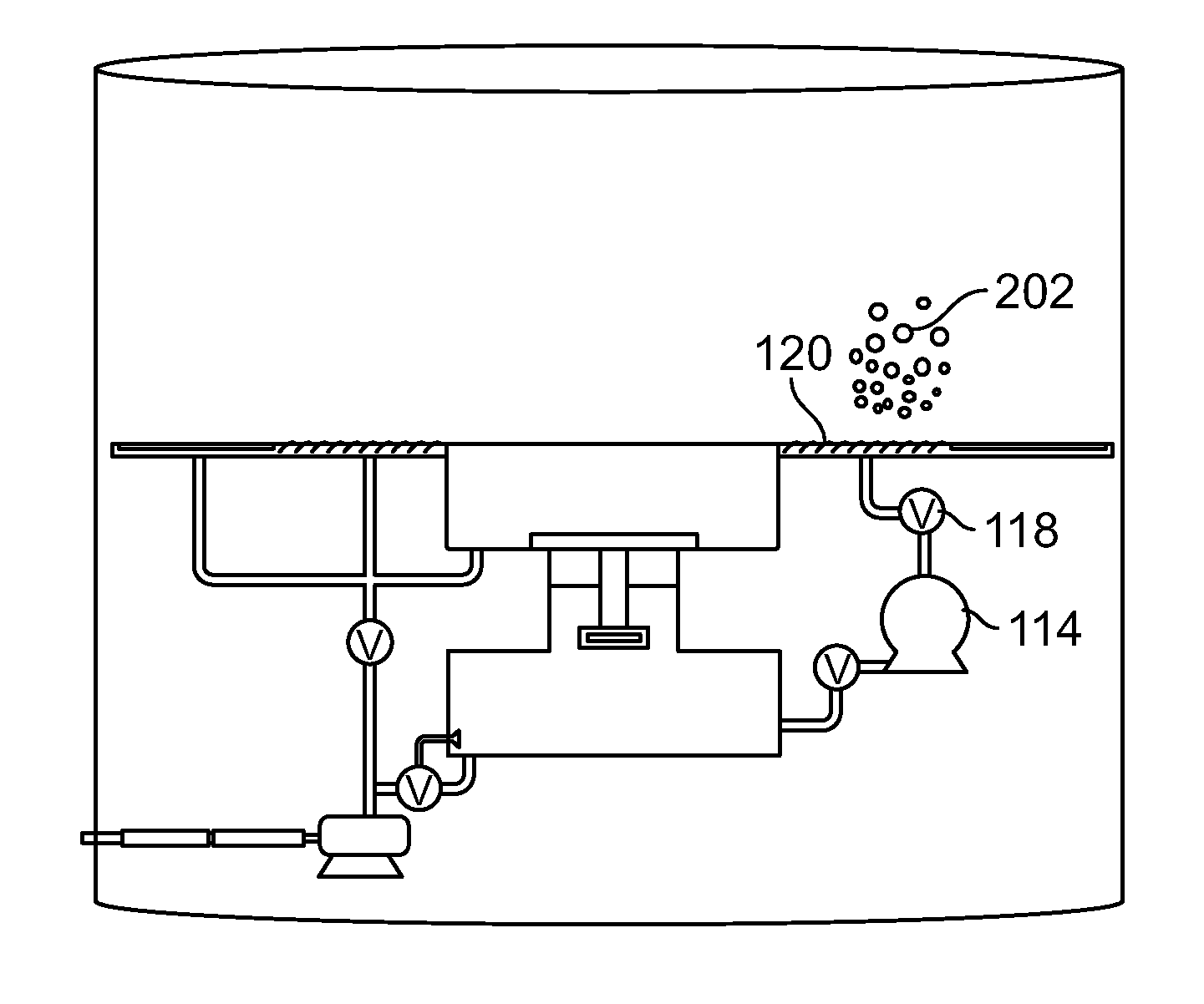

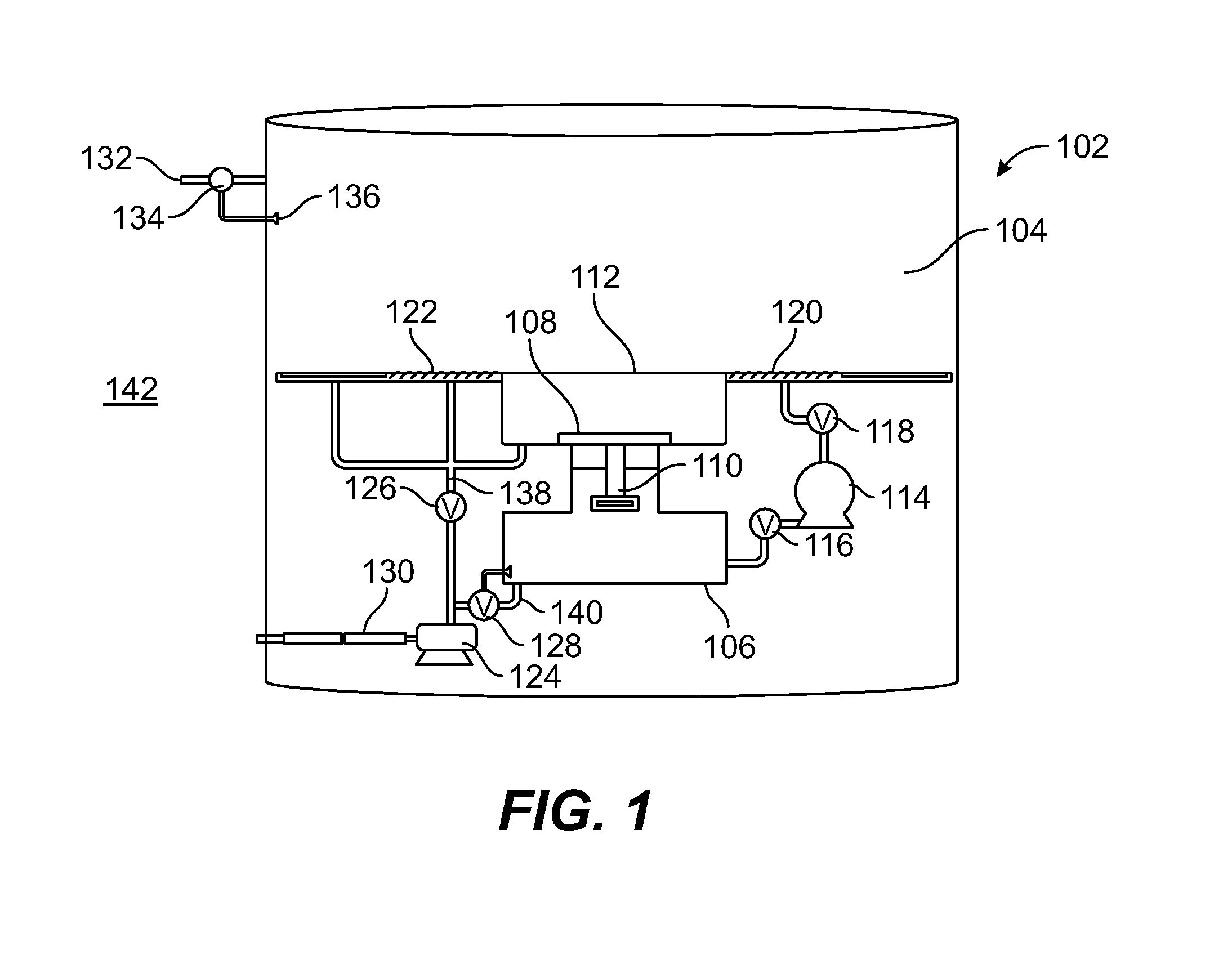

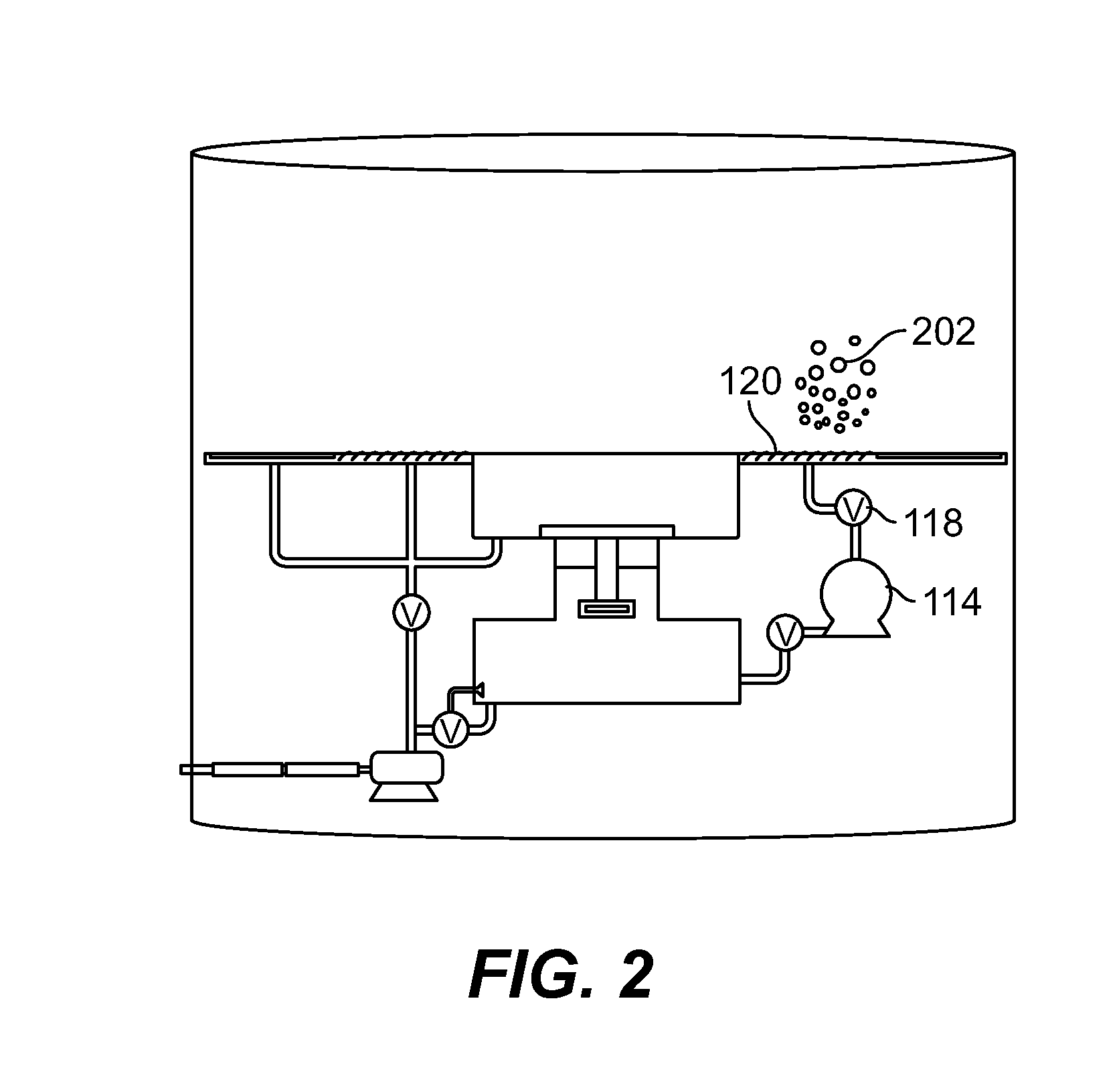

[0025]FIG. 1 depicts an embodiment of the clothes washer 102, wherein a washing chamber 104 may be filled from a water source 132 when valve 134 is opened. In the depicted embodiment, washer 102 will fill with water to a predetermined level controlled by electronic water level sensor 136, which signals valve 134 to close when water has reached the predetermined level for clothes washer operation. As will be appreciated by those of skill in the art, a number of other means may be employed for filling the washing chamber with water to a predetermined level. Such means include a float valve such as commonly used in flush toilets. Alternatively, such means may comprise a timed solenoid valve, which simply opens for a fixed period of time and then closes. Yet further, such means for filling with water may comprise a valve that is manually operated based on information displayed on a fill gauge. Those of skill in the art will realize that the present invention contemplates any and all suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com