Expansion Valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

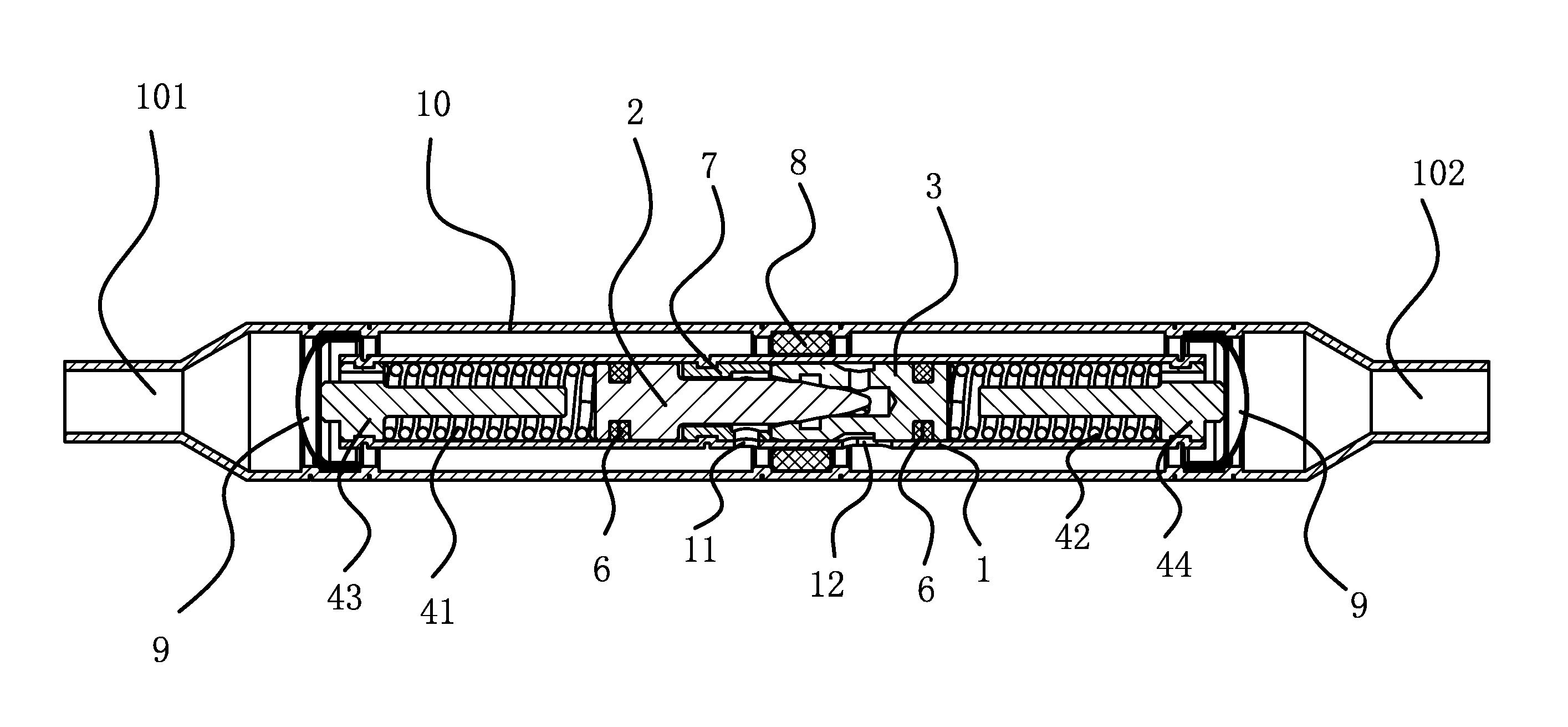

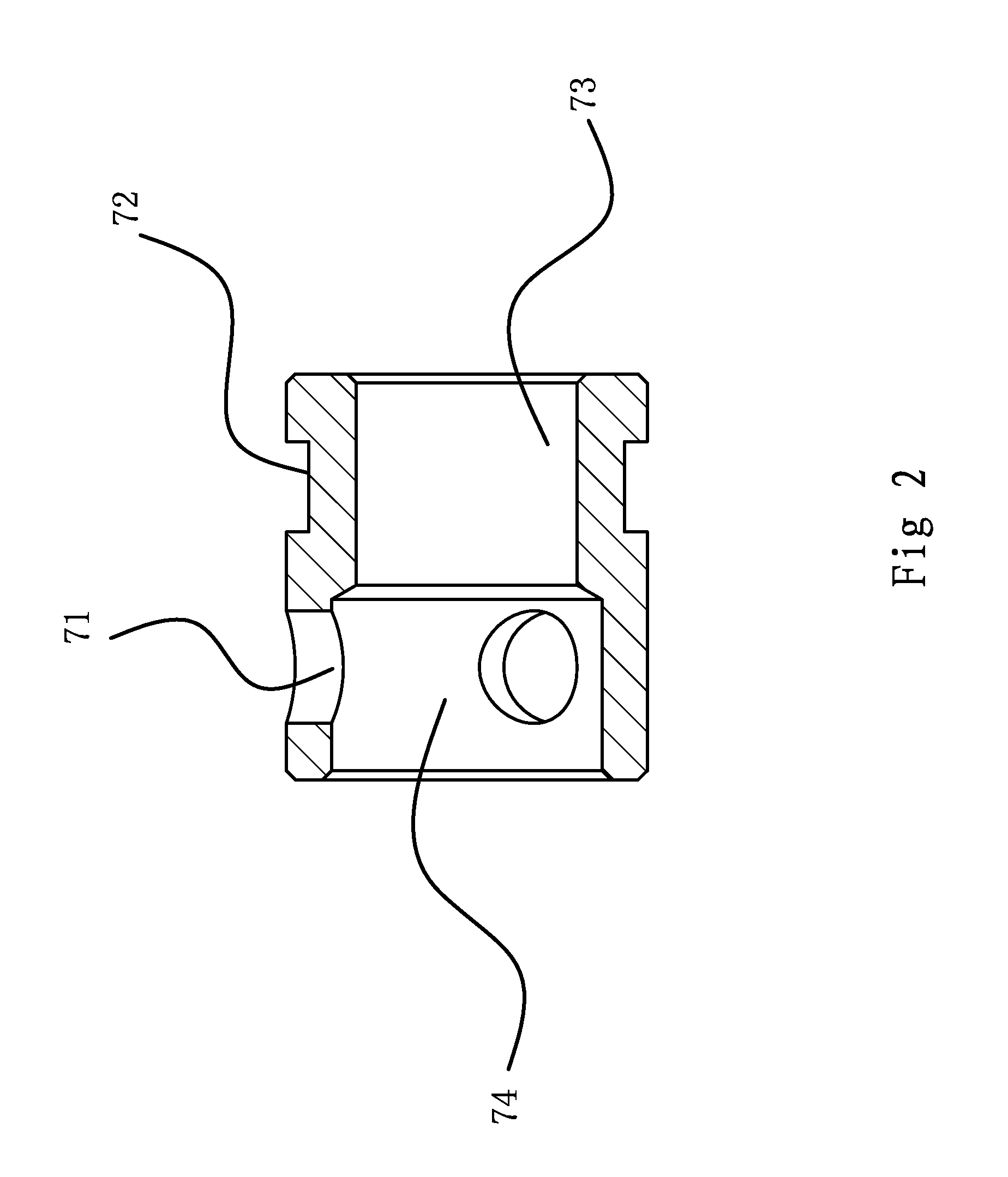

[0042]As shown in FIG. 1, An expansion valve comprises a housing (10) with an inlet end (101) and an outlet end (102), a cylindrical valve body (1) with an inner cavity fixed inside the housing (10), on the side of the valve body (1) wall there are an inlet (11) and an outlet (12) connecting the inner cavity and housing (10), and a spacer sleeve (8) between the housing (10) and valve body (1) that separates the inlet (11) and outlet (12). In the inner cavity, there is a matched set of the first valve core (2) and the second valve core (3) sliding along its inside. A retaining ring (7) is fixed to the mid-section of the inner cavity between the two valve cores. At both ends of the inner cavity there are spring assemblies pressing the first valve core (2) and the second valve core (3) towards the retaining ring (7). A damping structure is provided between the first valve core (2) and the second valve core (3).

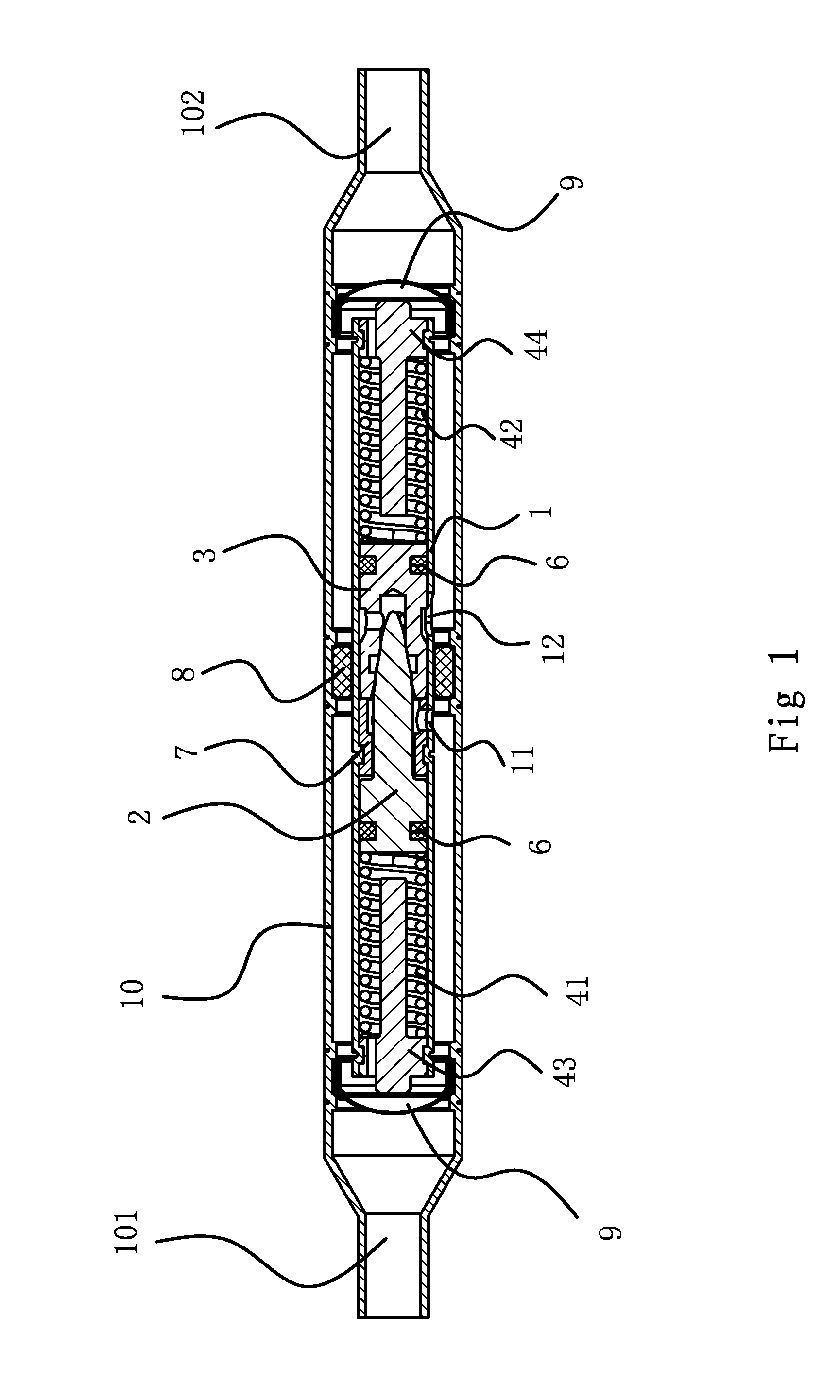

[0043]Specifically, as shown in FIGS. 1 through 5, the retaining ring (7) co...

second embodiment

[0053]The principle and structure of this embodiment are substantially similar to that of the first preferred embodiment. As shown in FIG. 6, the difference from the first preferred embodiment is that a flow path for small flow is added. Its structure comprises a vent (34) on the second valve core (3), connecting the outside of the valve body (1) and the relief groove (33). Capillary tubes are installed in the trough hole (34). The flow rate of the vent (34) can be changed by installing capillary tubes.

third embodiment

[0054]The principle and structure of this embodiment are substantially similar to that of the second preferred embodiment. As shown in FIG. 7, the difference from the second preferred embodiment is in the flow path for small flow. Its structure comprises a diversion slot (27) on the first valve core (2), connecting the relief groove (33) and the front cylinder bore (36).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com