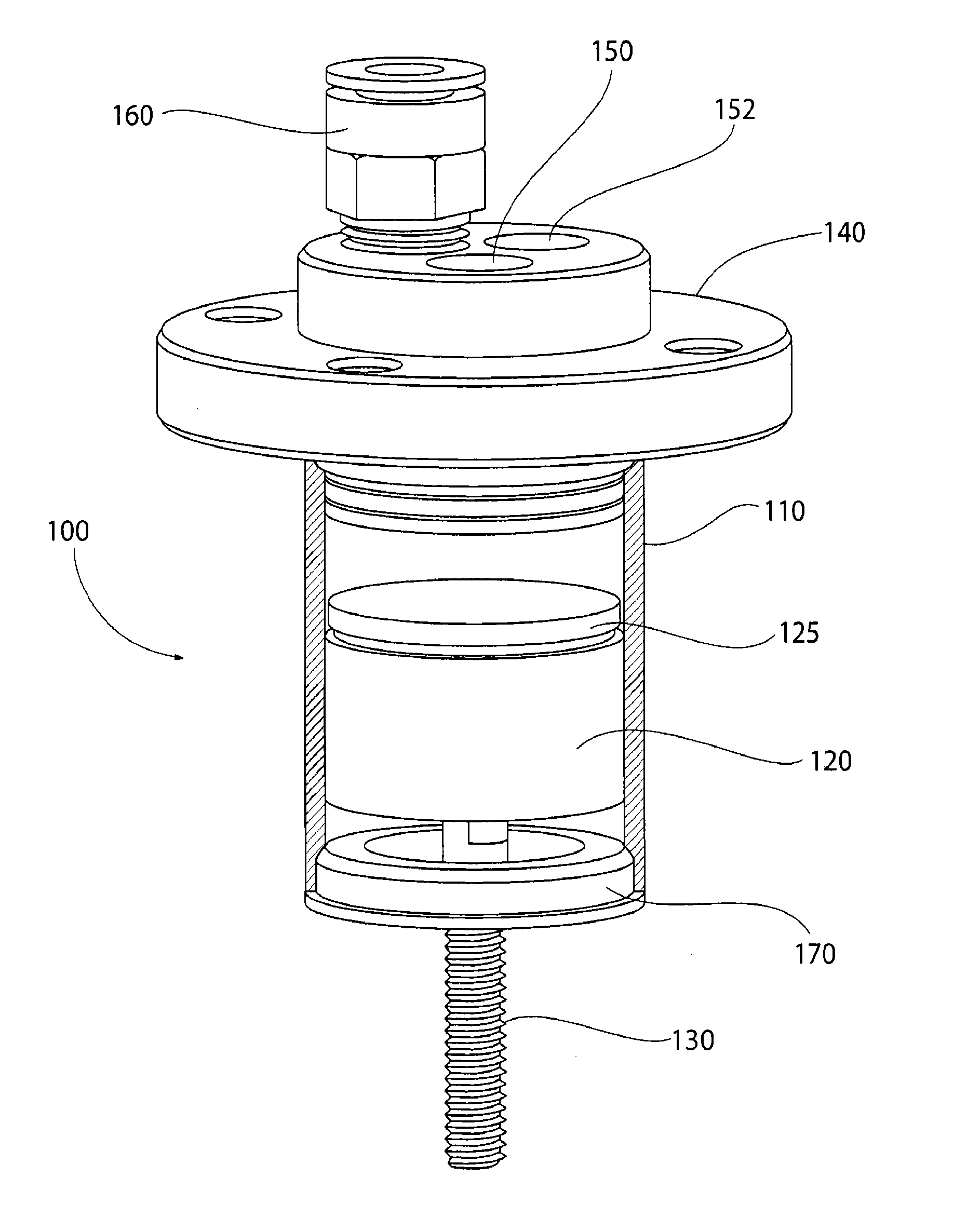

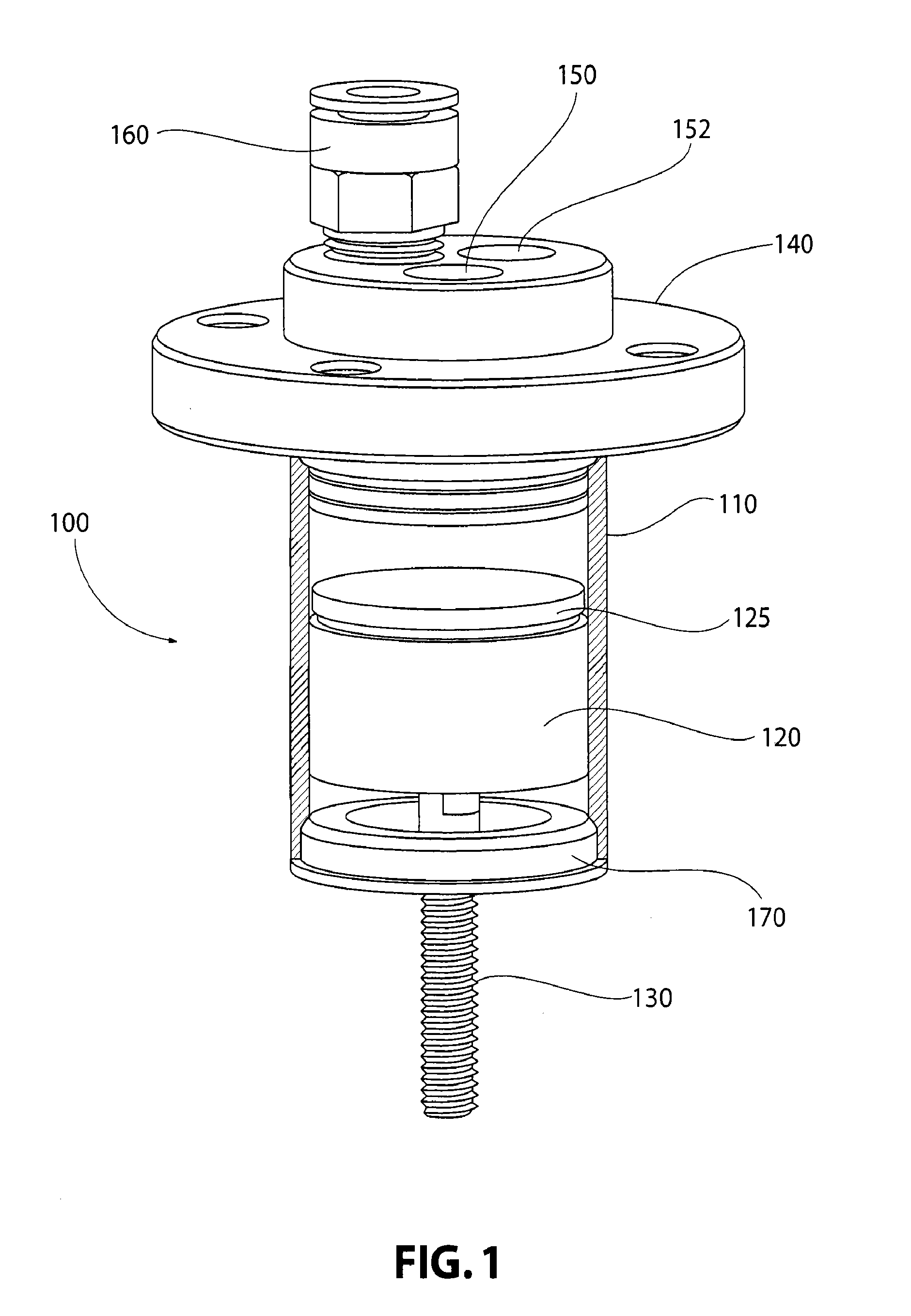

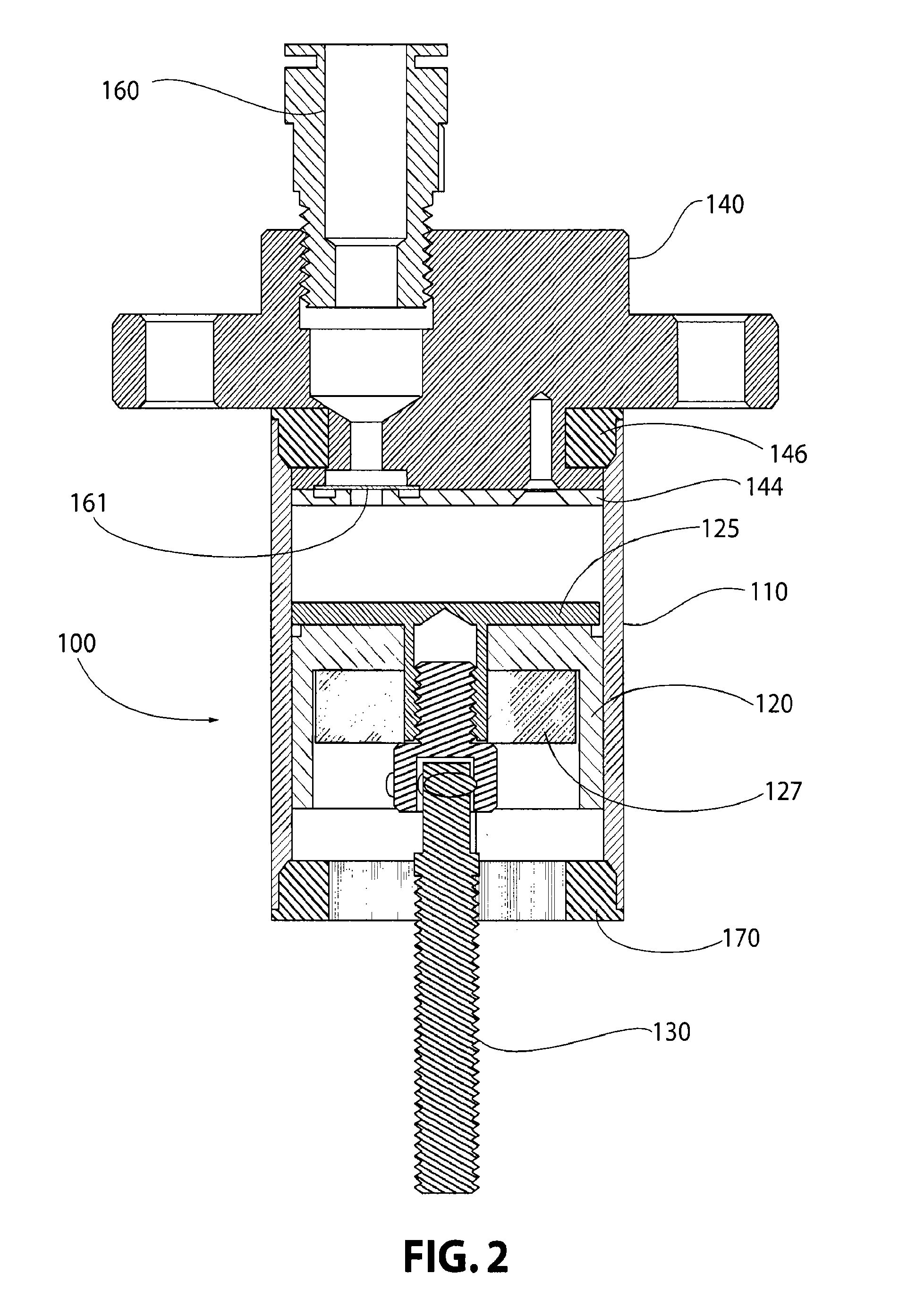

Lubricant-Free Compressor Having a Graphite Piston in a Glass Cylinder

a graphite piston, graphite technology, applied in the direction of piston pumps, positive displacement liquid engines, liquid fuel engines, etc., can solve the problem that compressors cannot operate without lubrican

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]While the following describes embodiments of this invention, it is understood that this description is to be considered only as illustrative of the principles of the invention and is not to be limitative thereof, as numerous other variations, all within the scope of the invention, will readily occur to others.

[0030]The term “adapted” shall mean sized, shaped, configured, dimensioned, oriented and arranged as appropriate. Herein, it will also be understood that in the figures, different embodiments may comprise the same or similar components. Where the same components are used in different embodiments, the same reference number may be used. Where components in different embodiments have a comparable structure, but are not necessarily common or identical parts, a similar number is used, but with a differing initial first digit, but common second and third digits. For example, and without limitation, cylinder heads 140, 240, 540, and 640 are examples of similar structures adapted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com