Electric blower

a blower and electric technology, applied in the direction of liquid fuel engines, mechanical equipment, machines/engines, etc., can solve the problems of difficult to manage the clearance between the tip of the impeller and the cover at a predetermined level, affecting the performance, and difficult to manage the tolerance between, so as to facilitate the assembly of the impeller and avoid the effect of the separation phenomenon of the impeller and the effect of easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

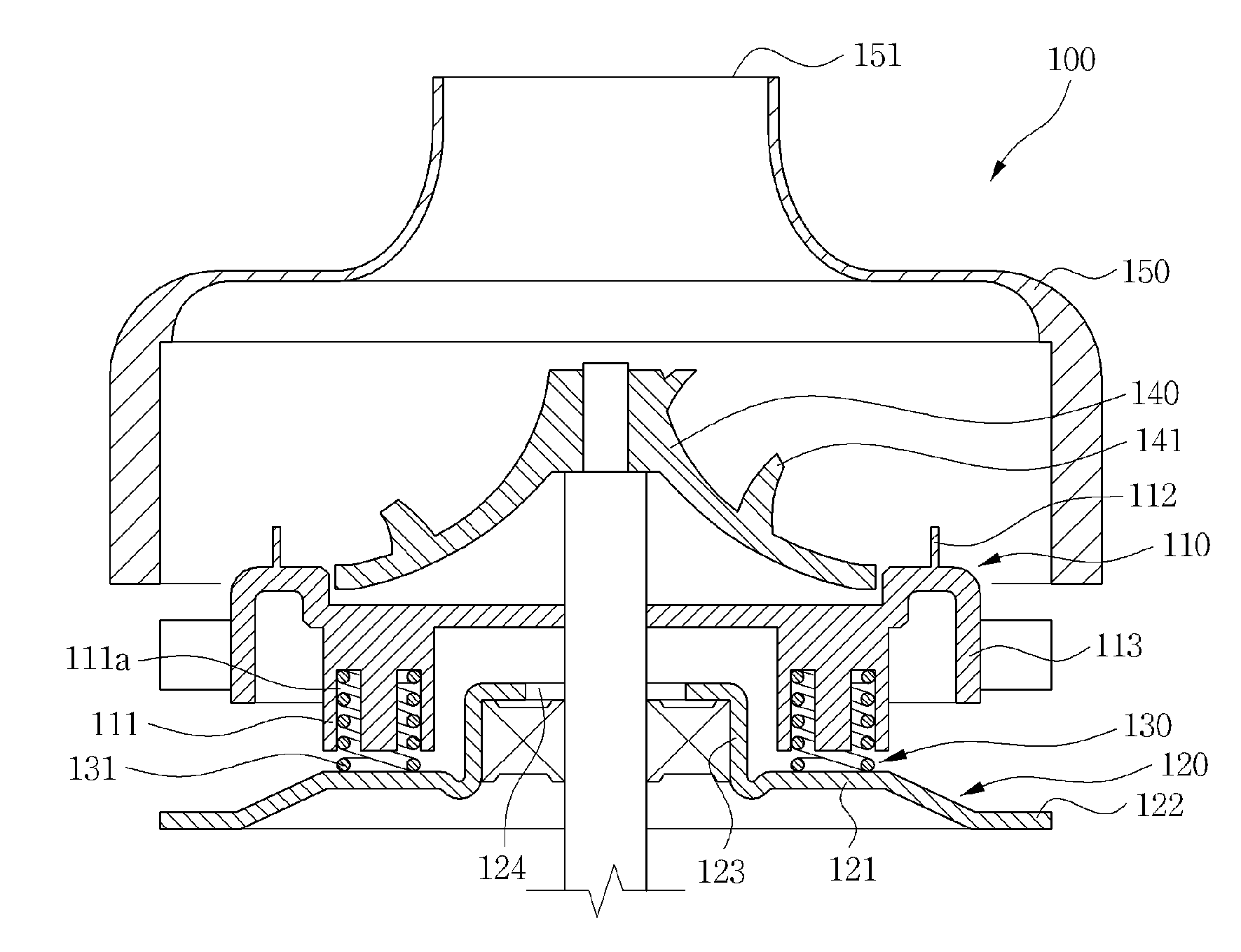

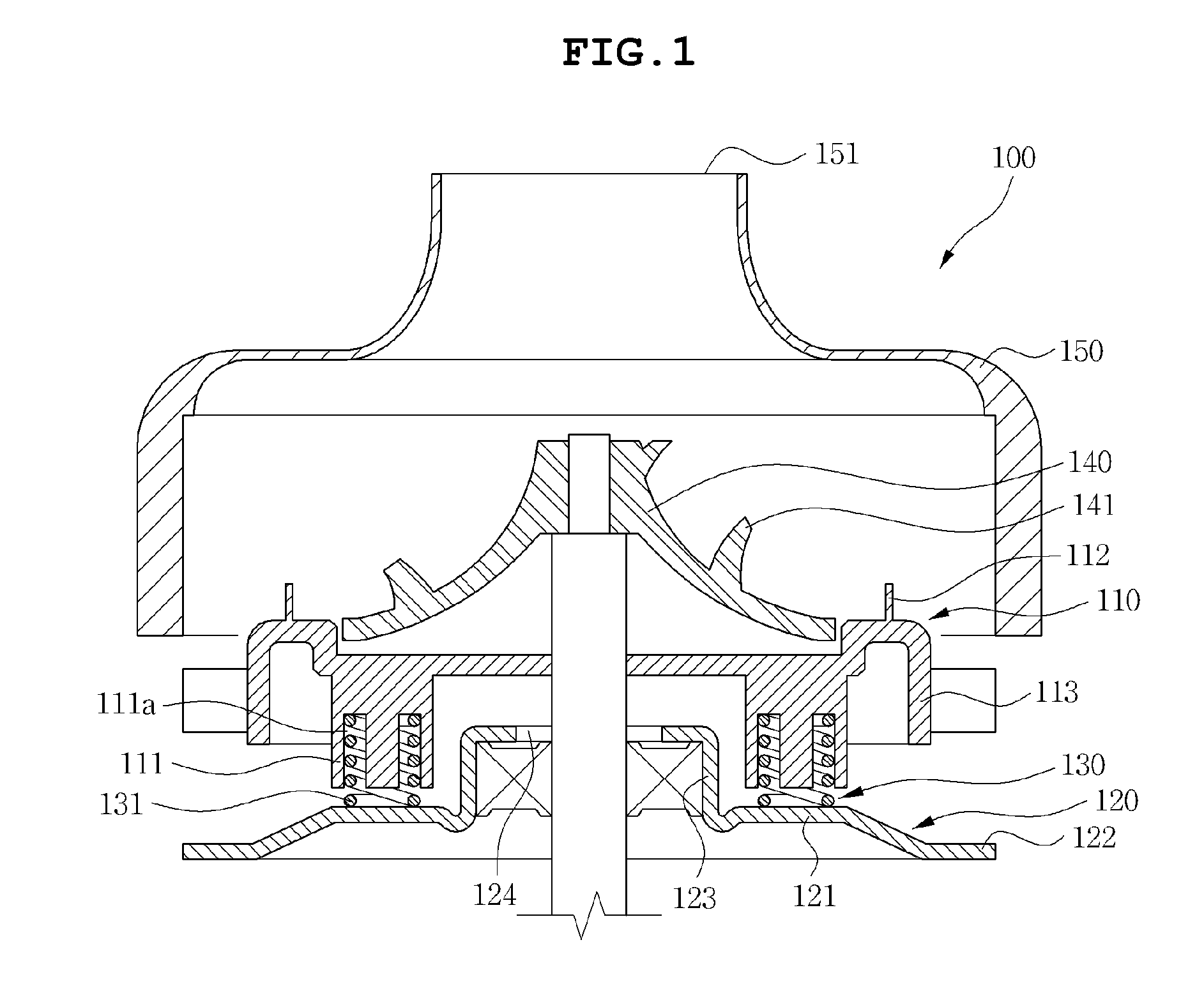

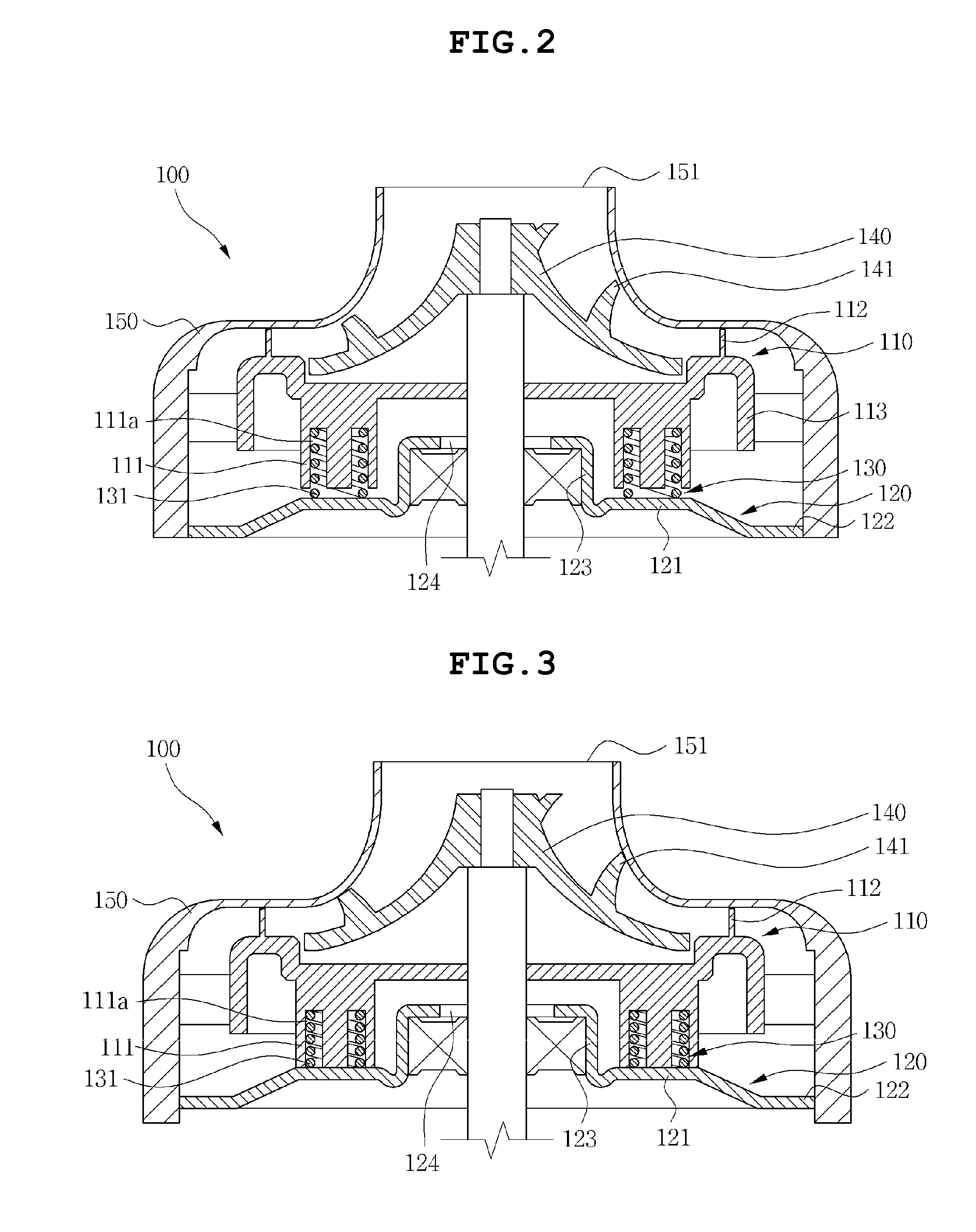

[0029]As illustrated in FIGS. 1 to 3, an electric blower 100, according to a first embodiment of the invention, includes a diffuser 110, a front 120, and an elastic body 130. According to at least one embodiment, the elastic body 130 includes a spring 131. The electric blower has a structure in which the diffuser 110 is disposed at a lower portion in a shaft direction of the impeller 140 in the drawings to guide introduced air and the front 120 is disposed at a lower portion of the diffuser 110 in a shaft direction to support the diffuser 110, and the elastic body 130 is mounted between the front 120 and the diffuser 110.

[0030]According to at least one embodiment, the impeller 140 is provided so that upper ends of wings 141 for introduction of air, for example, are exposed to the outside and thus an inlet 151 into which external air is introduced is received in the cover 150, which is formed at a central portion of the electric blower 100. According to at least one embodiment, the e...

second embodiment

[0040]As illustrated in FIGS. 4 and 5, an electric blower 200, according to a second embodiment of the invention, includes an impeller 240, a shaft 263 with which the impeller 240 is assembled in a shaft direction, and a nut 201 which fastens the shaft 263 with the impeller 240 to assemble the shaft 263 and the impeller 240. In addition, the electric blower 200 further includes a diffuser 210 in which the impeller 240 is disposed at one side in the shaft direction thereof, a cover seating part 212 contacting an inner side of the cover 250 is provided, and a guide part 213 guiding air introduced through an inlet 251 of the cover 250 is formed at an edge of a circumference thereof, a front 220, and a spring 231 mounted in a receiving space 211 a formed at the support part 211 of the diffuser 210.

[0041]According to at least one embodiment, a configuration of the diffuser 210, the front 220, the spring 231, and the cover 250 and a coupling relationship and an acting effect of the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com