Advantageously recyclable environment-friendly thermal insulation box

a technology of thermal insulation box and environmentally friendly, which is applied in the field of environmentally friendly thermal insulation box, can solve the problems of poor compatibility of epu material for the insulation layer with plastic products made of polyolefin polymers, stale or even rotten foodstuffs, etc., and achieves the effect of reducing the heat transfer efficiency of the insulation layer and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will now be described with some preferred embodiments thereof and with reference to the accompanying drawings. For the purpose of easy to understand, elements that are the same in the preferred embodiments are denoted by the same reference numerals.

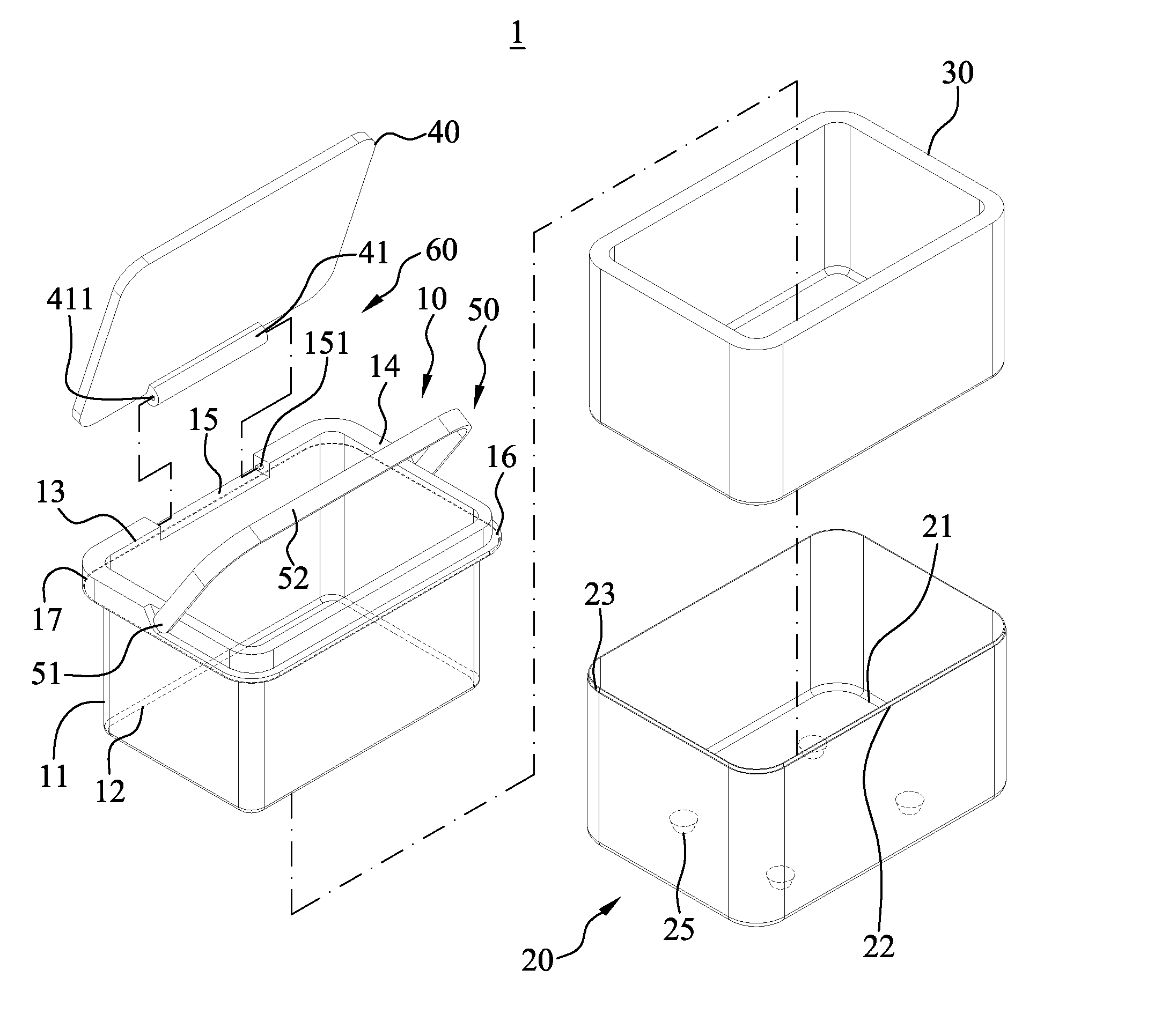

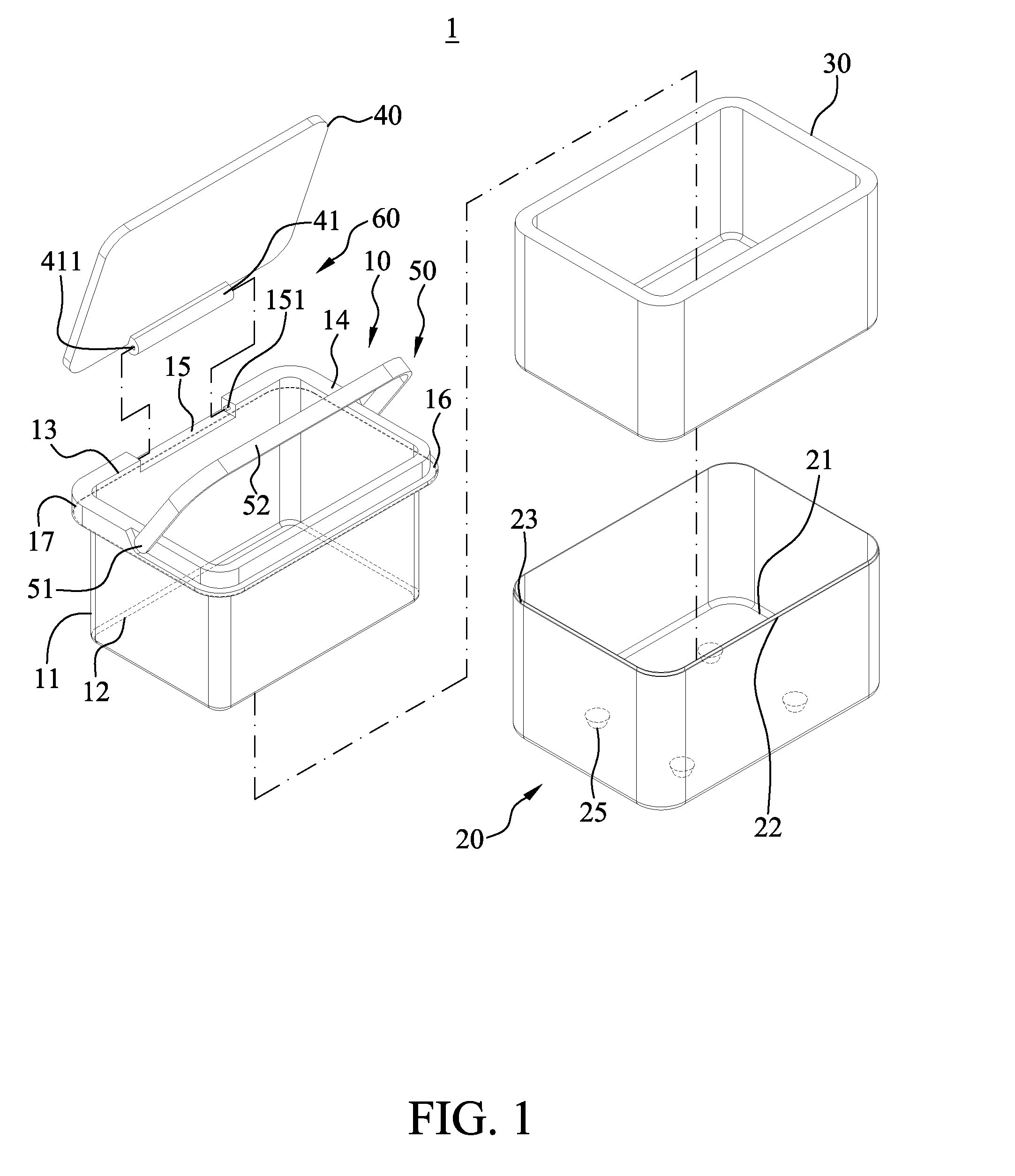

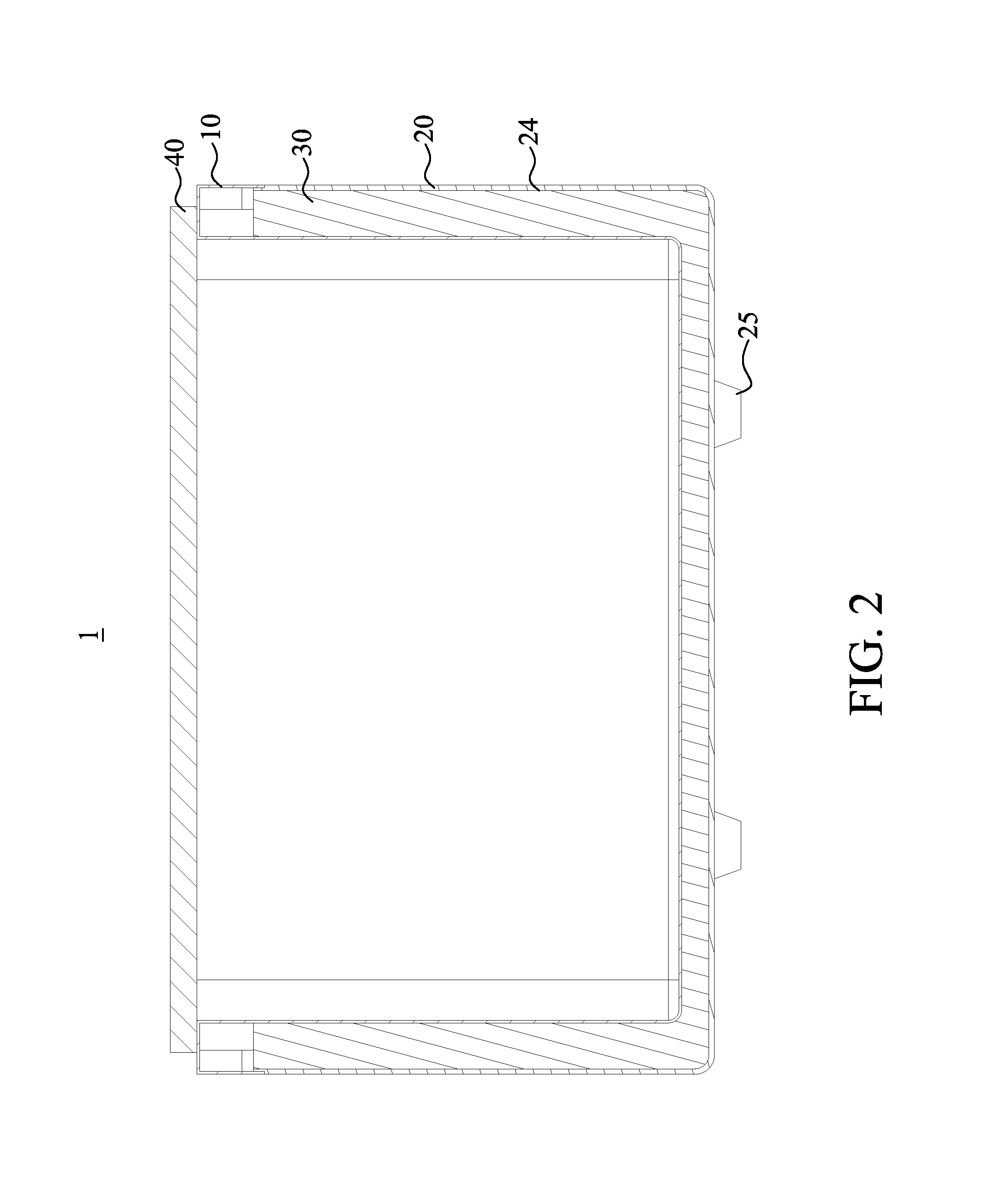

[0023]Please refer to FIGS. 1 and 2, which are exploded perspective and assembled sectional views, respectively, of an advantageously recyclable environment-friendly thermal insulation box according to a first preferred embodiment of the present invention. For the purpose of conciseness and clarity, the present invention is also briefly referred to as the thermal insulation box herein and generally denoted by reference numeral 1. As shown, in the first preferred embodiment, the thermal insulation box 1 includes an inner box 10, an outer box 20, an insulation layer 30, a cover 40, and a handle 50. The inner box 10 is made of a polypropylene (PP) material and includes a peripheral wall 11, a sealed bottom 12 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com