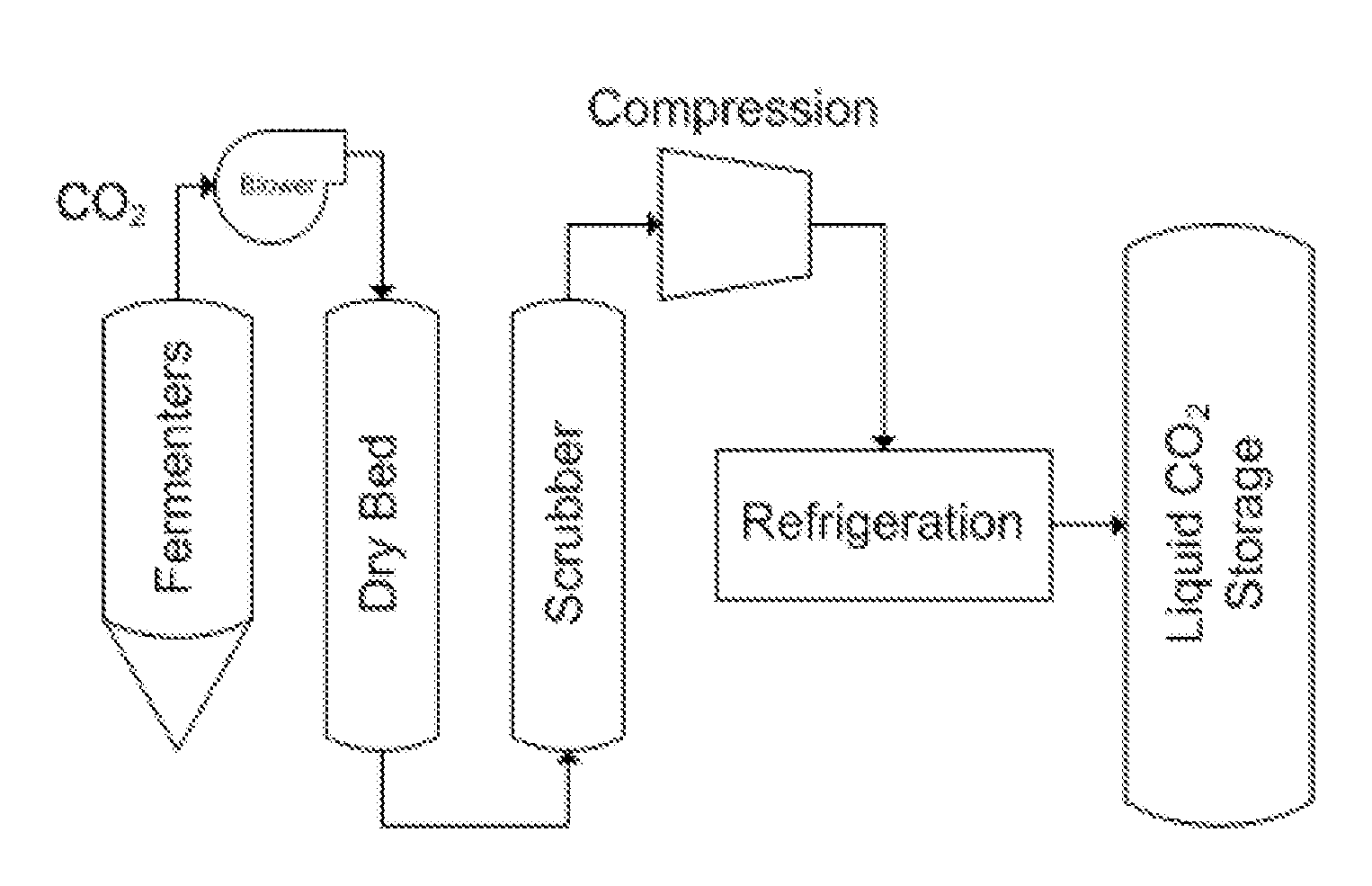

Systems and methods for recovering carbon dioxide from industrially relevant waste streams, especially ethanol fermentation processes, for application in food and beverage production

a technology of ethanol fermentation and waste stream, which is applied in the field of systems and methods for recovering carbon dioxide from industrially relevant waste stream, especially ethanol fermentation process, for application in food and beverage production, can solve the problems of large footprint, large scale, and high cost of system installation, and achieves minimal workload for brewery cellar operators , the effect of easy relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The following description is merely exemplary in nature and is in no way intended to limit the scope of the present disclosure, application, or uses.

DEFINITIONS

[0052]The following terms of art shall have the below ascribed meanings throughout this specification, unless otherwise stated.

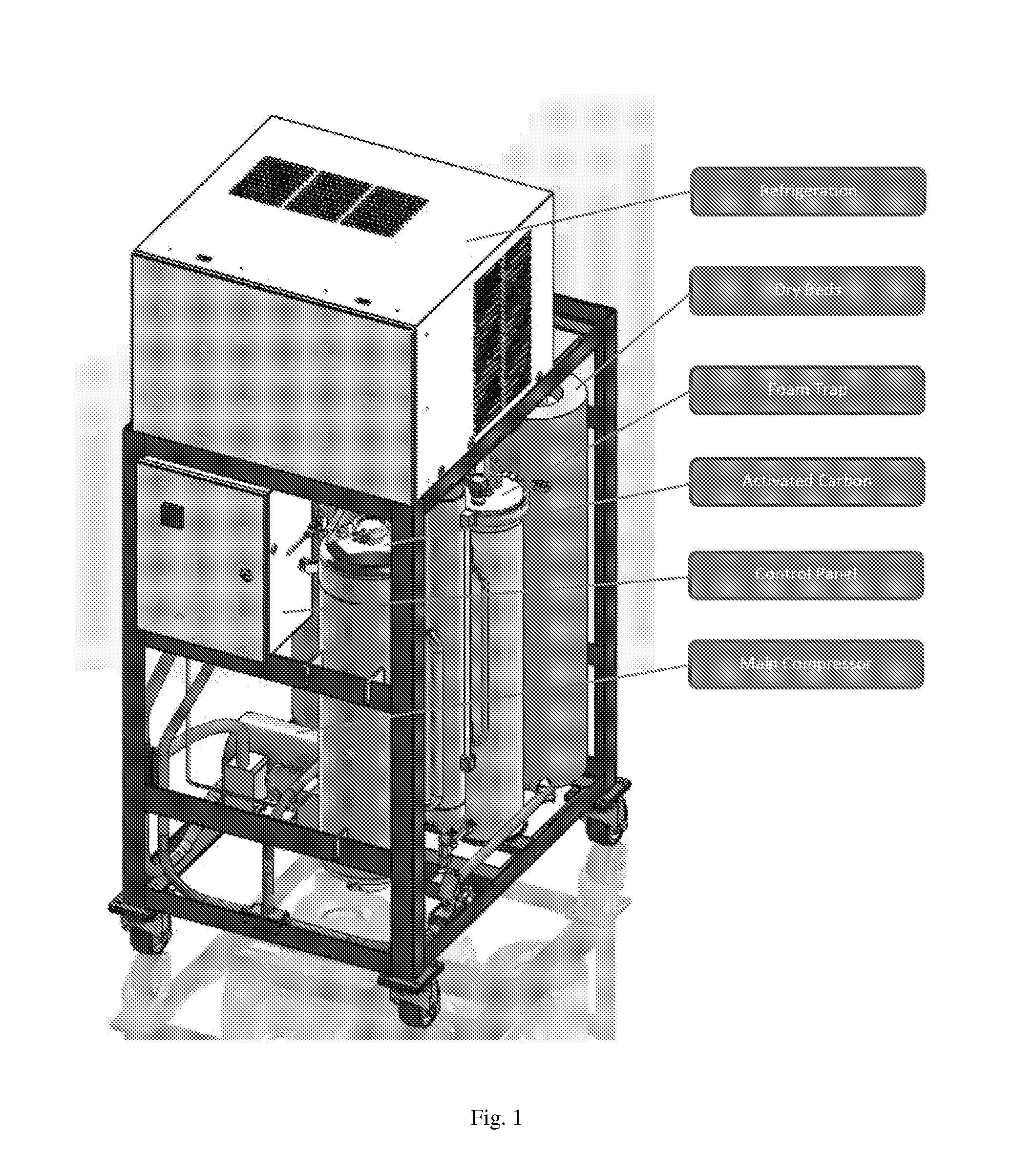

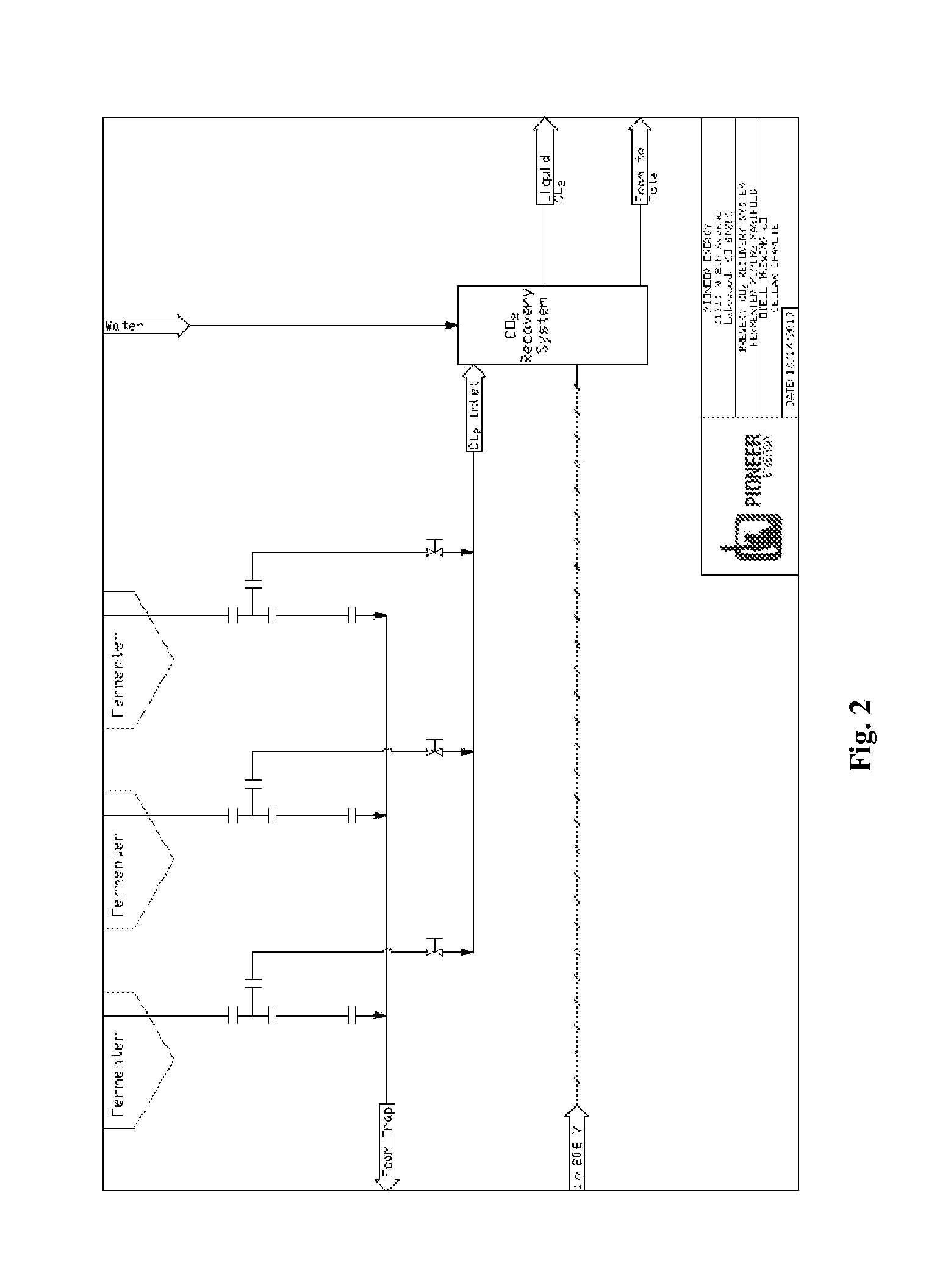

[0053]Throughout this disclosure a CO2 recovery “system,”“unit,” or “apparatus,” or any reference to a single commercially viable module, will refer to an apparatus module that can process a given number of pounds (kilograms) of carbon dioxide per day. Volumetric flow rates of trace compounds including air, humidity, ethanol vapor, trace organics including higher alcohols, aldehydes, ethers, and esters are considered negligible. Multiple modules can be combined for higher gas flow rates and to address the cyclic behavior of manifolded fermenter effluent flow rates. Product flow estimates and sinusoidal characteristics are based on direct flow measurement of CO2 effluent from a batch fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com