Radial or mixed-flow compressor diffuser having vanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

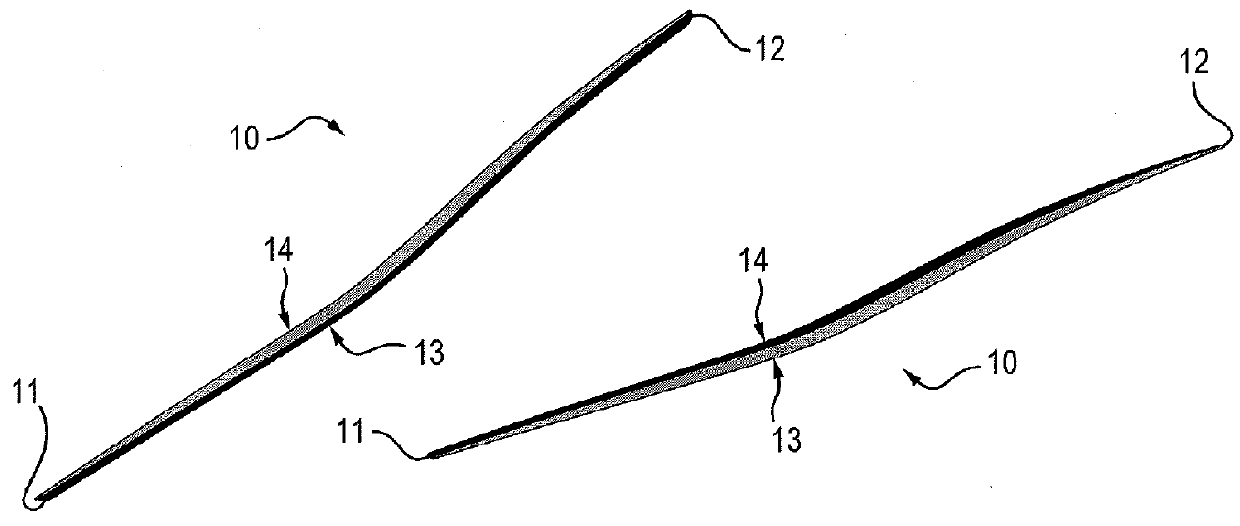

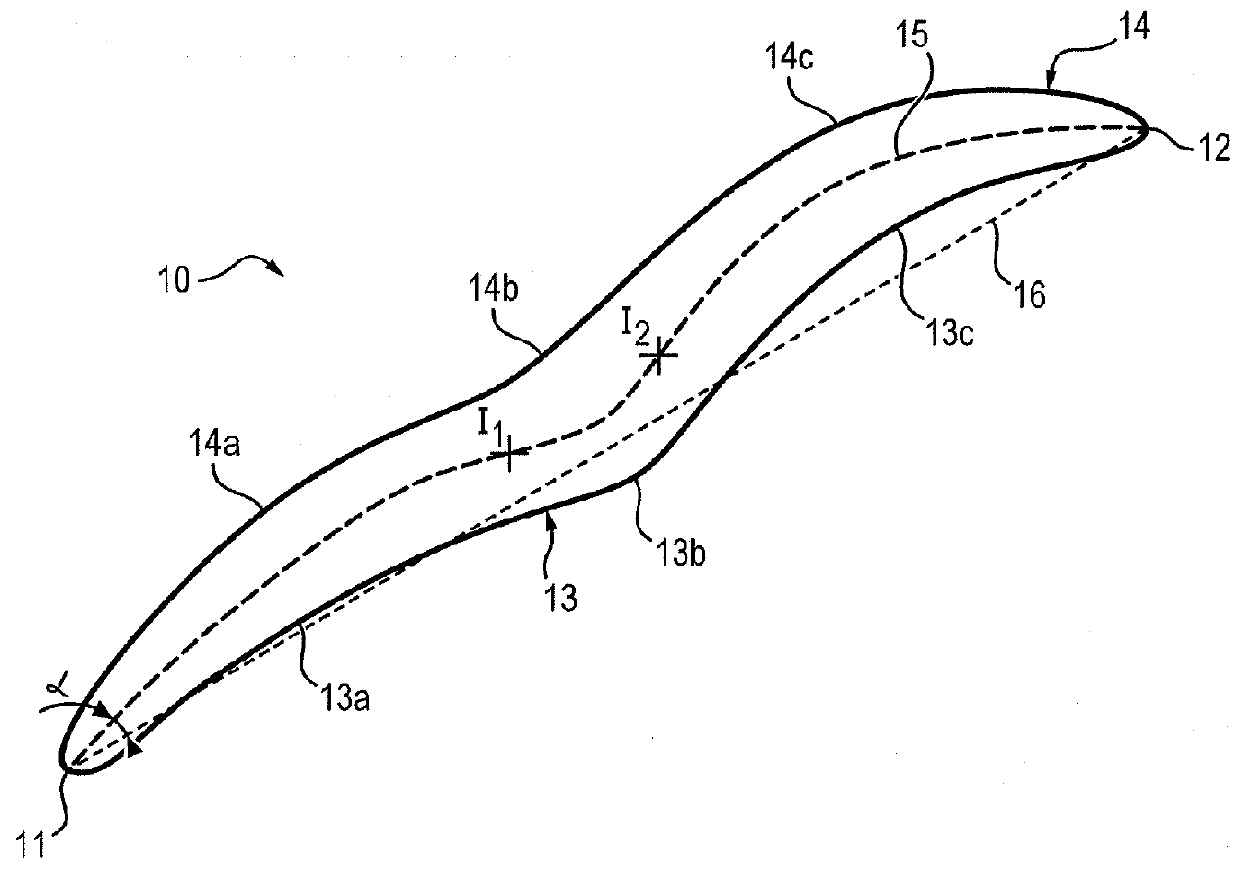

[0021]A radial diffuser according to the present invention is in particular designed to be used with a radial or mixed-flow compressor 2.

[0022]FIG. 4 is a partial section of an engine 1 comprising a radial compressor 2. A gas flow F is first aspirated into an air entry channel, then compressed between the blades 3a of a wheel 3 of the radial compressor 2 and its casing. The compressor 2 has axial symmetry about an axis X. The compressed gas flow F then exits radially from the wheel 3. If the compressor 2 were of mixed-flow type, the gas flow would exit inclined at a nonzero angle with respect to a direction radial to axis X.

[0023]The compressed air exits the wheel 3 radially while still having angular momentum, and passes into diffuser 5. The role of the diffuser is to convert part of the kinetic energy of the gases coming from the compressor 2 into static pressure by slowing the speed of the gases, and to straighten the flow exiting the wheel 3. It includes for this purpose a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com