High moisture transferable textile sheet

a textile sheet and high moisture technology, applied in the direction of synthetic resin layered products, bed linen, handkerchiefs, etc., can solve the problems of difficult fabric manufacturing, fabric thinness, and limited use of sport clothing, and achieve the effect of rapid drying speed and excellent absorbing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

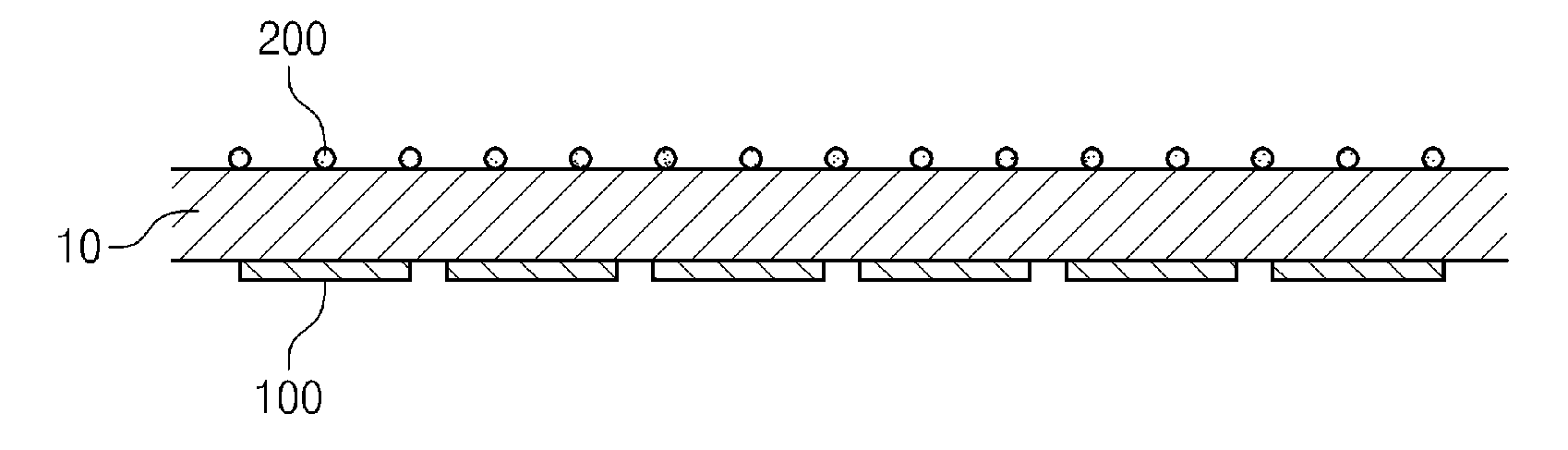

Image

Examples

example

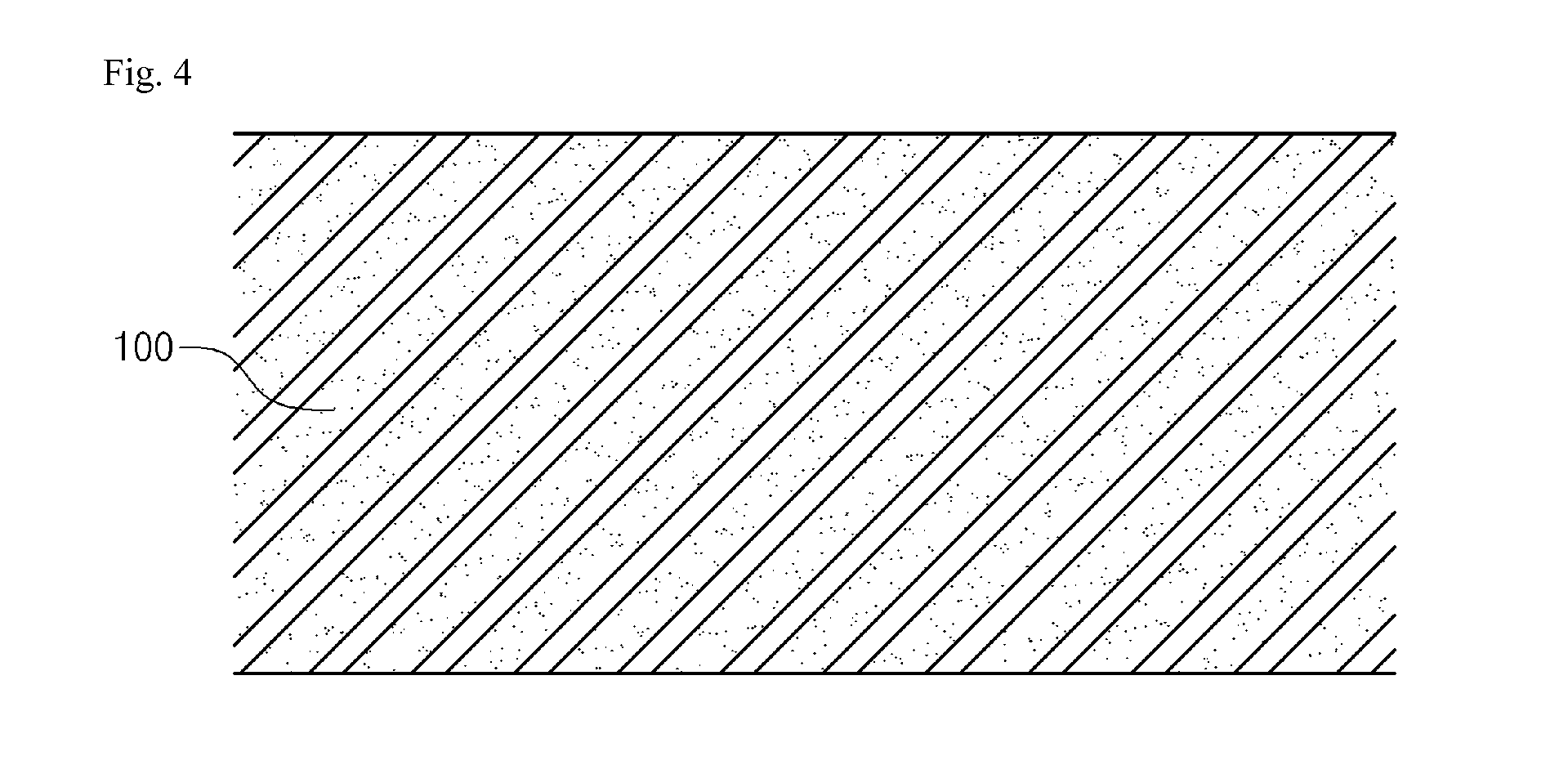

[0052]A high hygroscopicity polymer having a particle size of 70 μm and a polyurethane-based binder were coated in weight ratio of 1:2 on one side of polyester fabric. A water-repellenting composition mixed with the polyurethane-based binder and silicon water-repellenting agent in weight ratio of 4:1 was coated on the other side of the fabric to form a water-repellenting layer.

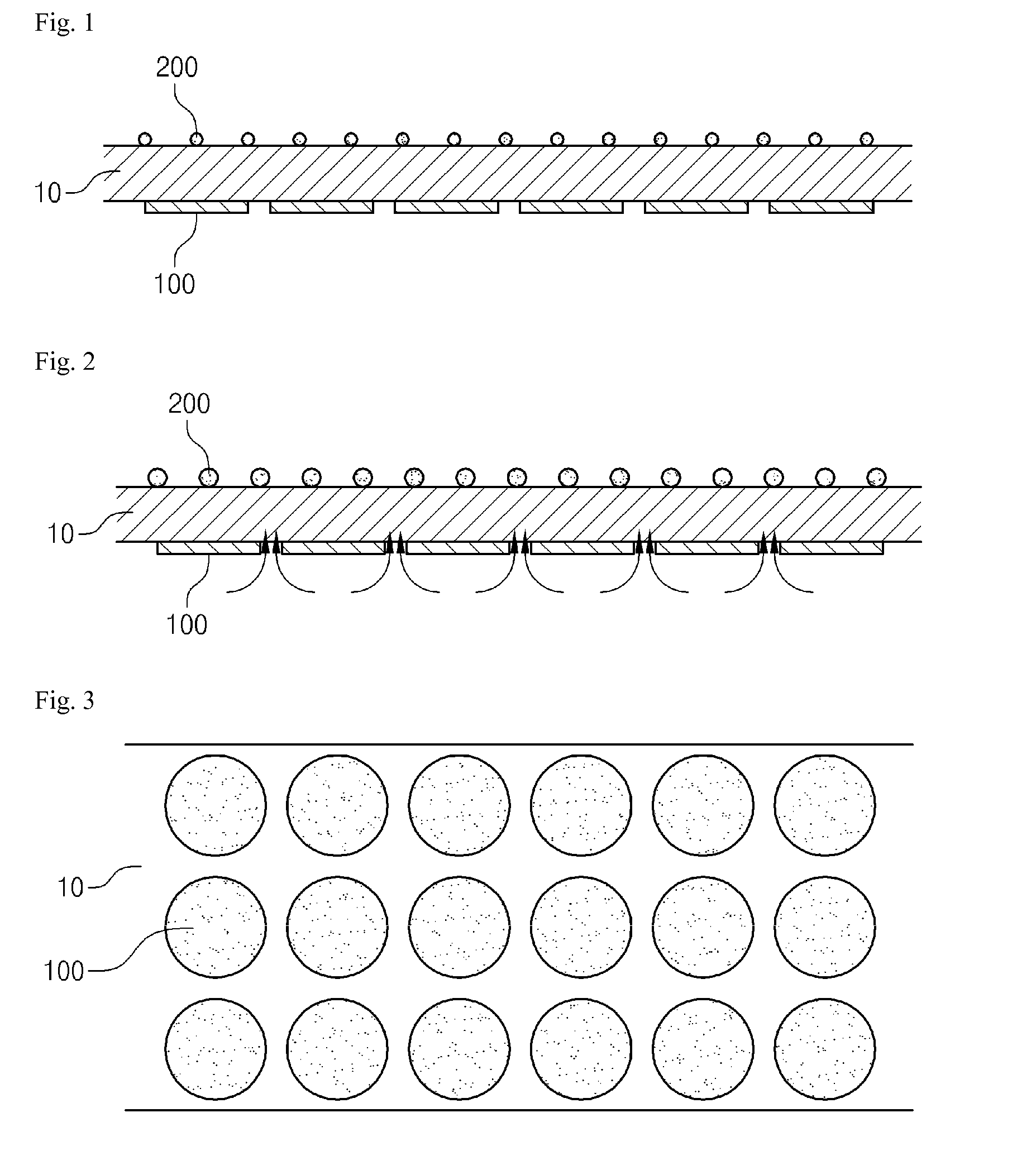

[0053]The water-repellenting layer was coated with water-repellenting composition as shown in FIG. 3, and a gap without the water-repellenting composition in the water-repellenting layer was formed having a size of 0.2 mm to 0.8 mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com