Shelving structure

a technology of shelving structure and shelving plate, which is applied in the direction of display hangers, dismountable cabinets, cabinets, etc., can solve the problems of high defect rate and higher manufacture cost, and achieve the effect of easy manufacturing and better stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

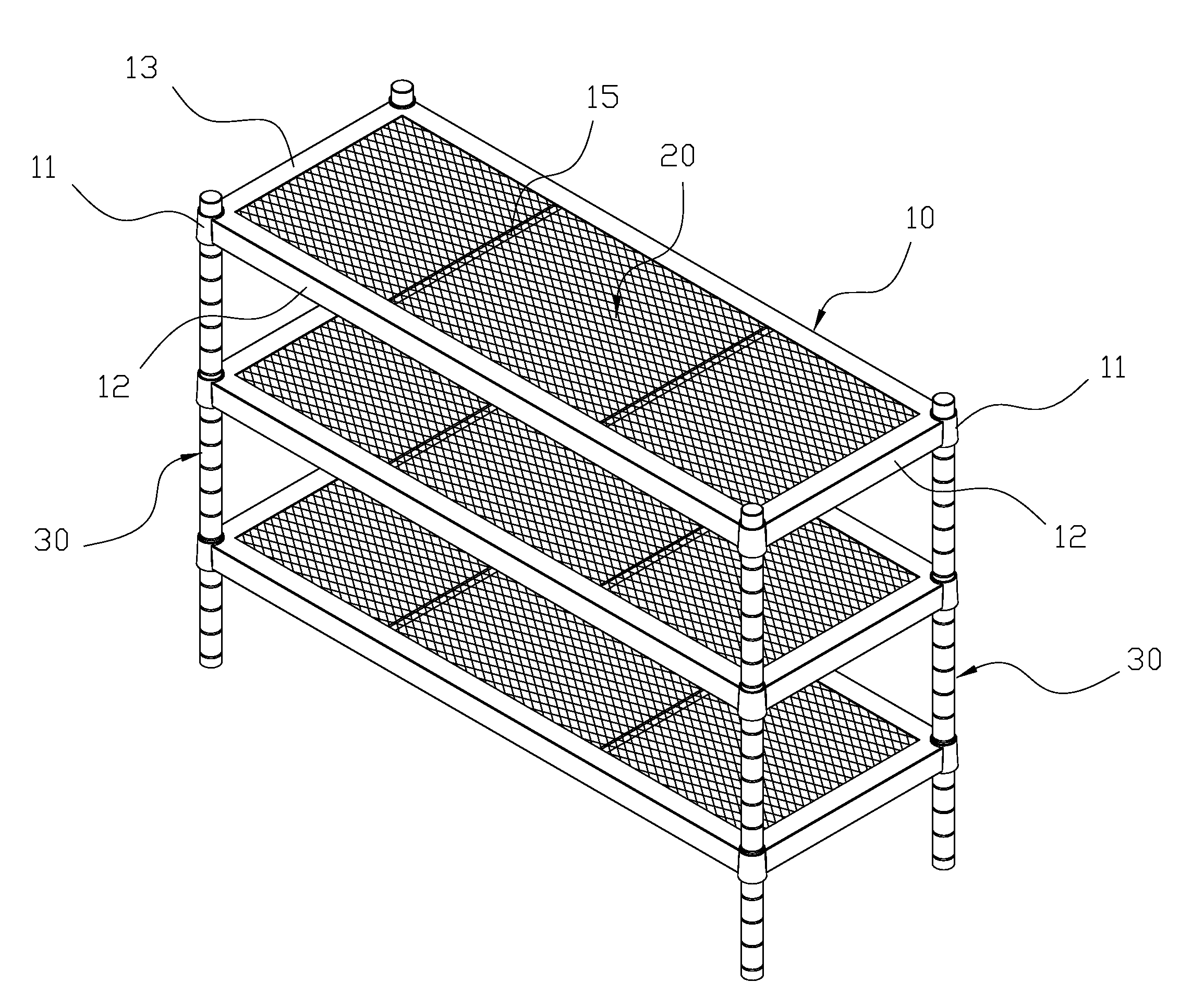

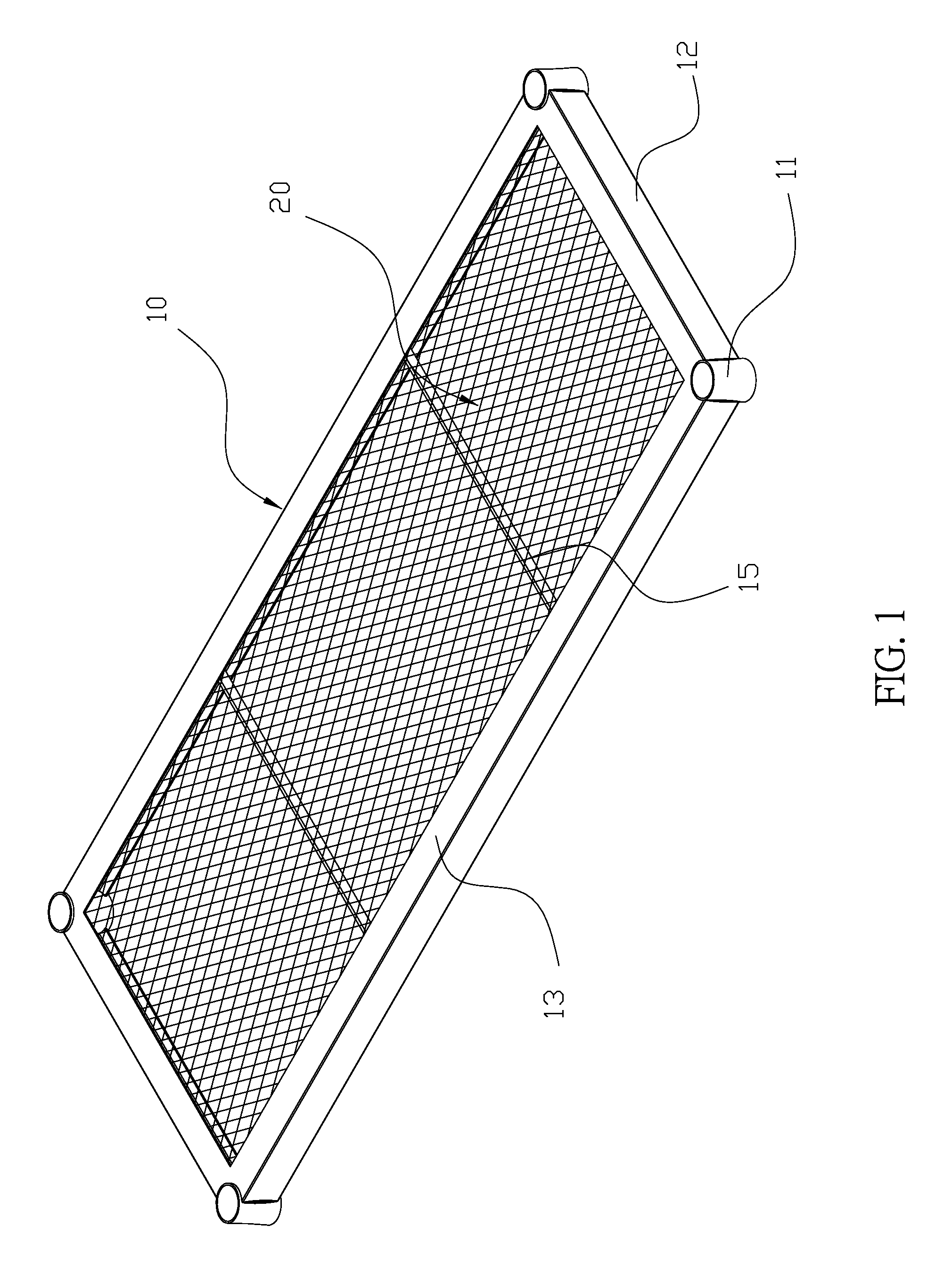

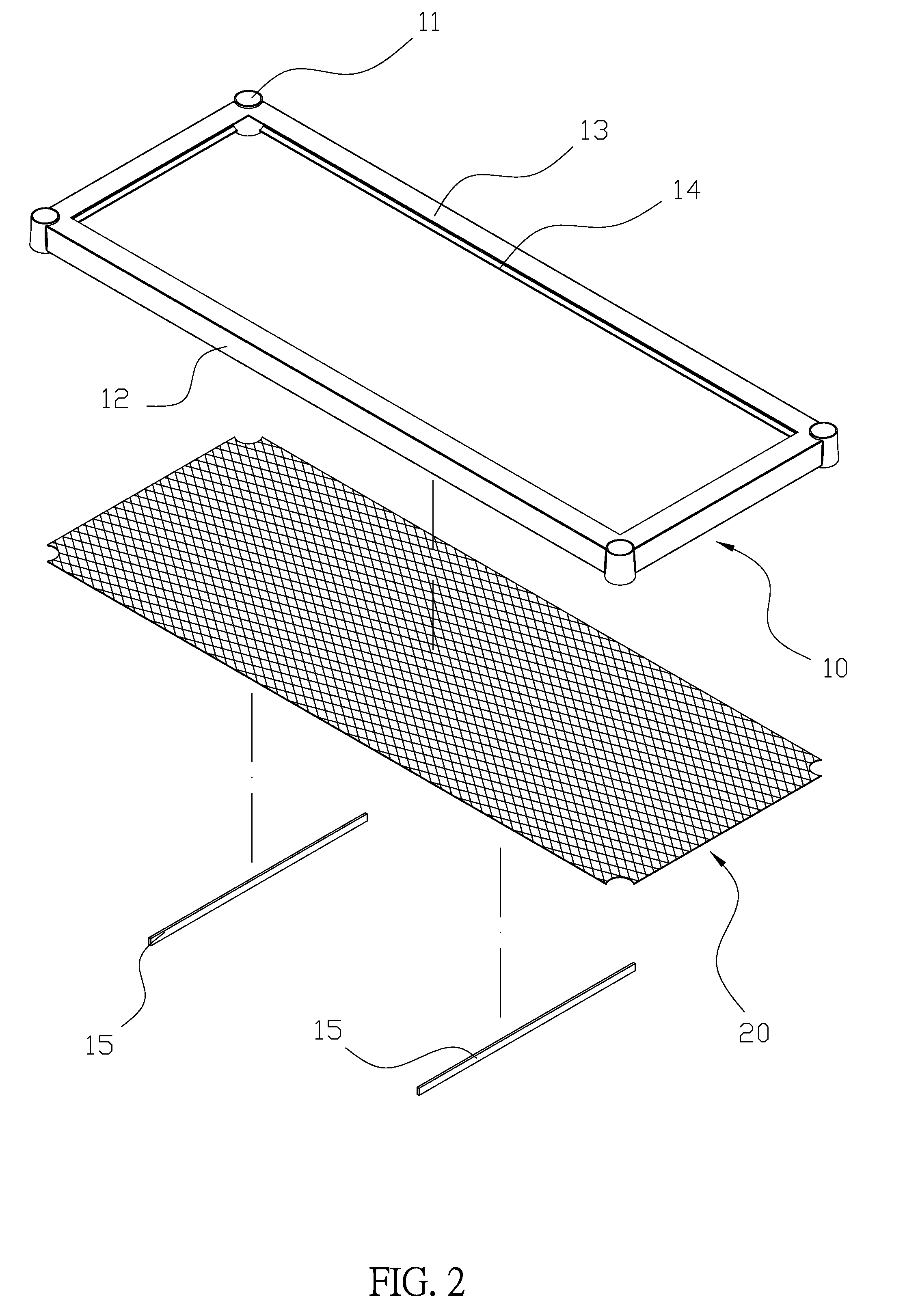

[0016]Please refer to FIGS. 1, 2 and 3. A shelving structure comprises a frame member 10 and a woven body 20. The frame member 10 has a rectangular shape and a respective connecting pipe 11 disposed at four corners thereof, and each connecting pipe 11 is connected to a supporting loop 12. An upper edge of the supporting loop 12 is provided with a first securing lip 13 and a lower edge of the supporting loop 12 is provided with a second securing lip 14 parallel to the first securing lip 13. A width of the second securing lip 14 is smaller than a width of the first securing lip 13, and preferably the width of the second securing lip 14 is ¼ to ⅓ of the width of the first securing lip 13. The woven body 20 has a shape corresponding to an enclosed space formed by the connecting pipes 11 and the supporting loop 12, and the woven body 20 extends from the second securing lip 14 into the frame member 10 and is welded onto the first securing lip 13 facing the second securing lip 14. The fram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shelving structure | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com