Atomizing apparatuses, systems, and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

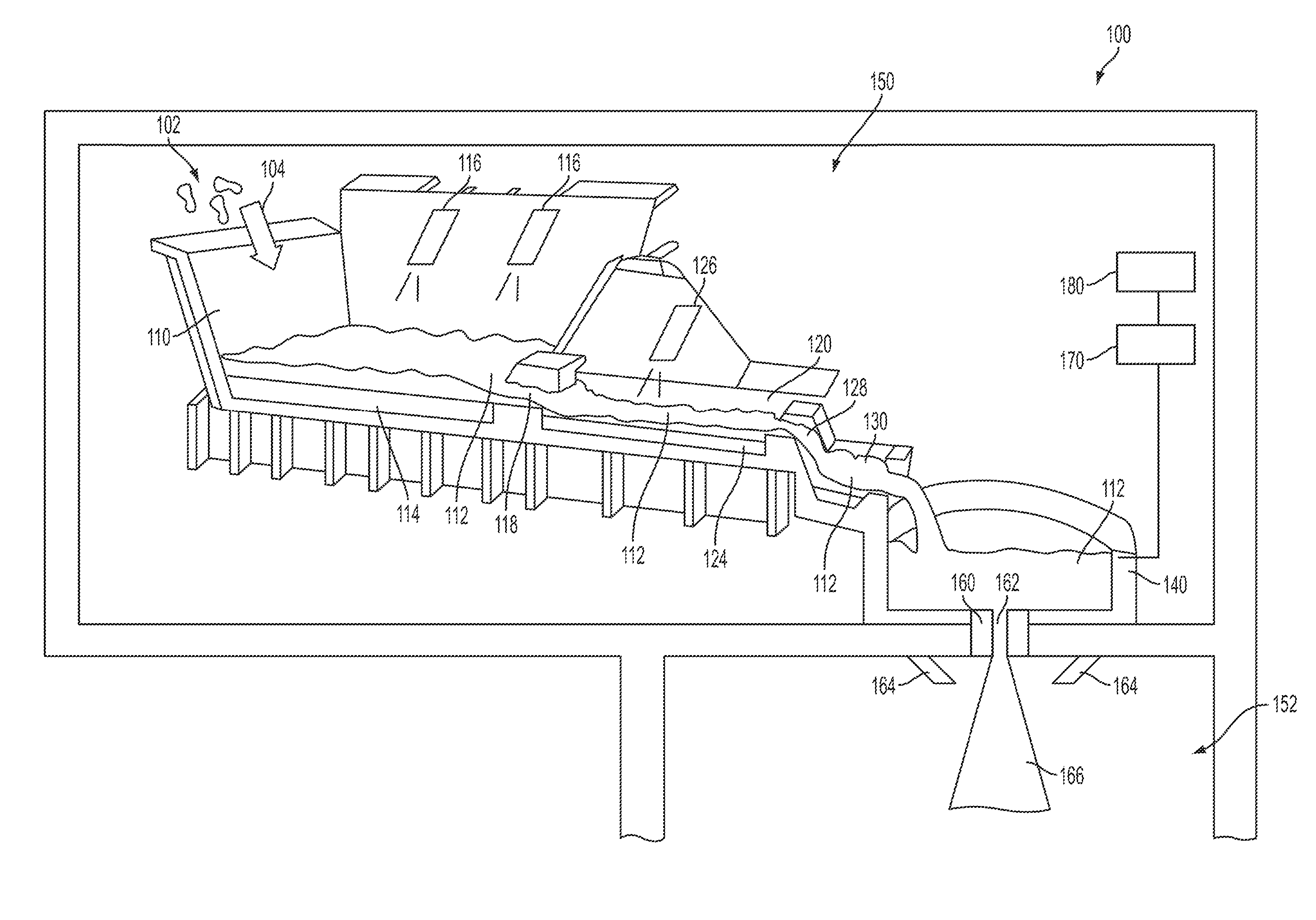

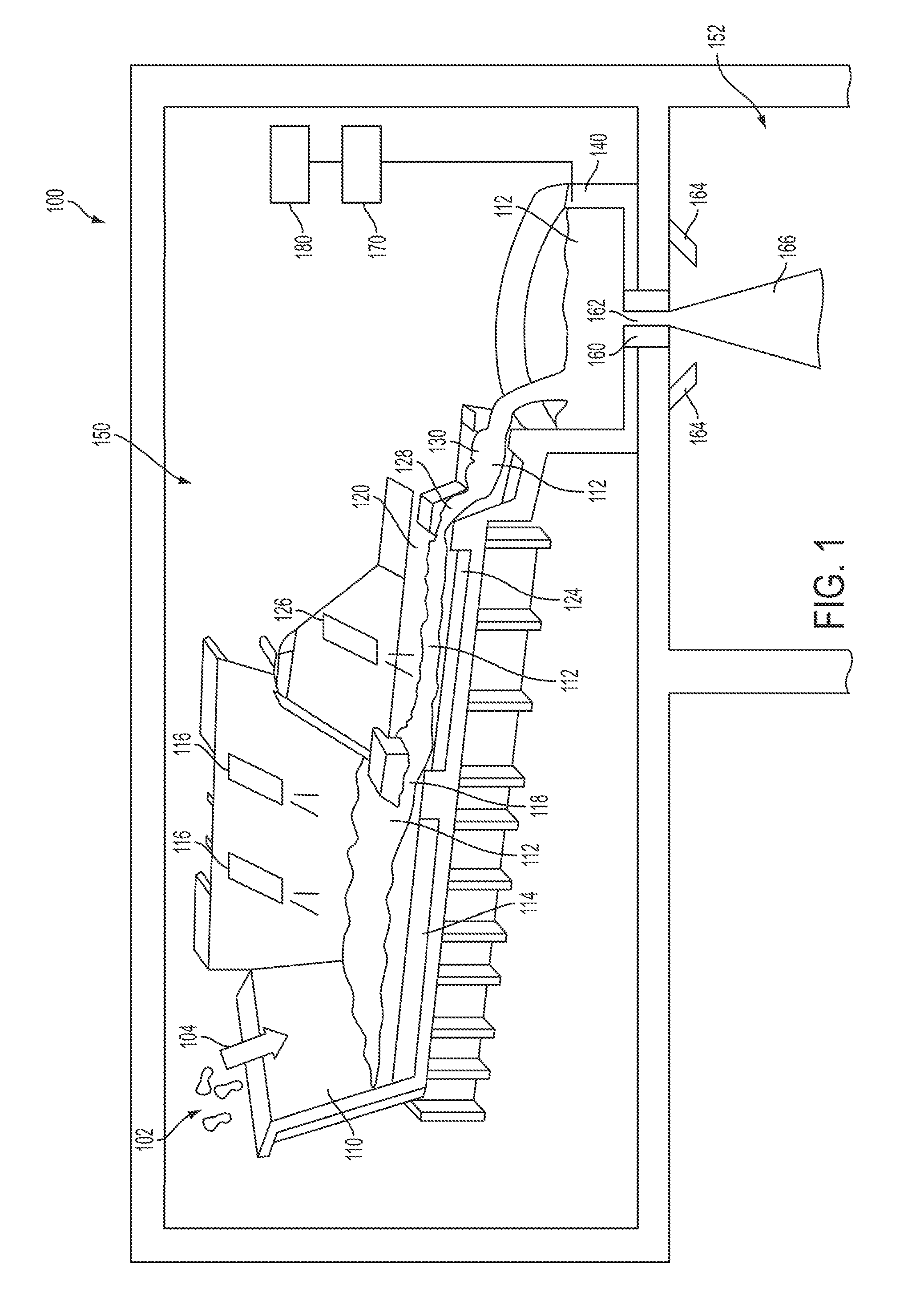

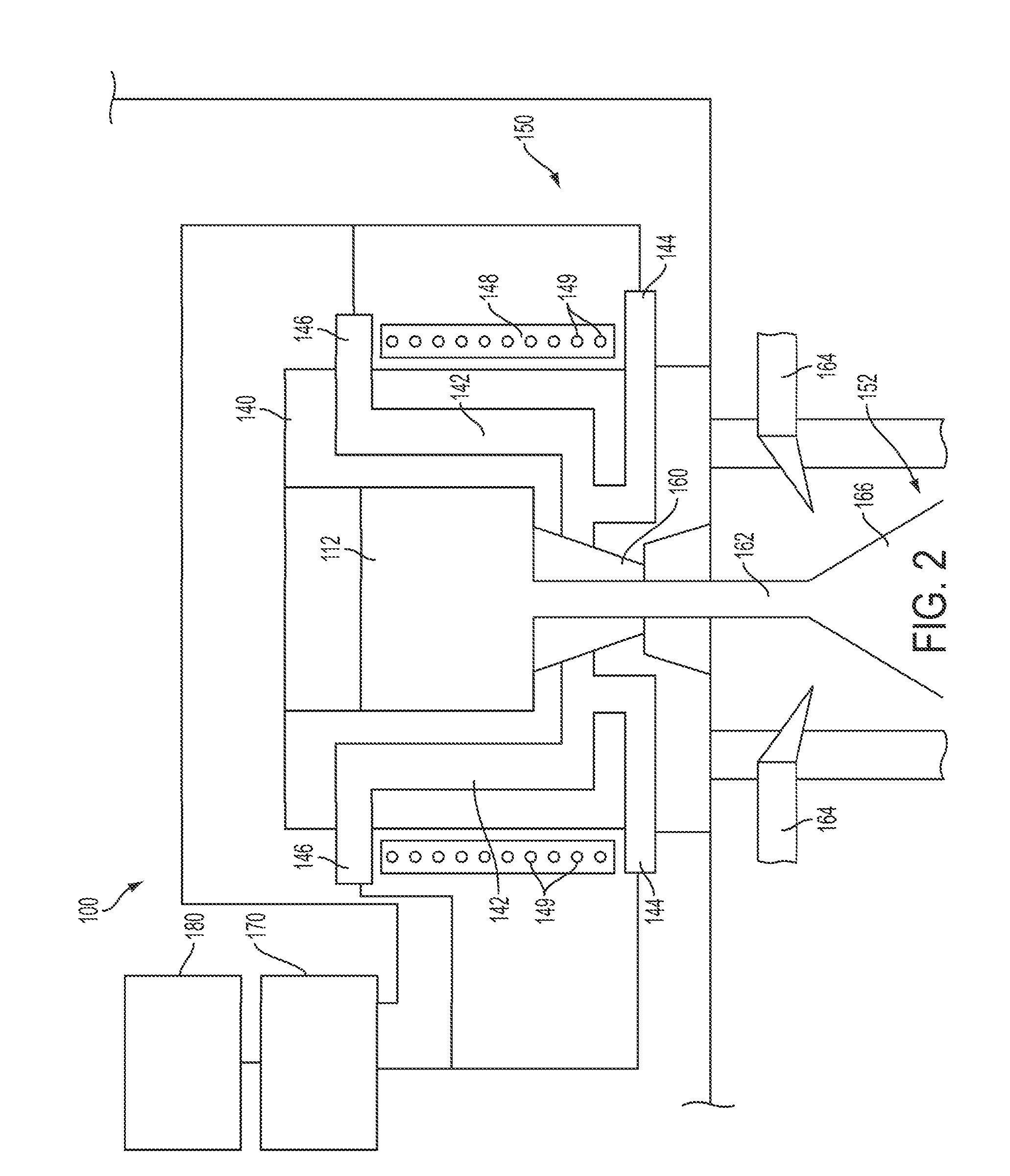

[0030]According to certain non-limiting embodiments of an atomizing system according to the present disclosure, the atomizing system can include a tundish and / or a nozzle having an internal channel defined therein. The tundish and / or the nozzle can be comprised of a material having a material composition that is identical or substantially identical to a material composition of the molten material positioned in and / or flowing through the tundish and / or the nozzle. A molten heat transfer medium can flow through the internal channel(s) to facilitate heat transfer to and / or from the tundish and / or the nozzle. For example, the molten heat transfer medium can heat the tundish and / or the nozzle to prevent solidification of the molten material within the nozzle. Also, in certain embodiments, the molten heat transfer medium can cool the tundish and / or the nozzle as the molten material flows through the tundish and / or the nozzle.

[0031]To prevent the erosion and contamination of molten materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap