Vacuum or gas protection smelting and casting equipment for continuous production

A technology of vacuum smelting and gas protection, applied in the field of smelting, pouring and atomization preparation of metal powder with low oxygen content, can solve the problems of low production efficiency, no good solution, difficult automatic continuous production, etc., and achieve equipment production and maintenance Increased efficiency and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

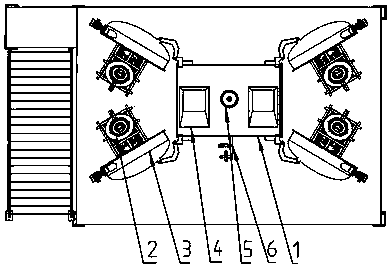

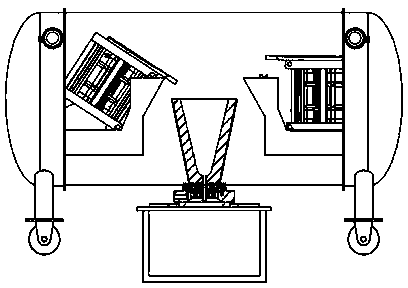

[0017] Embodiment 1, continuous vacuum / gas protection smelting casting casting production equipment.

[0018] The concrete technology embodiment that the present invention adopts: adopt horizontal vacuum smelting furnace chamber 1, close the attached figure 1 In the combination mode shown, there is a furnace door at both ends of the vacuum furnace shell. After the vacuum environment is provided by the vacuum unit or the protective gas is filled, the smelted material is fed by a displacement-type sealed feeding device 4 (the valve on the first floor is opened, and the valve on the second floor is closed. At this time, the material is charged. ; the valve on the first floor is closed, the valve on the second floor is closed, then vacuumize or gas replacement; the valve on the first floor is closed, the valve on the second floor is opened, and the material is loaded into the smelting furnace at this time) into the 2 crucibles of the induction heating smelting furnace body, or By ...

Embodiment 2

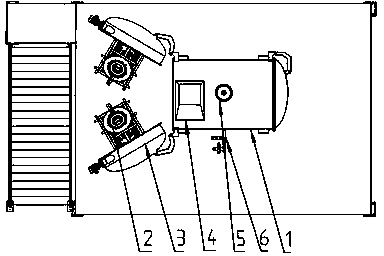

[0021] Embodiment 2, continuous vacuum / gas protection smelting and pouring atomized metal powder production equipment.

[0022] The concrete technology embodiment that the present invention adopts: adopt horizontal vacuum smelting furnace chamber 1, close the attached image 3 In the combination mode shown, there is a furnace door at both ends of the vacuum furnace shell. After the vacuum environment is provided by the vacuum unit or the protective gas is filled, the smelted material is fed by a displacement-type sealed feeding device 4 (the valve on the first floor is opened, and the valve on the second floor is closed. At this time, the material is charged. ; the valve on the first floor is closed, the valve on the second floor is closed, then vacuumize or gas replacement; the valve on the first floor is closed, the valve on the second floor is opened, and the material is loaded into the smelting furnace at this time) into the 2 crucibles of the induction heating smelting fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com