Aluminum shotgun shell case, methods of making, and using the same

a technology shell case, which is applied in the field of aluminum shotgun shell, can solve the problems of not being widely used in aluminum shotgun shell cases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case 20

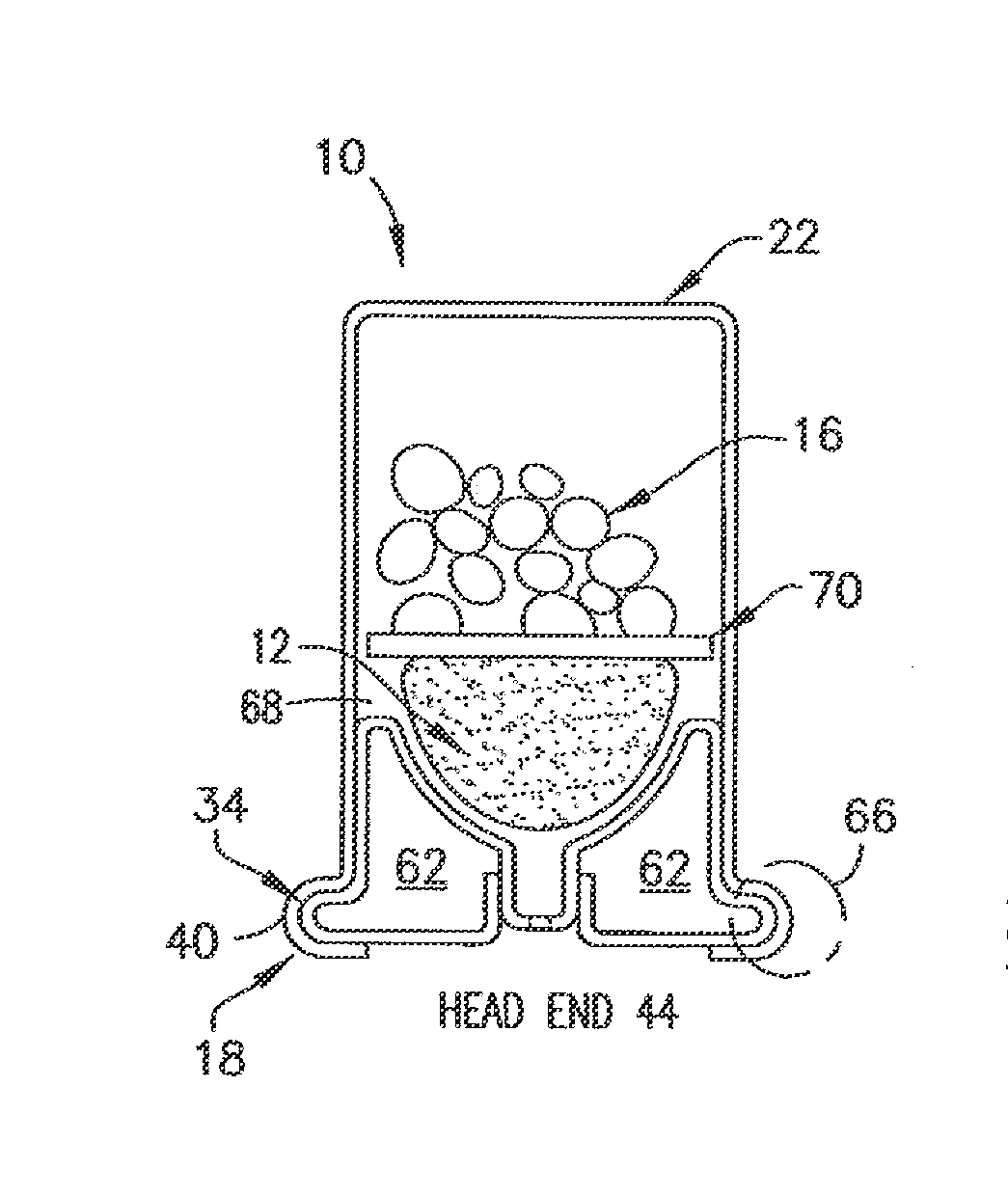

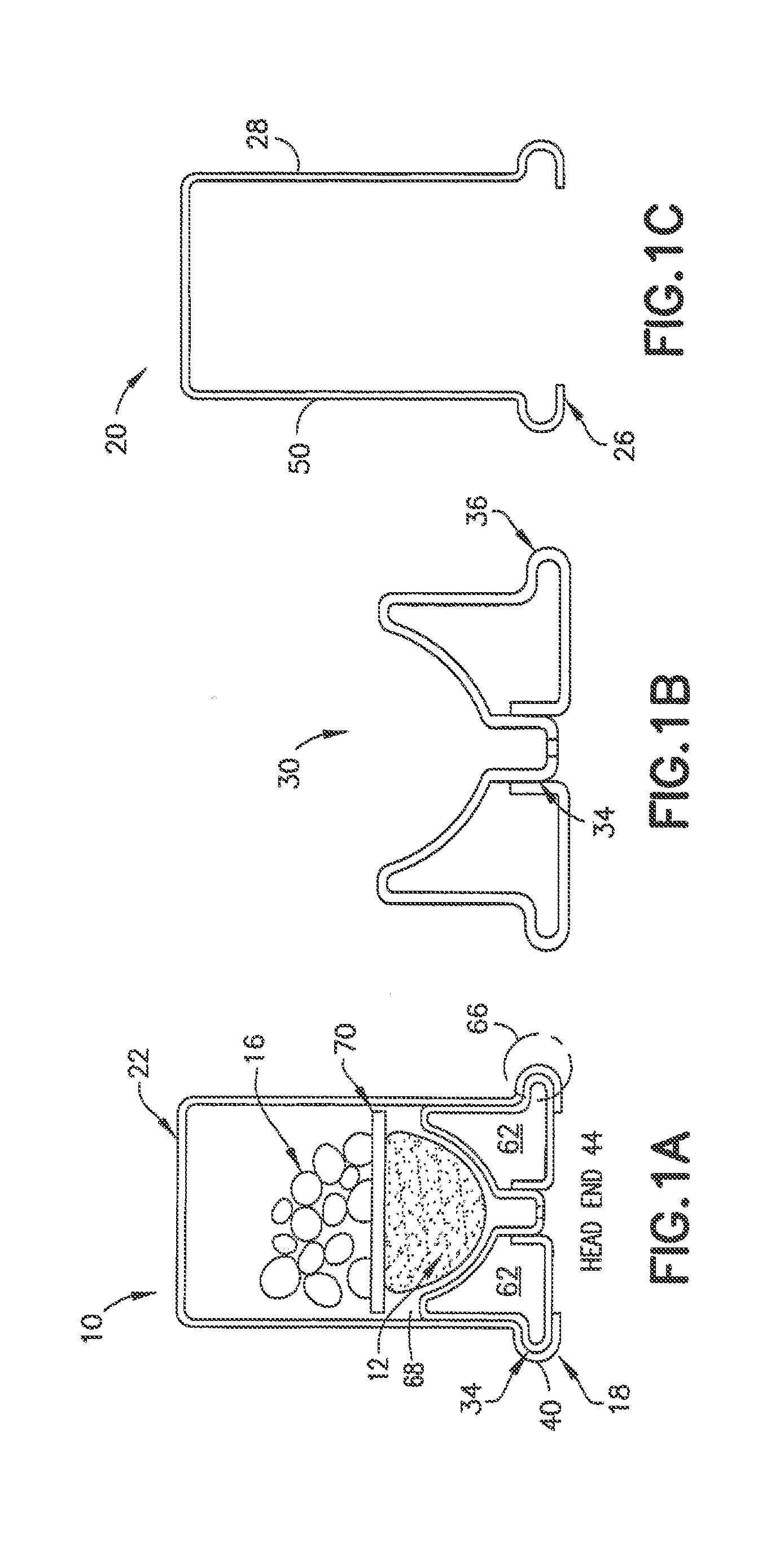

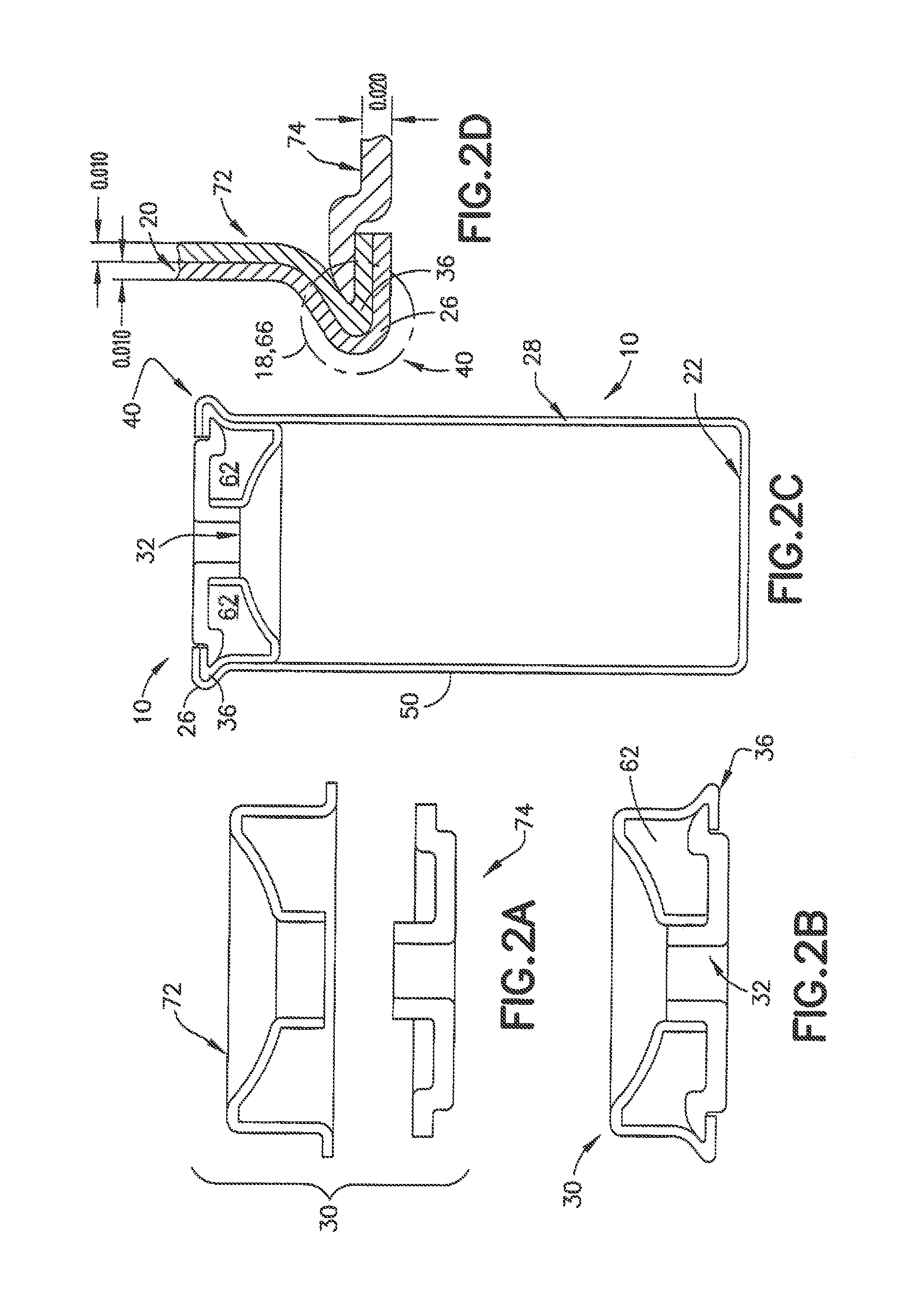

[0152]shot shell 10[0153]case 20[0154]mouth end 22[0155]cap 24[0156]rim (of case) 26[0157]sidewall of ease 28[0158]base assembly 30[0159]upper portion (of base assembly) 72[0160]lower portion (of base assembly) 74[0161]primer cup 32[0162]sealant 34[0163]mating edge (of base assembly) 36[0164]shell rim (with a circumferential edge) 40[0165]base assembly end 42[0166]head end 44[0167]score 46[0168]score pattern 48[0169]surface treatment / feature 50[0170]coating 52 (one embodiment of 50)[0171]additive to coating 54 (one embodiment of 50)[0172]paint 58 (one embodiment of 50)[0173]adherent 64[0174]head wad 70[0175]inner powder chamber 68[0176]embossed design 56(one embodiment of 50)[0177]printed surface feature 58 (one embodiment of 50)[0178]grooved surface 60 (one embodiment of 50)[0179]projectile (e.g. shot / slug) 16[0180]wad 14[0181]powder 12[0182]primer 18[0183]buoy (void space in head end) 62[0184]forming seal 18 (e.g. formed via mechanical manipulation of at least one component, e.g. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com