Method and apparatus for acoustic downhole telemetry and power delivery system using transverse or torsional waves

a technology of transverse or torsional waves and power delivery system, which is applied in the field of acoustic communication and to pipes for gas and oil production, can solve the problems of greater power required for comparable operation, and achieve the effect of minimizing potential interference and improving link efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Acoustic-Electric Channels

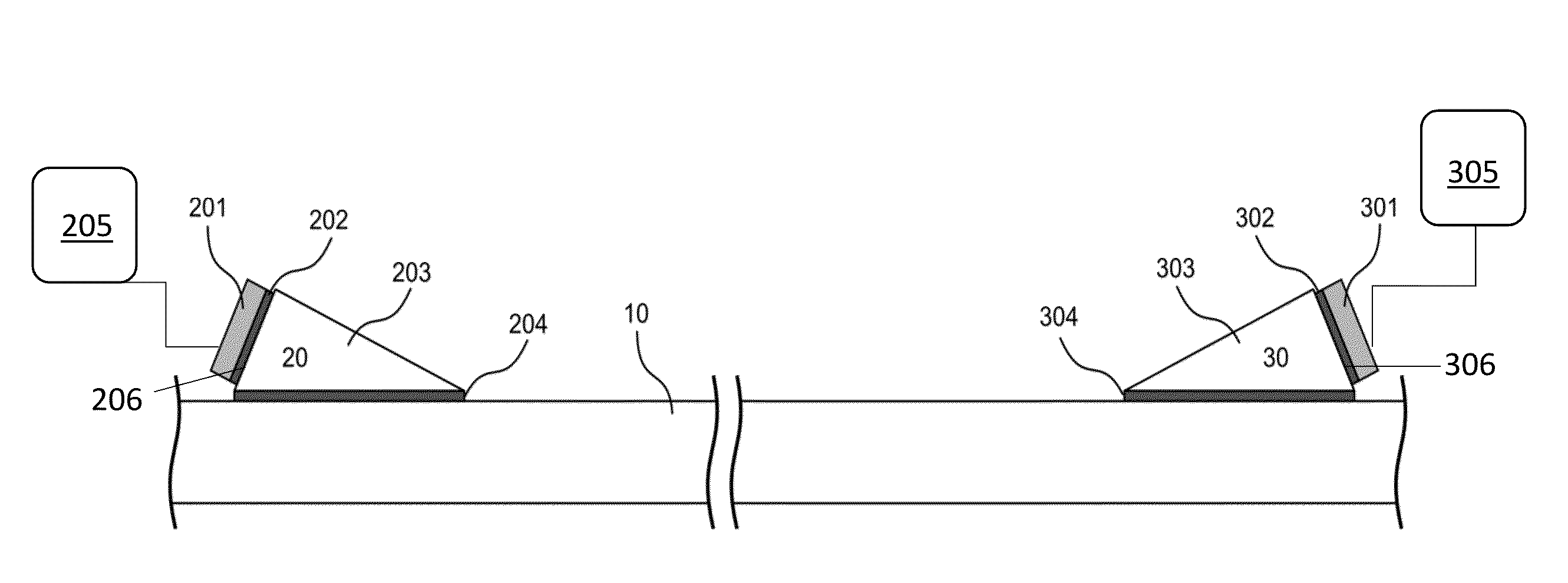

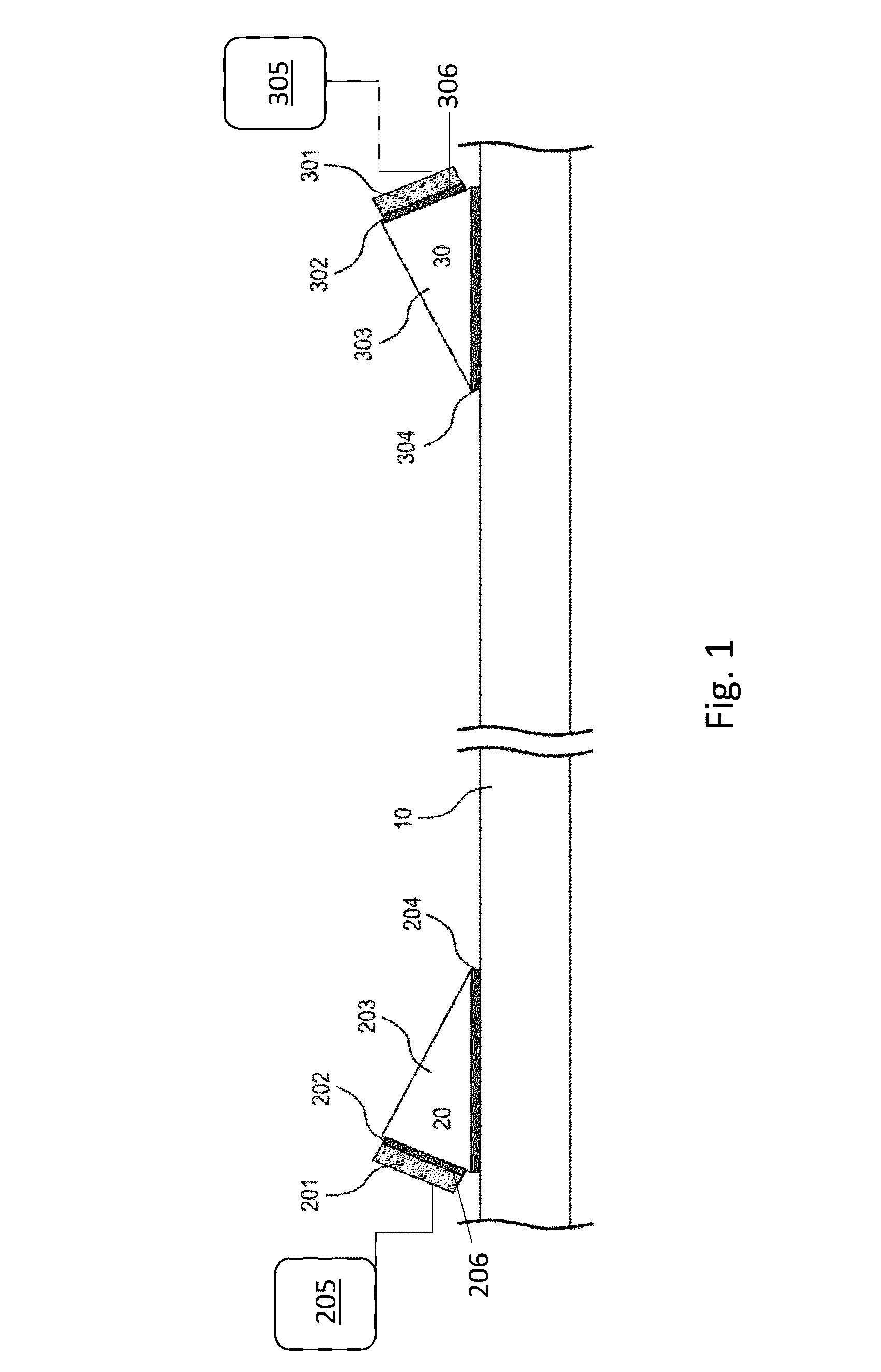

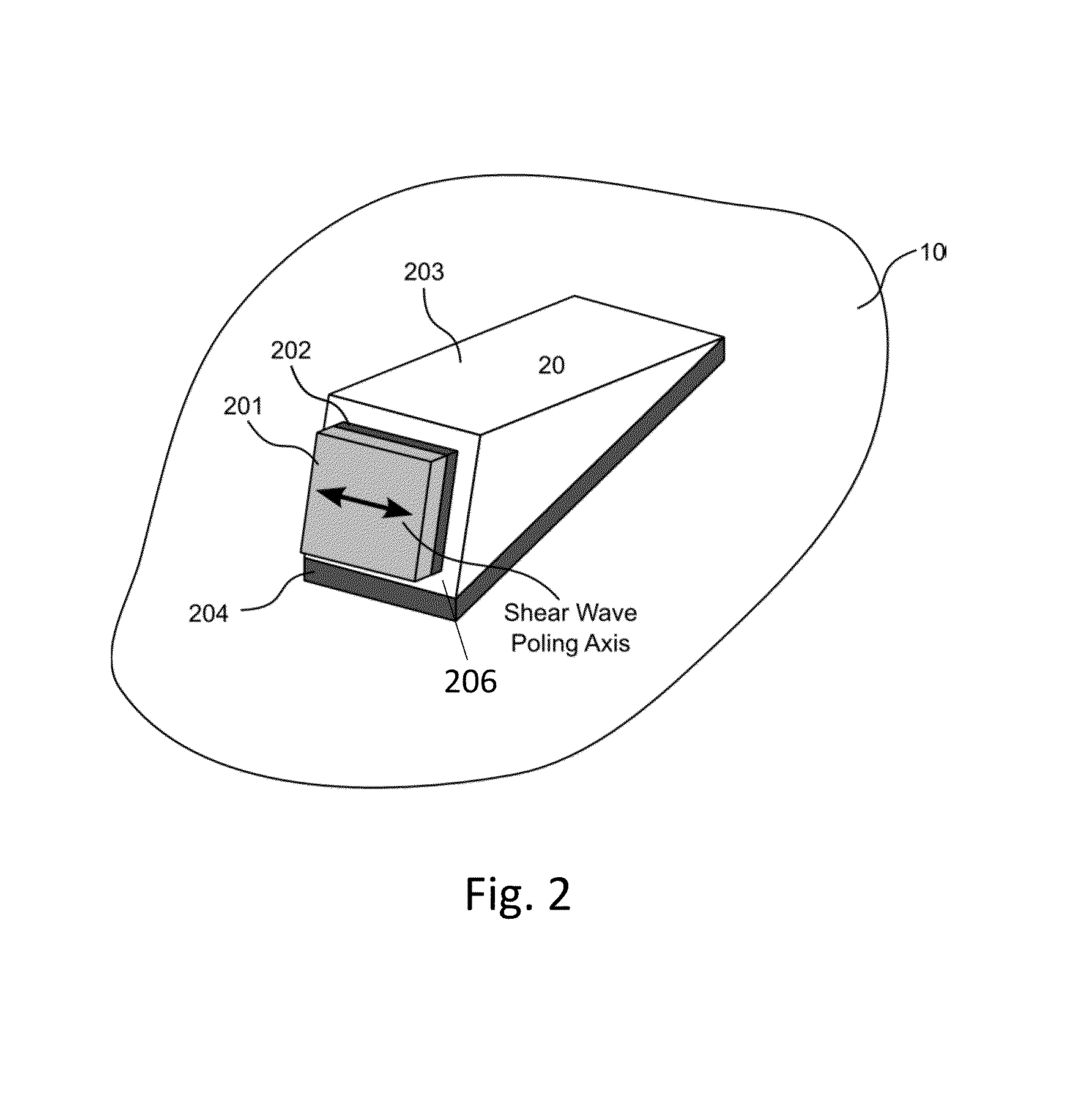

[0062]Referring now to the drawings, in which like reference numerals are used to refer to the same or similar elements, FIG. 1 schematically shows a simple acoustic electric channel for use with this invention. The channel includes a substrate 10, a transmit assembly 20, and a receive assembly 30. The assemblies depicted each include four basic components: a transducer 201,301 (e.g. a shear plate transducer), shear plate-wedge acoustic couplant 202,302, acoustic wedge 203,303 transition piece (or transition piece of alternative shape), and wedge-substrate acoustic couplant 204,304. Each transducer is linked to transmit 205 and receive 305 electronics, which may include sensors, signal processing electronics, power storage, signal transmission and reception elements, and / or other components which will vary between embodiments. FIG. 2 presents an isometric view of the transmit assembly 20, with the preferred particle displacement axis of the generated shear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com