Manufacturing method, processing apparatus and manufactured article for high tenacity reflective yarn

a reflective yarn and manufacturing method technology, applied in the field of manufacturing methods, processing apparatus and manufactured articles for high tenacity reflective yarn, can solve the problems of easy aging to lose its original effect, frequent replacement of reflective fabric of prior art, etc., and achieve good reflective effect, not easy to remove, and shorter service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The embodiment is described in details according to the diagrams:

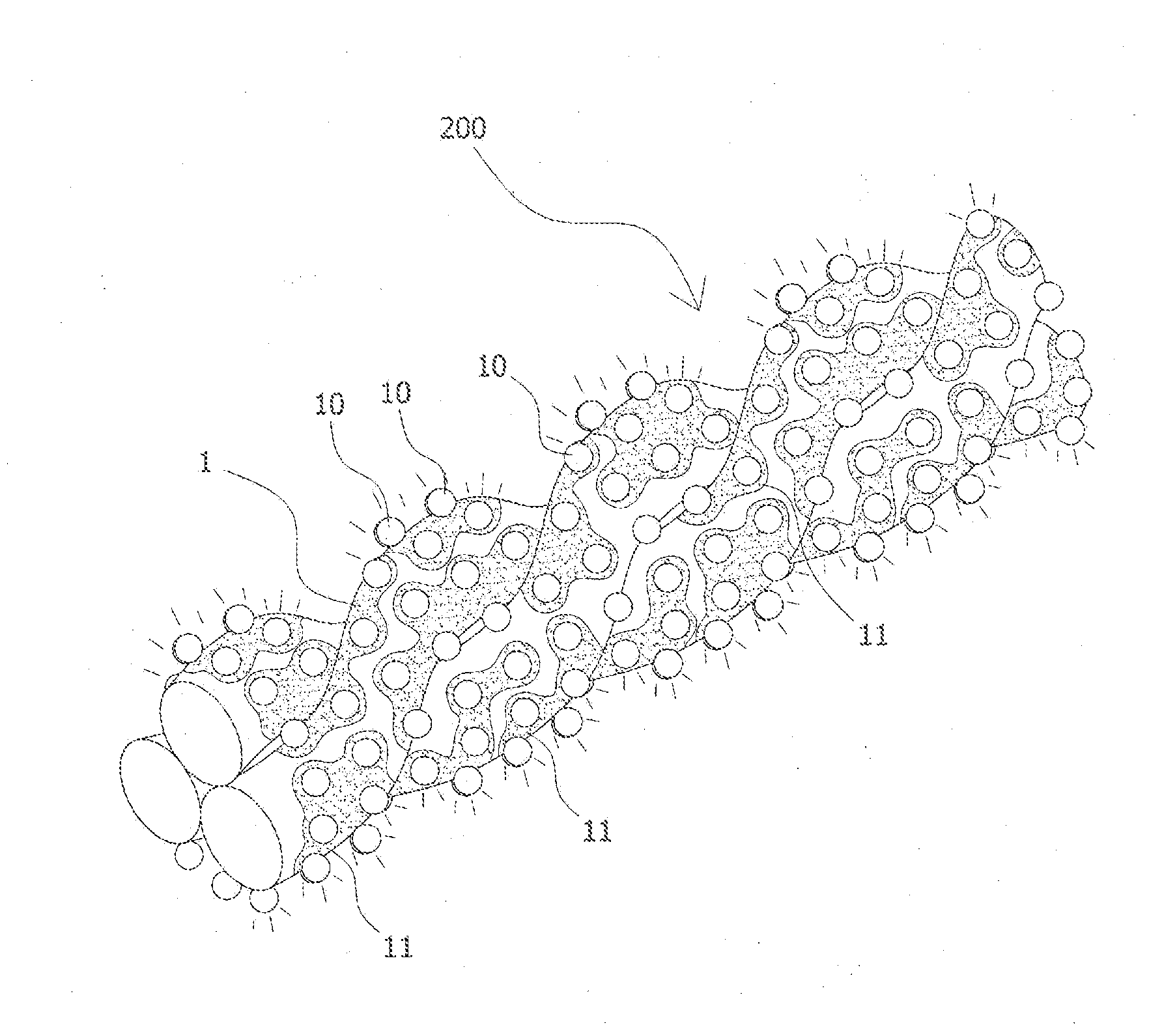

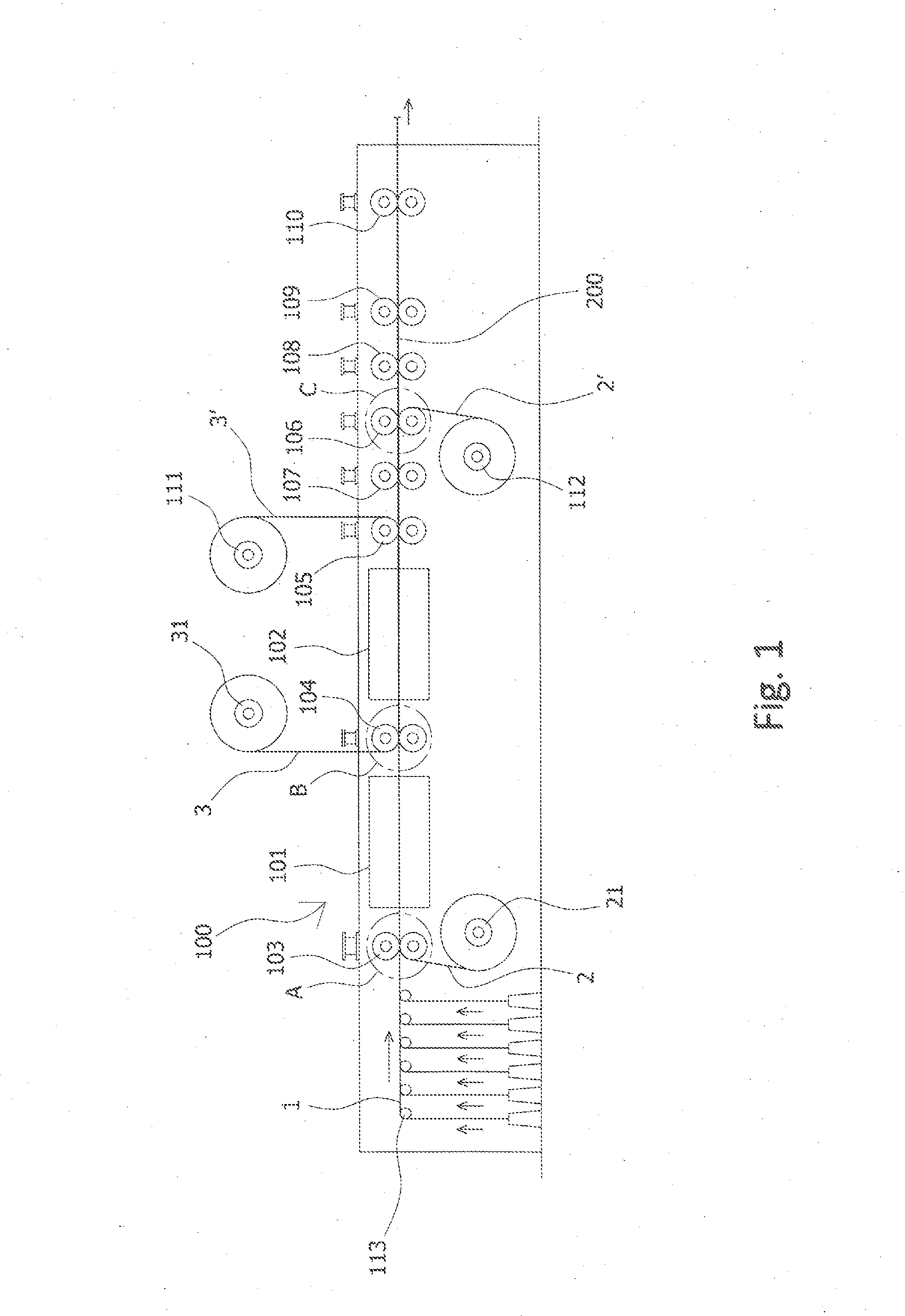

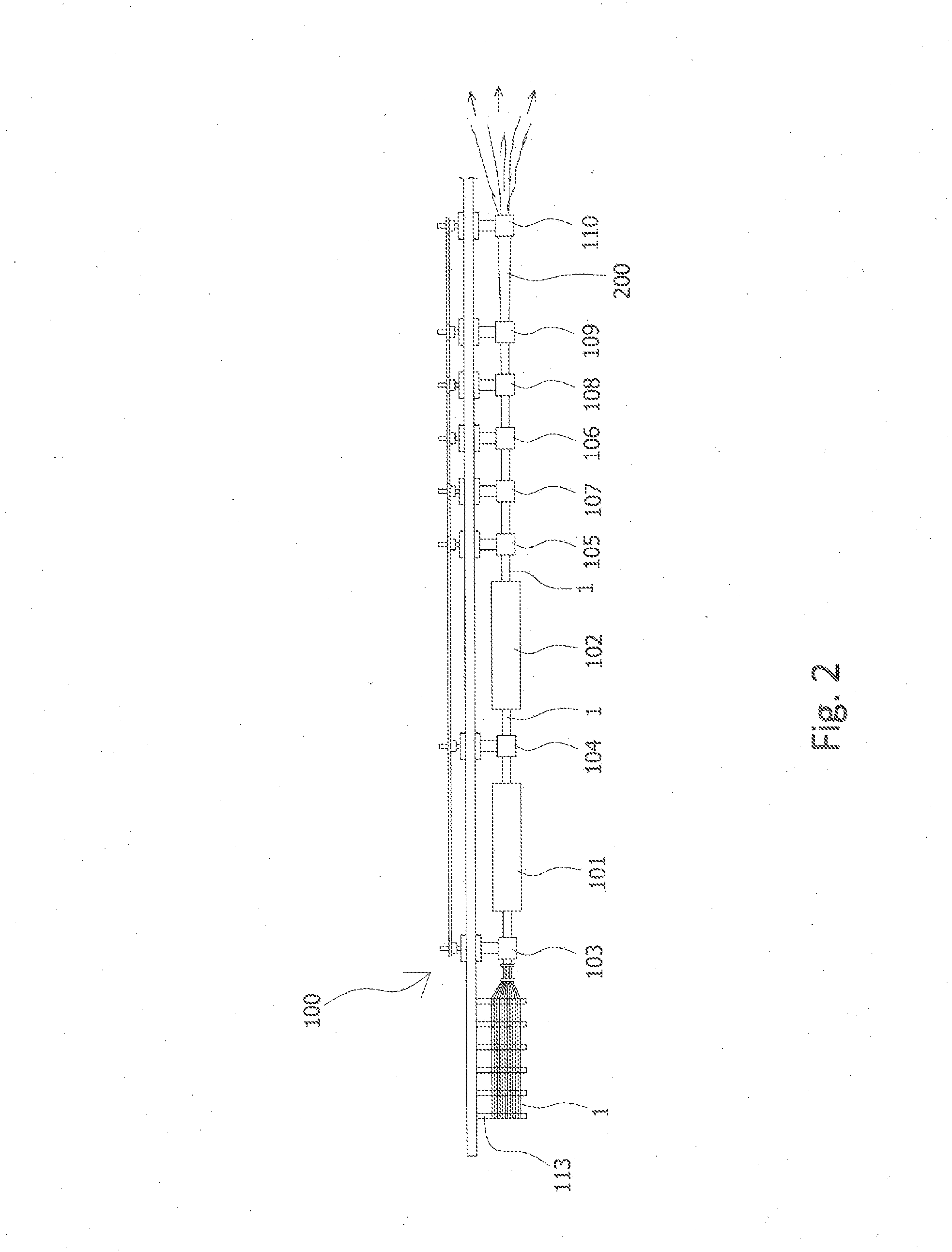

[0050]As shown in FIG. 1, 2, 4-6, 1. A manufacturing method for high tenacity reflective yarn, comprising the steps of: providing a plurality of high tenacity yarns (1) to a processing apparatus (100); transporting said high tenacity yarns (1) from a front end of the processing apparatus (100) toward a rear end thereof through first conveyor wheels (103) that makes the tenacity yarns (1) an interval therebetween, and introducing first reflective films (2) to a lower part of the high tenacity yarns (1) by a lower supplying wheel (21) disposed under the tenacity yarns (1), said first reflective films (2) being tightly attached to the lower part of the high tenacity yarns (1) through the first conveyor wheels (103); transporting the high tenacity yarns (1) by the first conveyor wheels (103) to an first oven (101) of the processing apparatus (100) for first time heating that will melt viscose (11) disposed in single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com