Swirler for a burner of a gas turbine engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

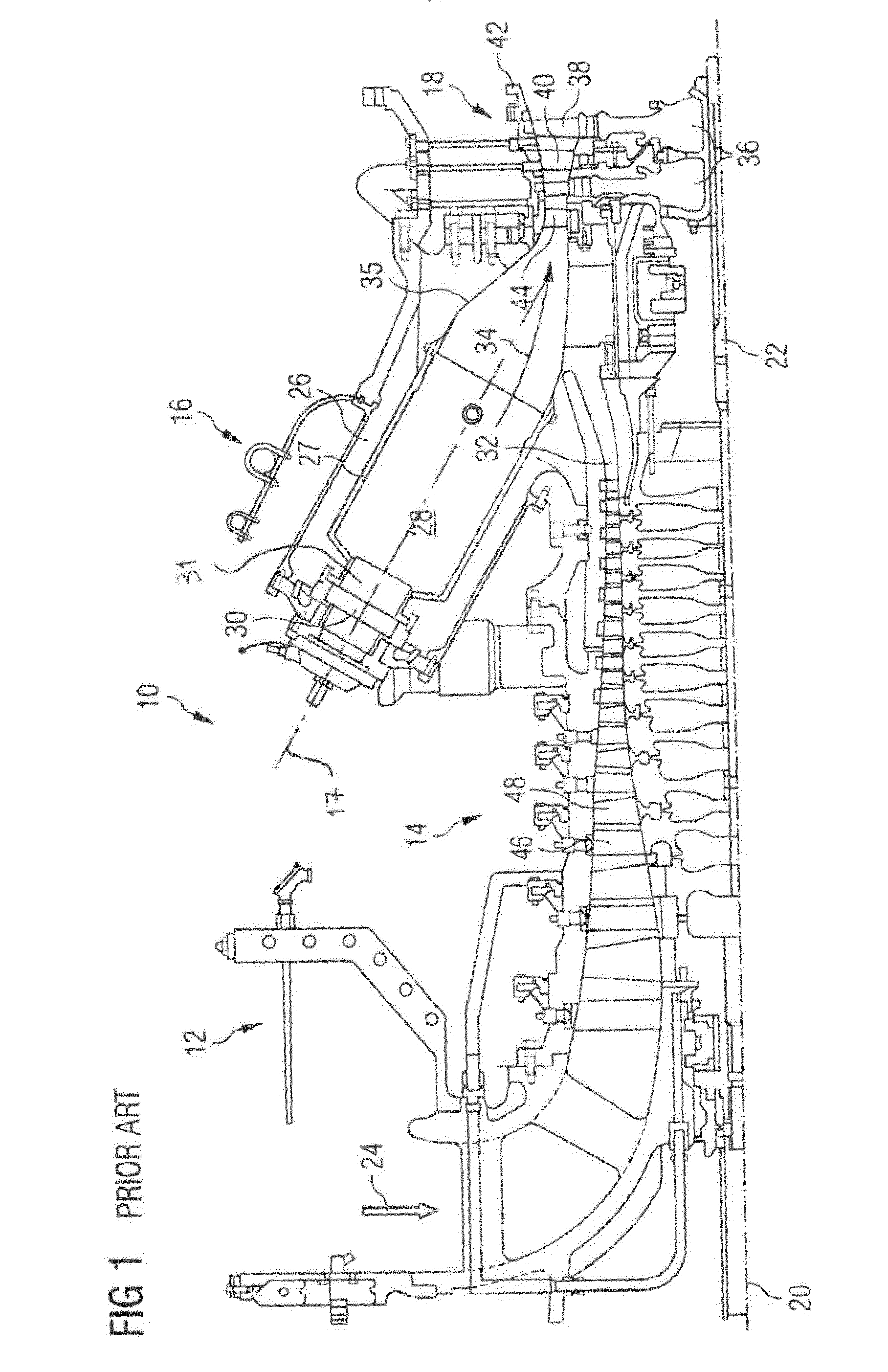

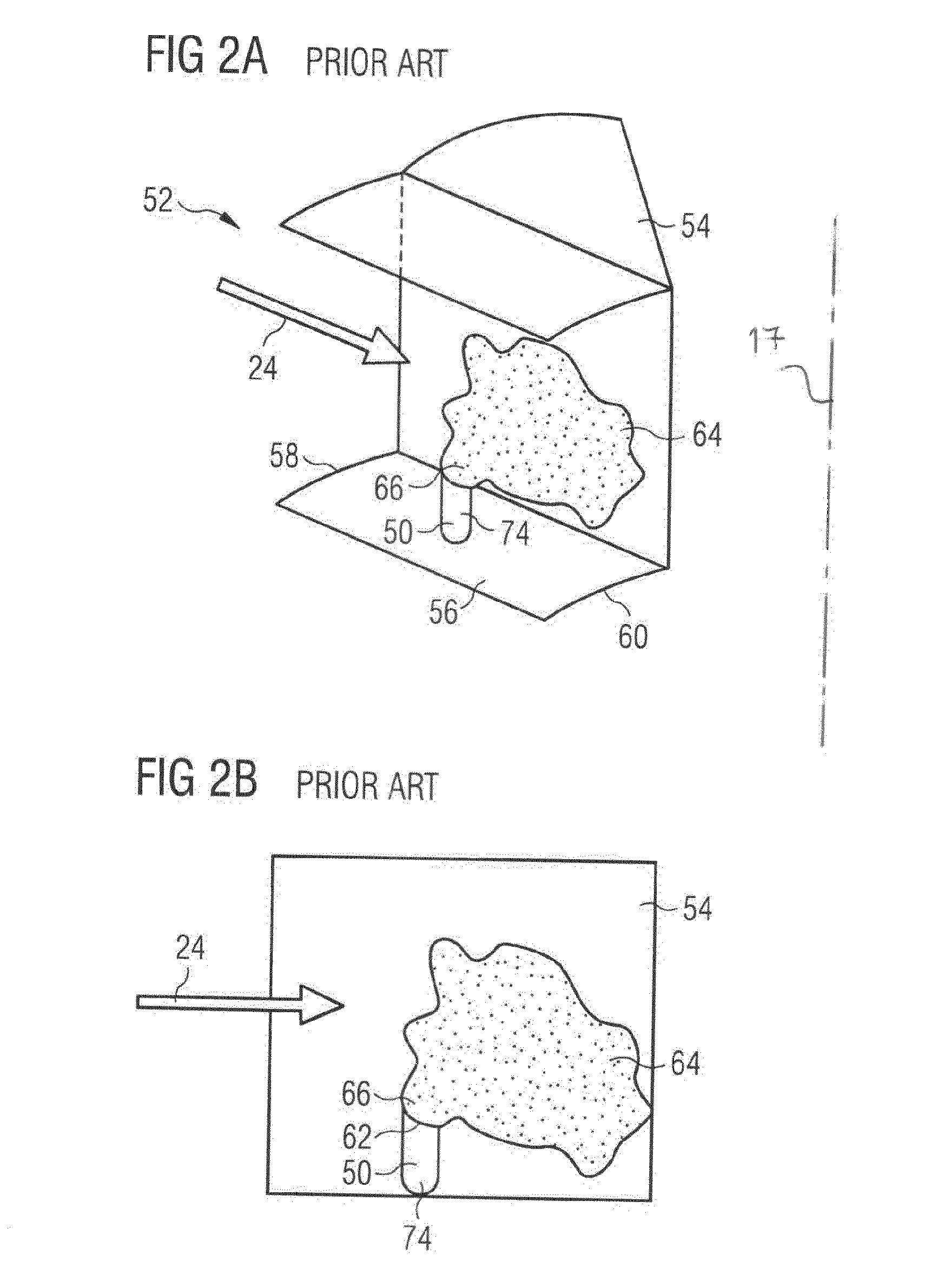

[0029]Elements having the same functions and mode of action are provided in FIGS. 1, 2a, b and 3a, b, c with the same reference signs.

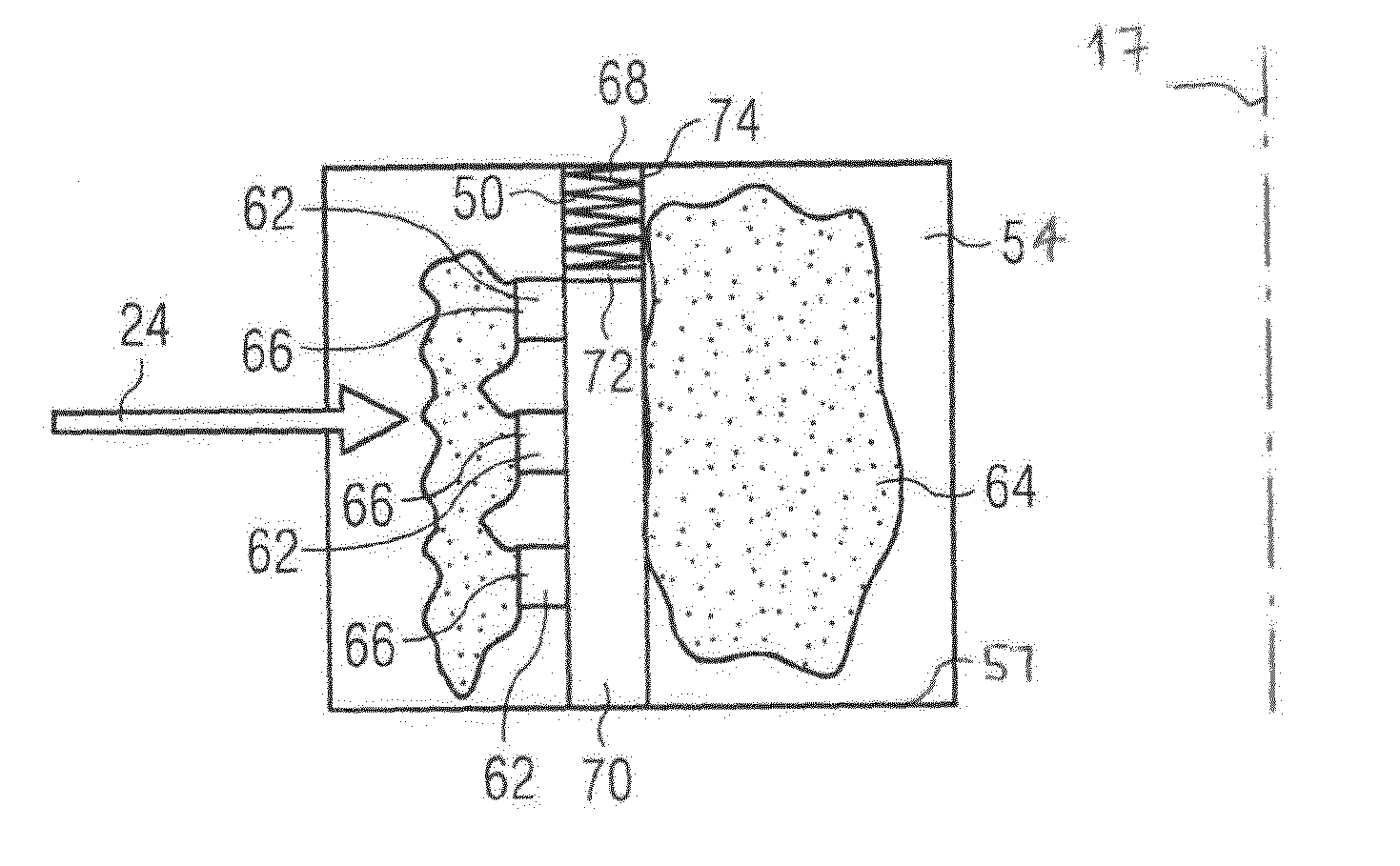

[0030]In FIG. 2a, 2b parts of a swirler 52 according to prior art are shown. In detail, one of the vanes 54 and a mixing channel 56 is shown. In the mixing channel 56 air 24 is channelled from a radially outer end 58 to a radially inner end 60 of the mixing channel 56. Inside the mixing channel 56 a fuel injection means 50 is placed. This fuel injection means 50 is in this embodiment constructed as a fuel injection lance 74. At the end of the fuel injection lance 74 an injection port 62 is located. Through this injection port 62 a fuel injection 66 of fuel 64 into the air 24 is carried out. The shown fuel injection lance 74 is optimized and designed for a full load operation of the gas turbine engine 10. Therefore, at part load operations of the gas turbine engine less fuel 64 is injected 66 into the air 24. An atomization of the complete fuel 64 cann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com