Dental veneers and methods of manufacture

a technology of dental veneers and manufacturing methods, applied in the field of dental veneers, can solve the problems of needing laboratory work with a considerable expense of time and money, and producing new dental veneers, and achieve the effect of reducing the amount of natural dental tissu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

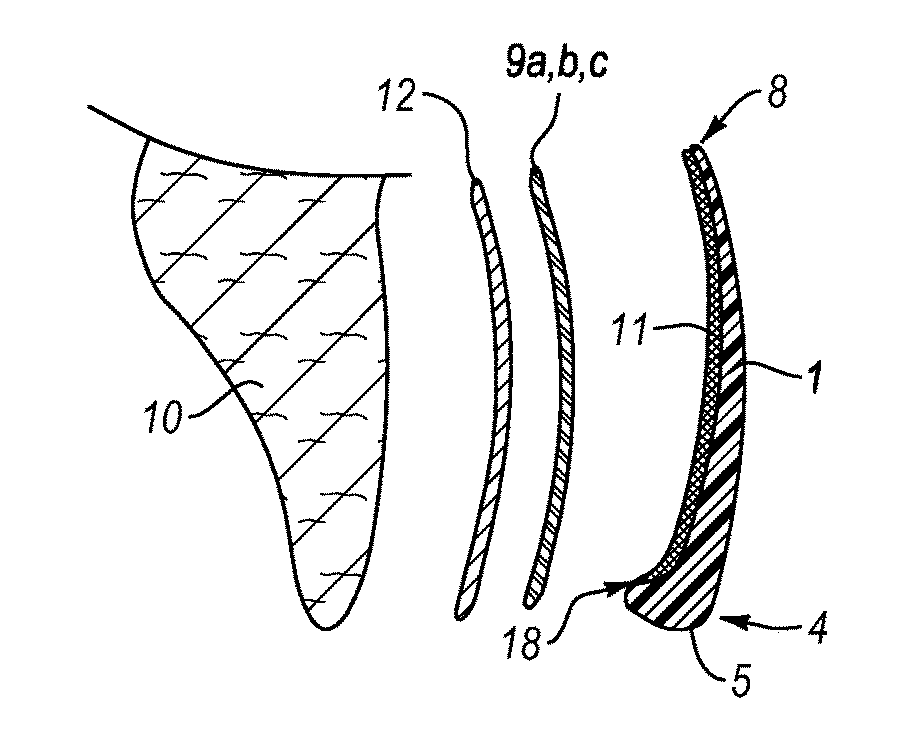

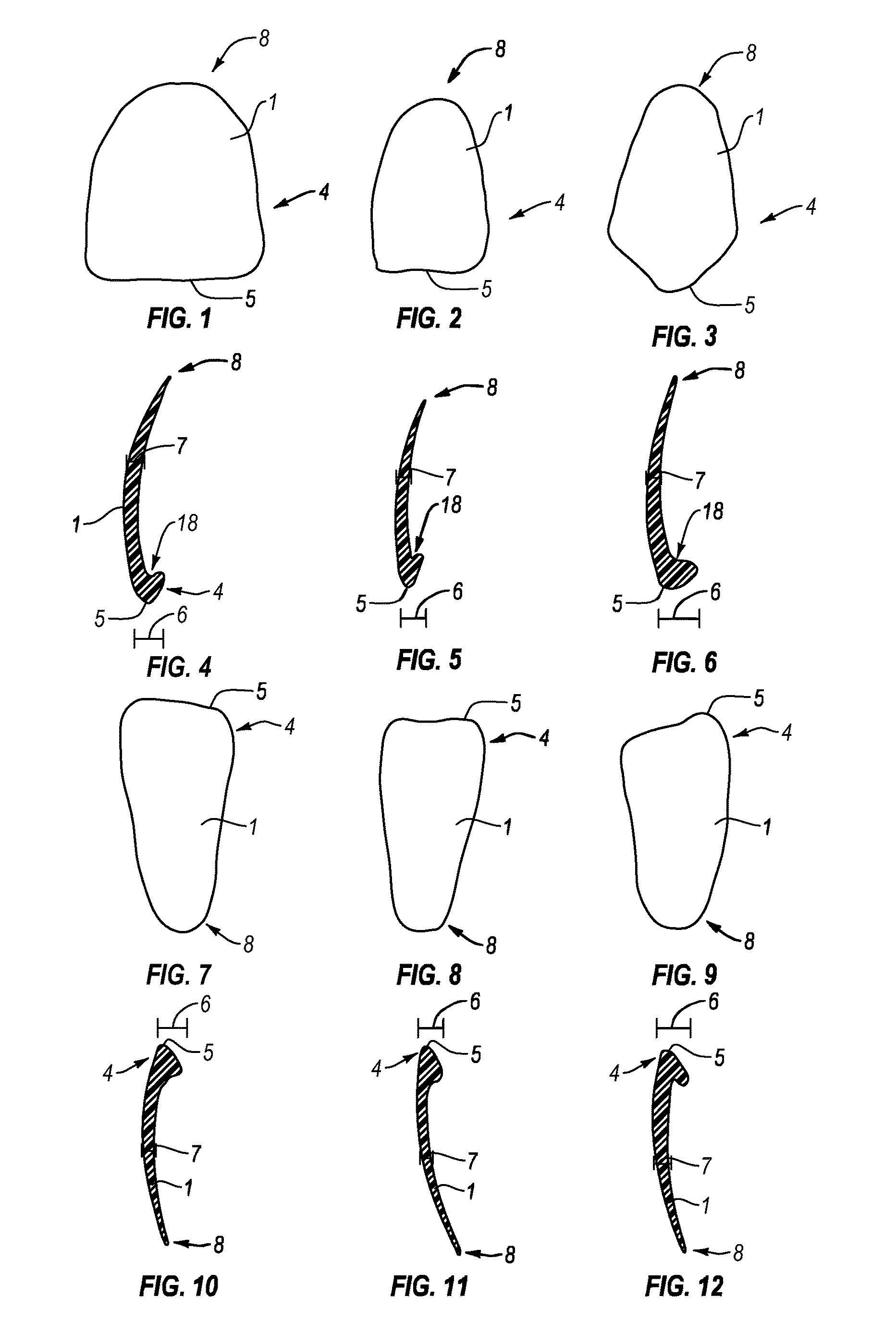

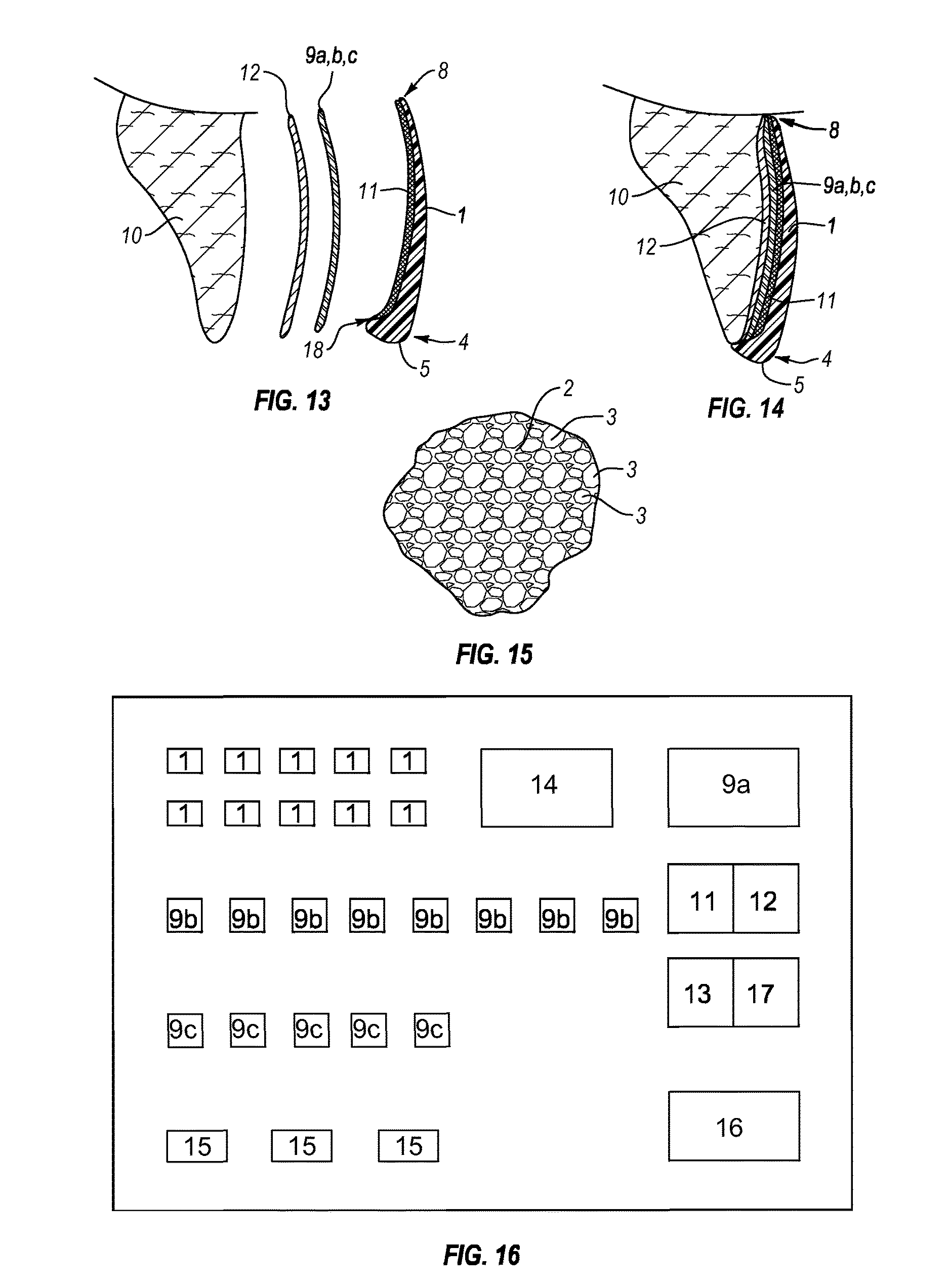

[0024]Disclosed herein are dental veneers made from composite materials comprising one or more types of organic binder and one or more types of solid particulate filler.

[0025]With regards to their shape, dental veneers of this type can be processed on site by the dentist using the common tools of his / her practice and thus be adjusted to the conditions given in the patient. This eliminates the necessity of producing the dental veneers in a lab.

[0026]Similar to prior veneers, the dental veneers according to the invention have solid bodies, which may be placed upon a tooth stump and / or tooth prepared in manners known in the prior art, in order to appropriately cover the front of a discolored and / or damaged tooth and optically improve it. In one or more embodiments of the invention, dental veneers have solid bodies which are at least partially shaped in a curved cup-like fashion. Primarily due to the solid particles used as fillers, the dental veneers according to the invention also hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain sizes | aaaaa | aaaaa |

| grain sizes | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com