Surface Reinforced Concrete Masonry Units

a technology of reinforced concrete and masonry units, applied in the direction of walls, building components, constructions, etc., can solve the problems of reducing the design life of the structure, increasing the operation and maintenance costs, and reducing the durability, so as to reduce the self-weight of the wall, facilitate the bonding, and reduce the effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

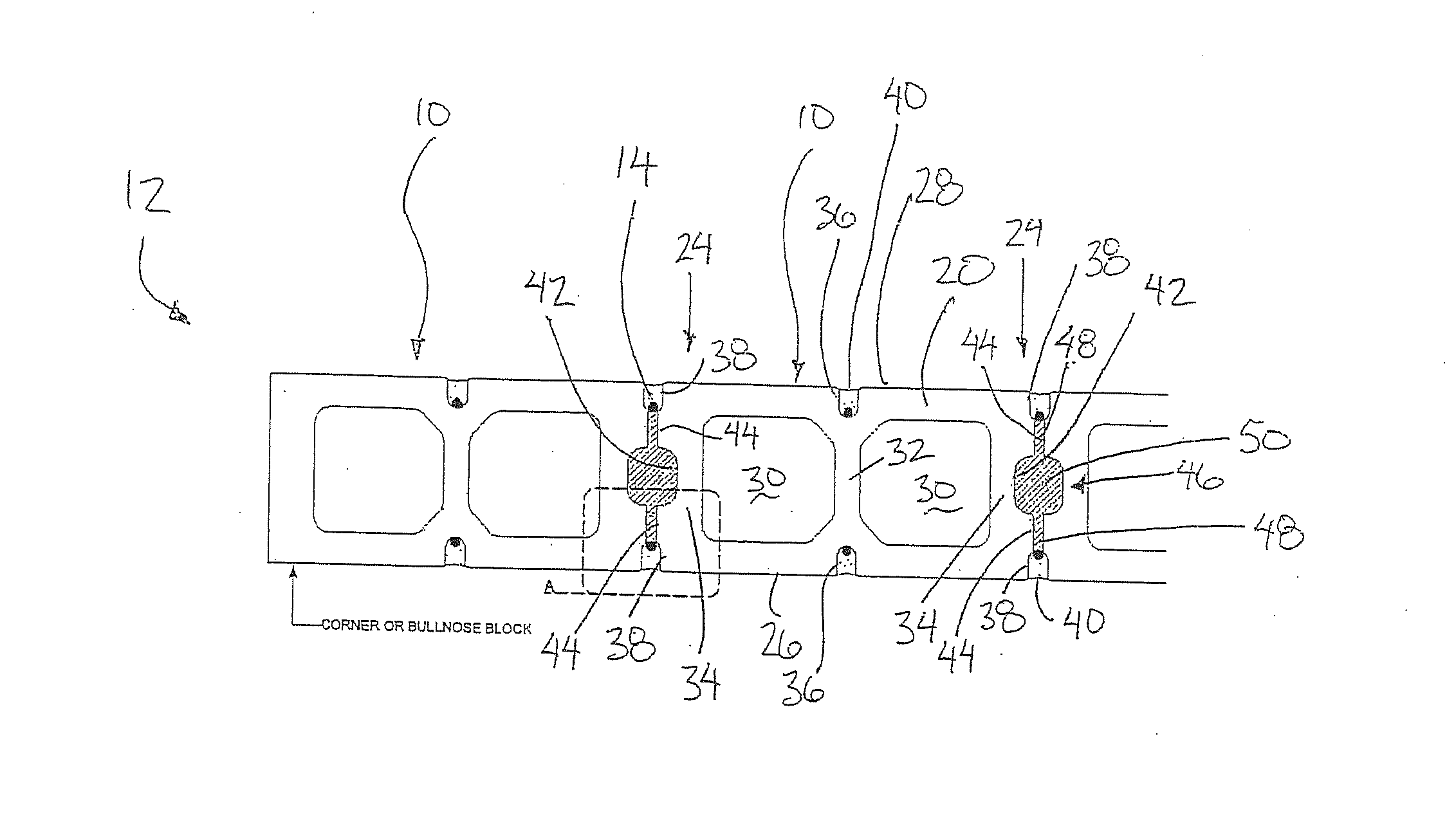

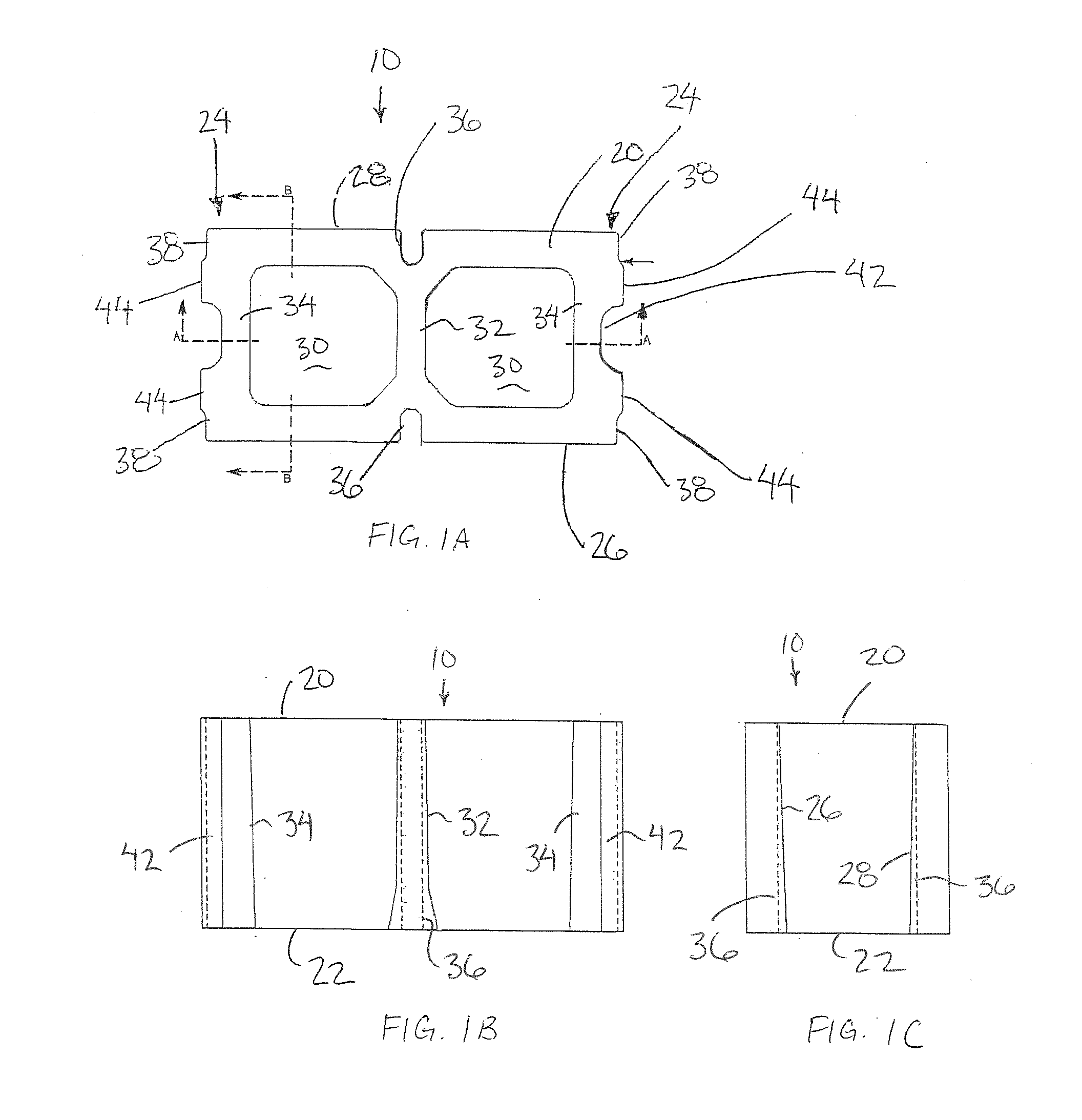

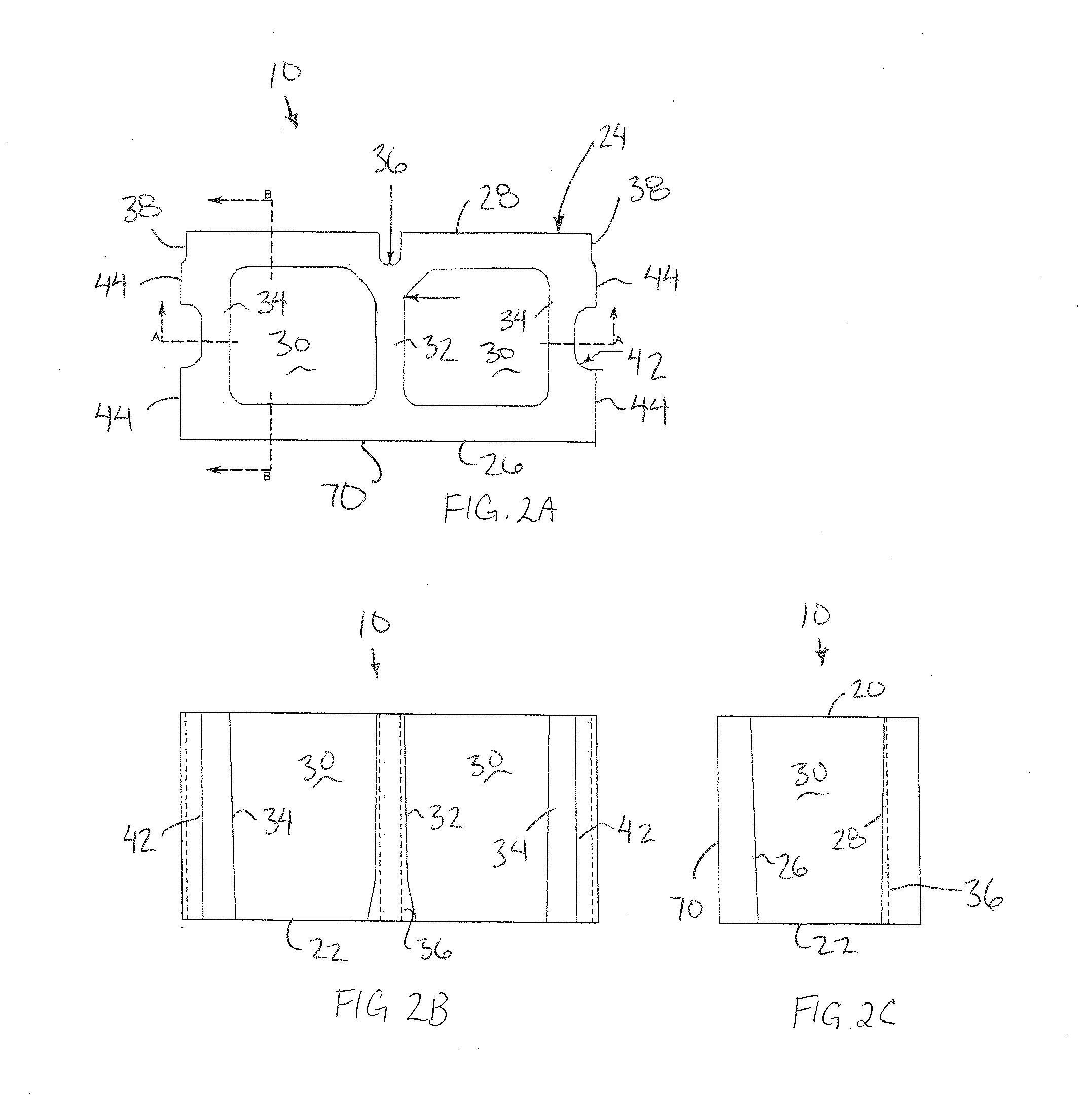

[0051]Referring to the accompanying figures, there is illustrated a masonry unit generally indicated by reference numeral 10. The masonry unit 10 is particularly suited for use in the construction of a masonry wall 12 as shown in FIGS. 4A through 4C. The masonry units 10 permit reinforcement members 14, for example conventional rebar or other forms of elongate reinforcement, to be recessed into one or both exterior surfaces of the assembled wall.

[0052]The wall 12 is typically constructed in a manner similar to the use of conventional concrete masonry units by abutting the units longitudinally end to end in rows with the rows being stacked one above the other. Each unit may be vertically aligned directly above a corresponding unit in the previous row therebelow, or more preferably each masonry unit 10 is offset longitudinally by half of the length of the unit relative to a corresponding unit of the previous row so that each masonry unit is engaged upon a portion of two additional mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com