Brake control device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0079]The first embodiment is described referring mainly to FIG. 5.

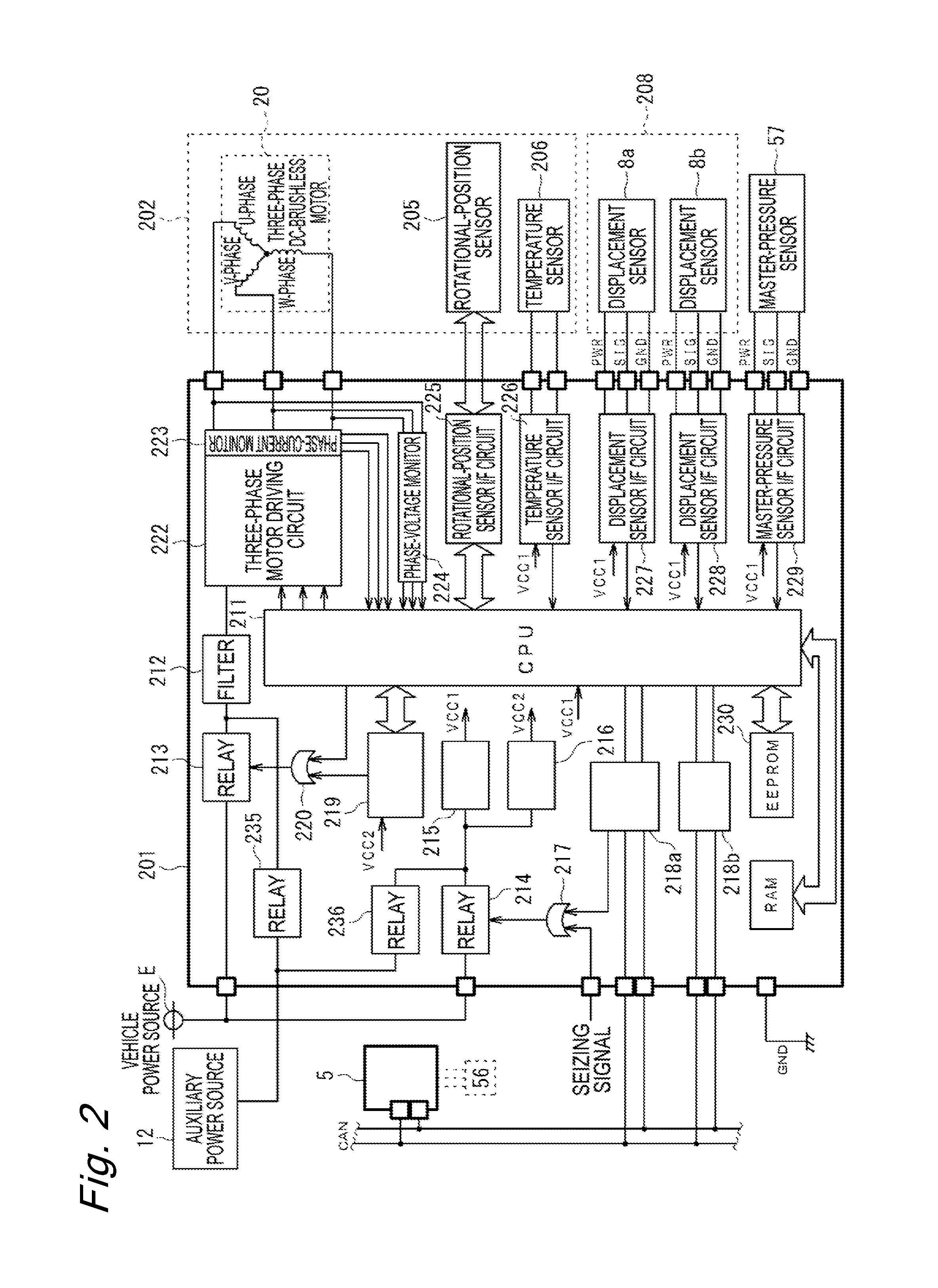

[0080]In the first embodiment, when the system end conditions are satisfied, the power-supply interruption control is executed to interrupt the vehicle power source E and supply the necessary electric power from the auxiliary power source 12. In this manner, the power-supply interruption control is continued by the master-pressure control device 3 until the electric power stored in the auxiliary power source 12 is depleted.

[0081]An example of a control flow for executing the power-supply interruption control according to this embodiment is illustrated in FIG. 5. Referring to FIG. 5, in Steps S50 to S53, the same processing as that performed in Steps S11 to S14 illustrated in FIG. 3 is performed. Then, when it is determined in Step 51 that the vehicle power source E does not fail, that is, when it is determined that the vehicle power source E is normal and the electric power is supplied from the vehicle electric power...

second embodiment

[0085]In the second embodiment, when the system end conditions are satisfied, the power-supply interruption control is executed to interrupt the vehicle power source E and supply the necessary electric power from the auxiliary power source 12 to the CPU 211 and the monitoring control circuit 219 when the amount of electric power (amount of charge) of the auxiliary power source 12 is equal to or larger than a given amount, so as to reduce the electric power consumption. Further, when the operation of the brake pedal 100, the operation of the master-pressure control device 3 is made possible immediately.

[0086]An example of a control flow for executing the power-supply interruption control according to this embodiment is illustrated in FIG. 6. Referring to FIG. 6, in Step S64 corresponding to Step S54 of the first embodiment, when the system end conditions have been satisfied, the power source is switched from the vehicle power source E to the auxiliary power source 12 in Step S65 so a...

third embodiment

[0088]In the third embodiment, when the system end conditions are satisfied, the power-supply interruption control is executed to interrupt the vehicle power source E and supply the necessary electric power from the auxiliary power source 12 to the CPU 211 and the monitoring control circuit 219. In this manner, the electric power consumption is reduced for a predetermined period of time and, when the operation of the brake pedal 100 is detected, the master-pressure control device 3 can operate immediately.

[0089]An example of a control flow for executing the power-supply interruption control according to this embodiment is illustrated in FIG. 7. Referring to FIG. 7, in Step S74 corresponding to Step S54 in the first embodiment, when the system end conditions have been satisfied, the power source is switched from the vehicle power source E to the auxiliary power source 12 in Step S75. In Step S76, it is determined whether or not a predetermined period of time has elapsed after the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com