Heat exchanger and a system for recovery of thermal energy from waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

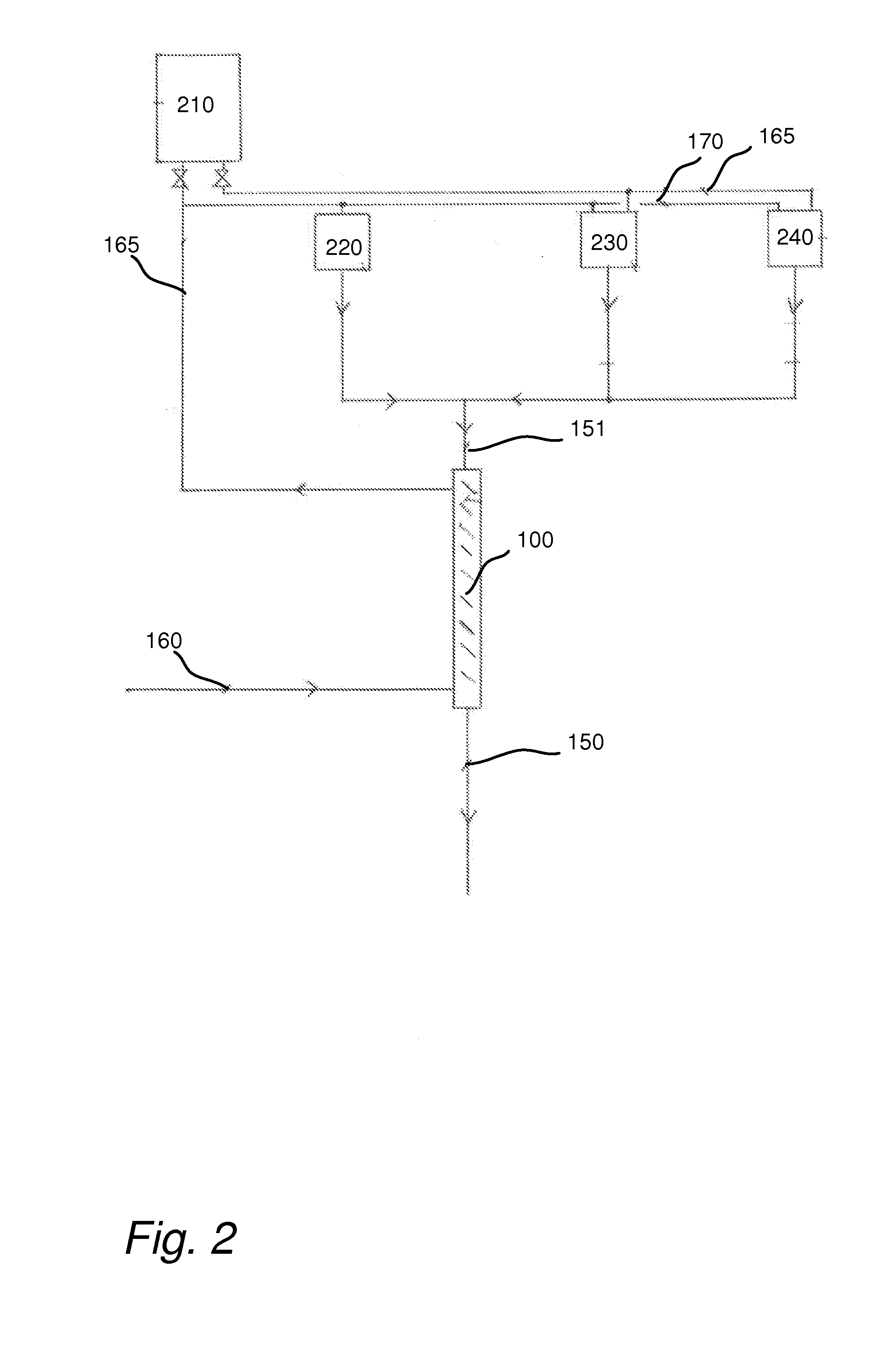

[0046]The heat exchanger according to the invention is based on the idea of saving energy by using thermal energy in the waste water to preheat water for use in, for example, bath, shower, dishwashing, clothes washing, and flushing toilets. In order to reach the desired temperature the preheated water sometimes needs to be mixed with water of an even higher temperature. This water with an even higher temperature can be heated by, for example, a hot water dispenser. Water heated by the hot water dispenser can be water preheated by the heat exchanger which, is then further heated by the hot water dispenser.

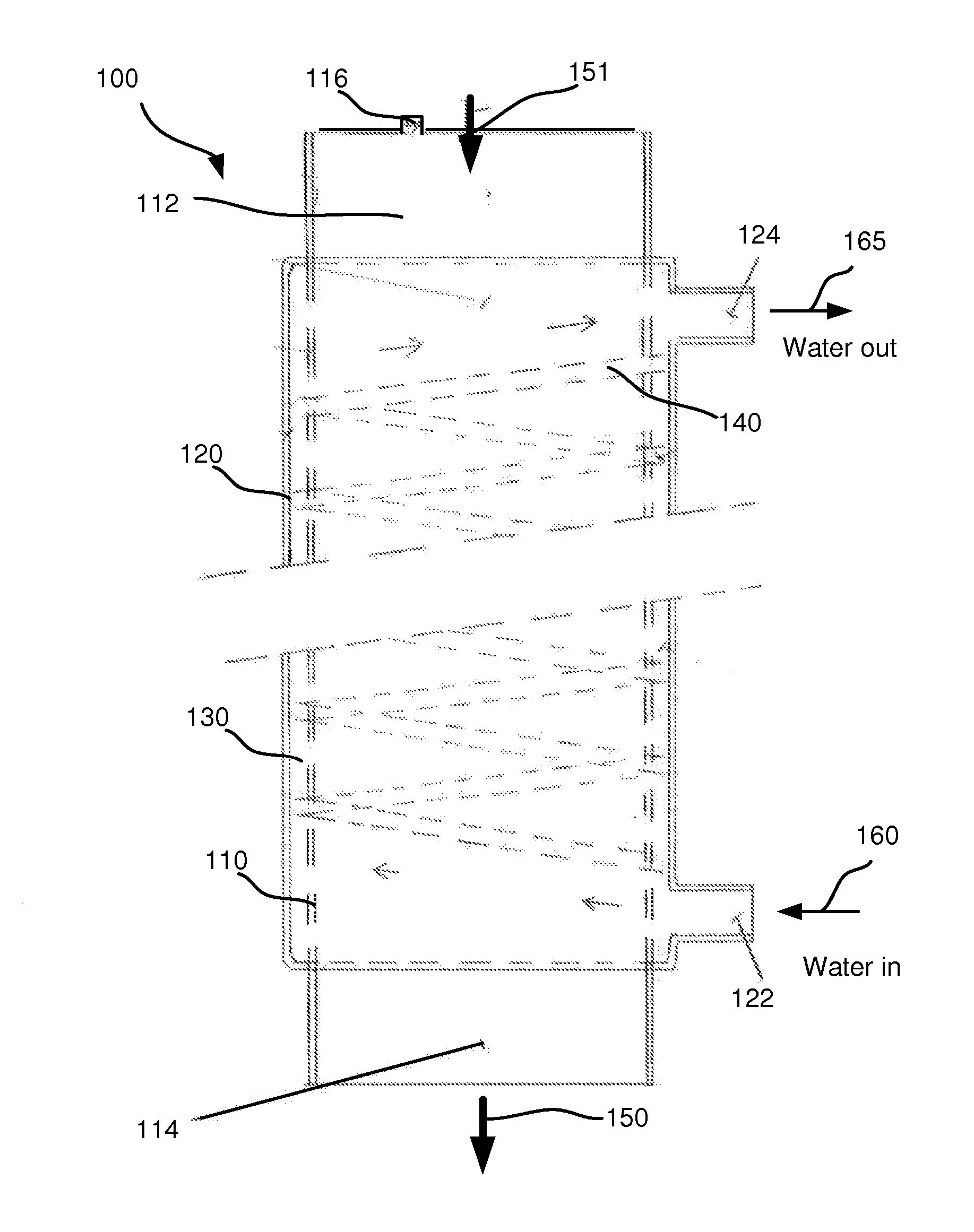

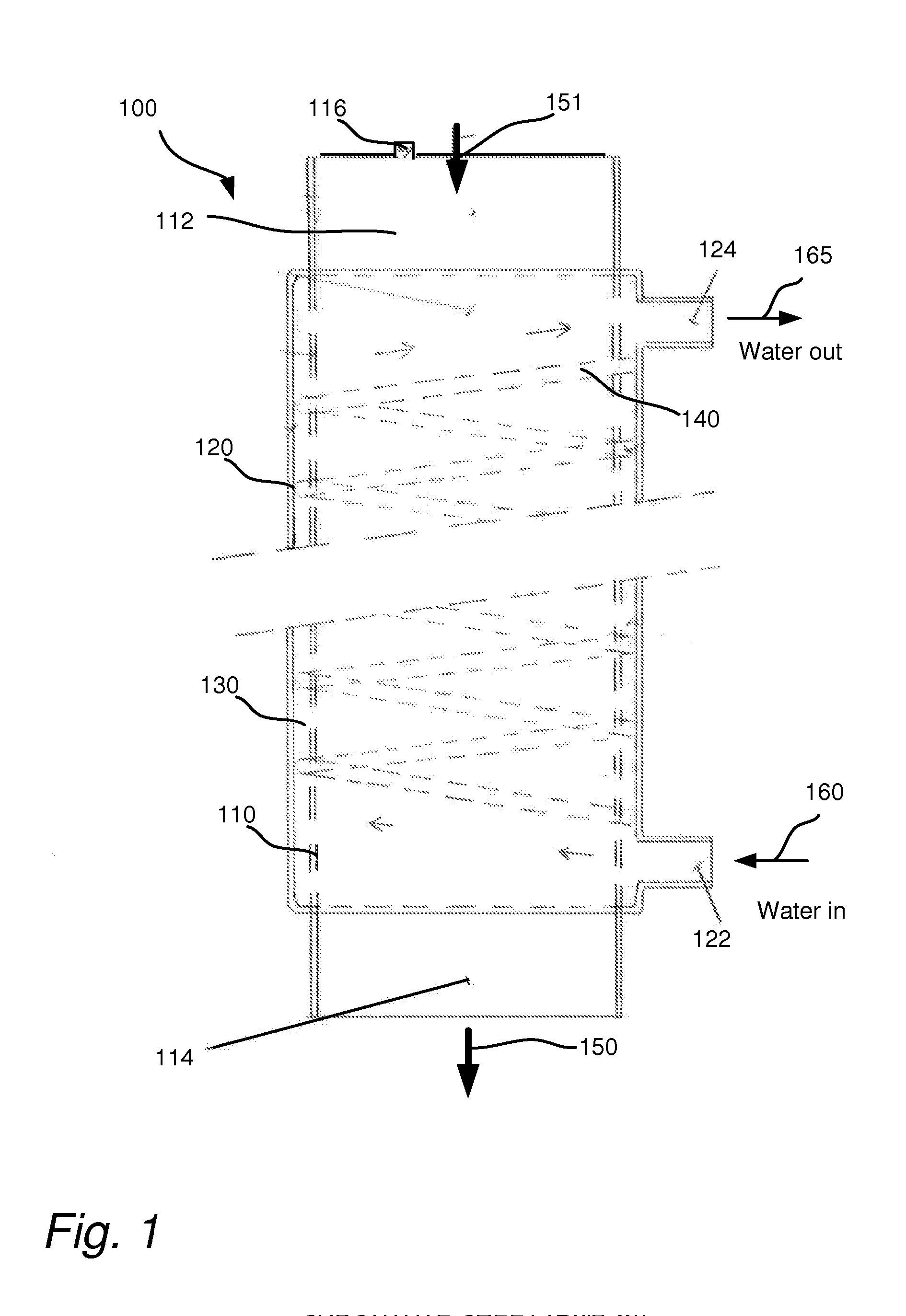

[0047]FIG. 1 shows a cross-section of the heat exchanger according to the invention. Heat exchanger 100 has an inner tube 110 and an outer tube 120. The inner tube 110 is arranged centrally in the outer tube 120. The inner tube 110 is arranged for leading waste water. Waste water is directed downwards in the figure and flows by means of gravitation.

[0048]A space 130 is formed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com