Swirler for a burner of a gas turbine engine, burner of a gas turbine engine and gas turbine engine

a gas turbine engine and burner technology, applied in the direction of burners, combustion types, combustion processes, etc., can solve the problems of unstable flames and high risk of burning, and achieve the effect of easy and cost-effective, high-efficiency carbon build-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

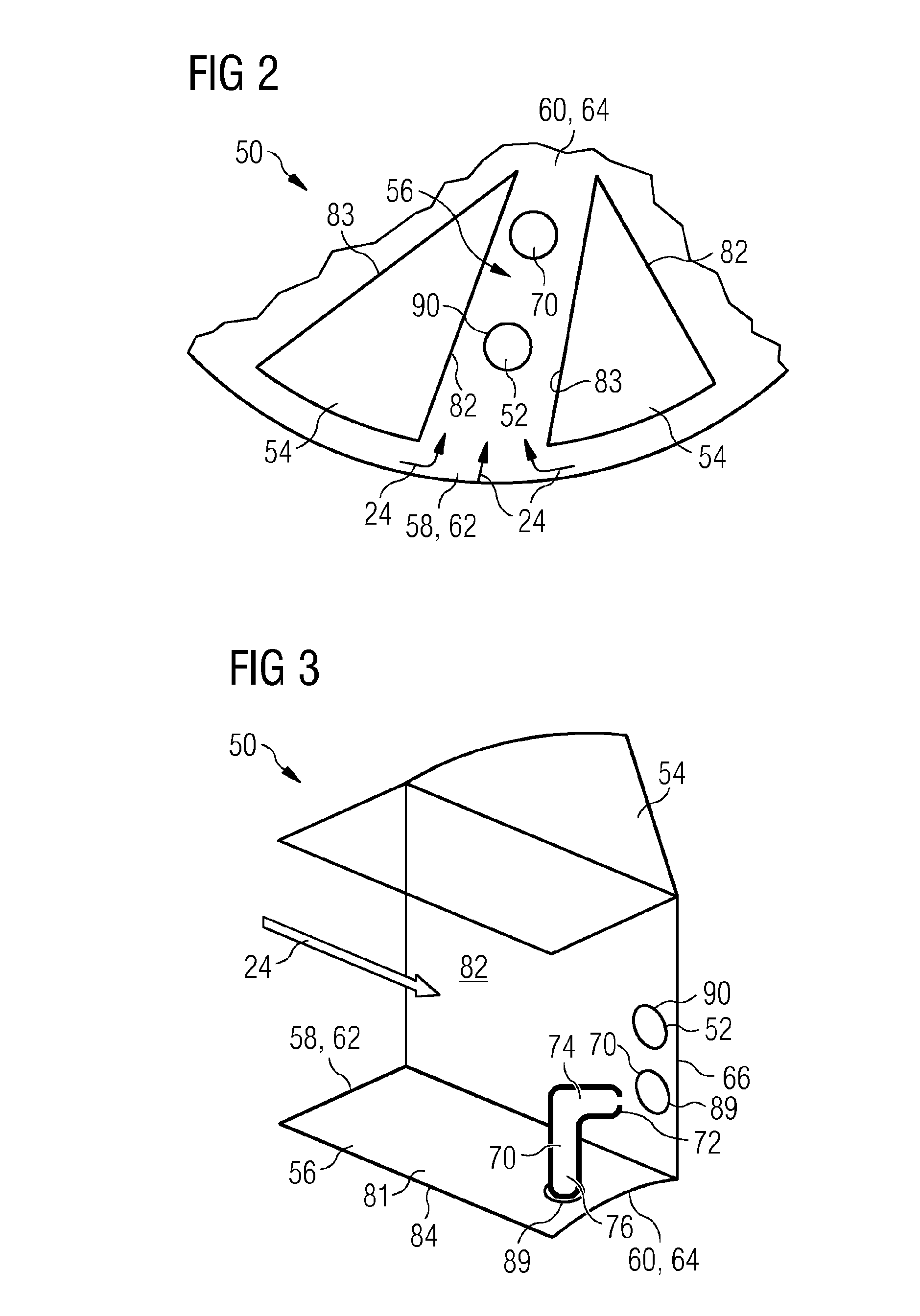

[0037]FIG. 3 shows a side view of a part of a swirler 50 according to the invention. A single vane 54 and the adjacent mixing channel 56 are shown. An arrow symbolizes the air 24 channelled through the mixing channel 56 from its outer end 58 located essentially at the outer radius 62 of the swirler 50 to its inner end 60 located essentially at the inner radius 64 of the swirler 50. Several possible embodiments of a pilot injection means 70 are depicted. One of the pilot injection means 70 is constructed as a fuel injection lance 76. Such a fuel injection lance 76 can advantageously be constructed as a removable fuel injection lance 76. A replacement of the pilot injection means 70 is in this case possible in a very easy manner, especially if the fuel injection lance 76 can be removed from outside of the assembly of the swirler 50.

[0038]Further, the fuel injection lance 76 shown in this figure comprises an angled tip 74. At the end of the angled tip 74 an injection point 72 of this p...

third embodiment

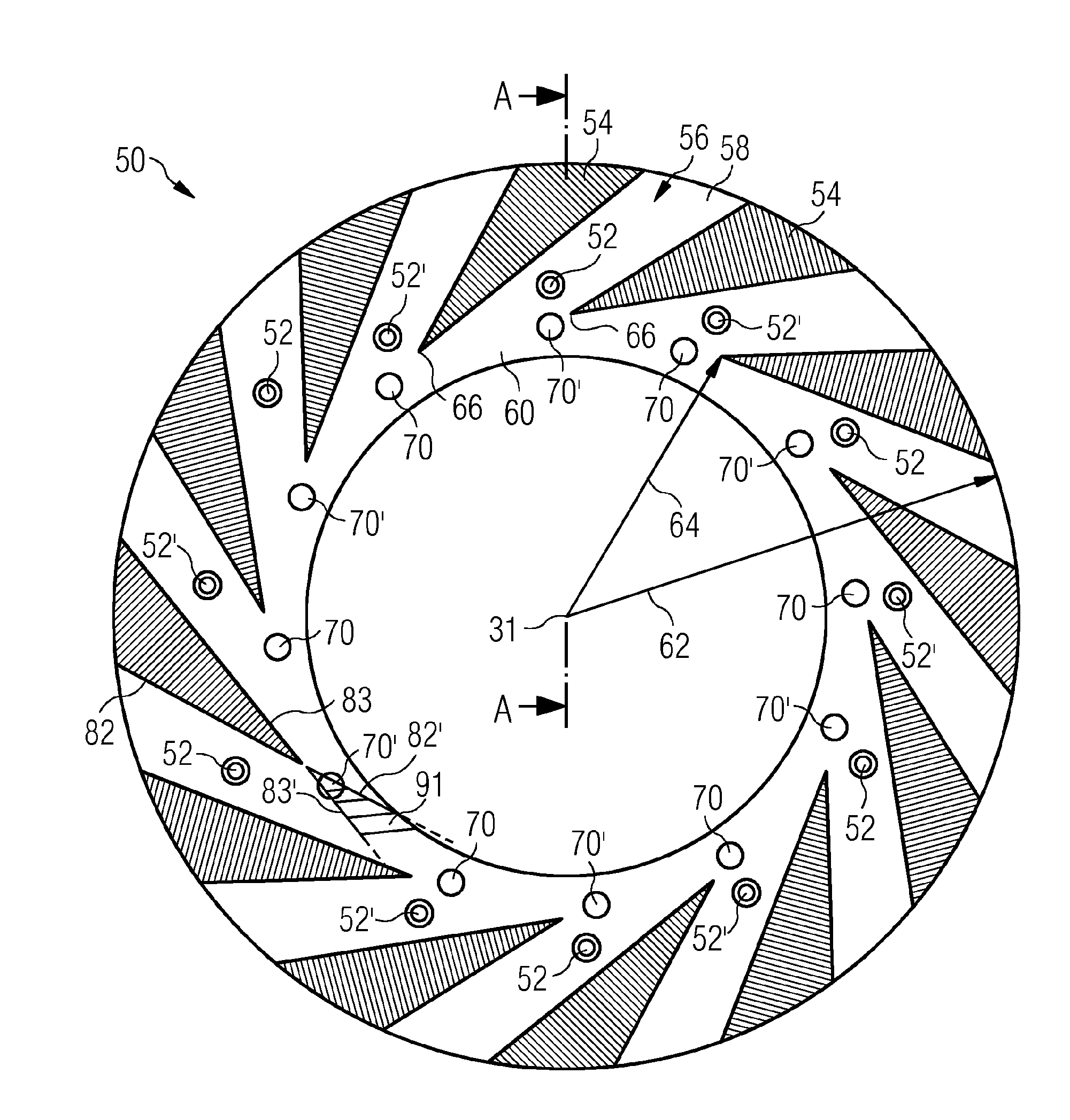

[0039]In FIG. 4 a sectional view of a swirler 50 according to the invention is depicted. The swirler 50 comprises a plurality of vanes 54 extending from an outer radius 64 to an inner radius 62, only two of them marked with reference signs for lucidity. Between the vanes 54 a plurality of mixing channels 56 is located, of which only one is marked with a reference sign for lucidity. The mixing channels extend from an outer end 58 to an inner end 60. In this embodiment of a swirler 50 according to the invention, in each of the mixing channels 56 a main injection means 52 is positioned, each at a slightly different radial position. This contains the advantage that for different operation modes of the gas turbine engine 10 (not shown), for instance different load levels, a special set of main injection means 52, adjusted for instance in total number and / or pattern, can be used.

[0040]Further, at the inner end 60 of each of the mixing channels 56 and near a trailing edge 66 of the vanes 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com