System and method of performing scanning probe microscopy on a substrate surface

a scanning probe and substrate surface technology, applied in the direction of instruments, measurement devices, nanotechnology, etc., can solve the problems of loss of accuracy and the limited scope of the scanning probe device, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

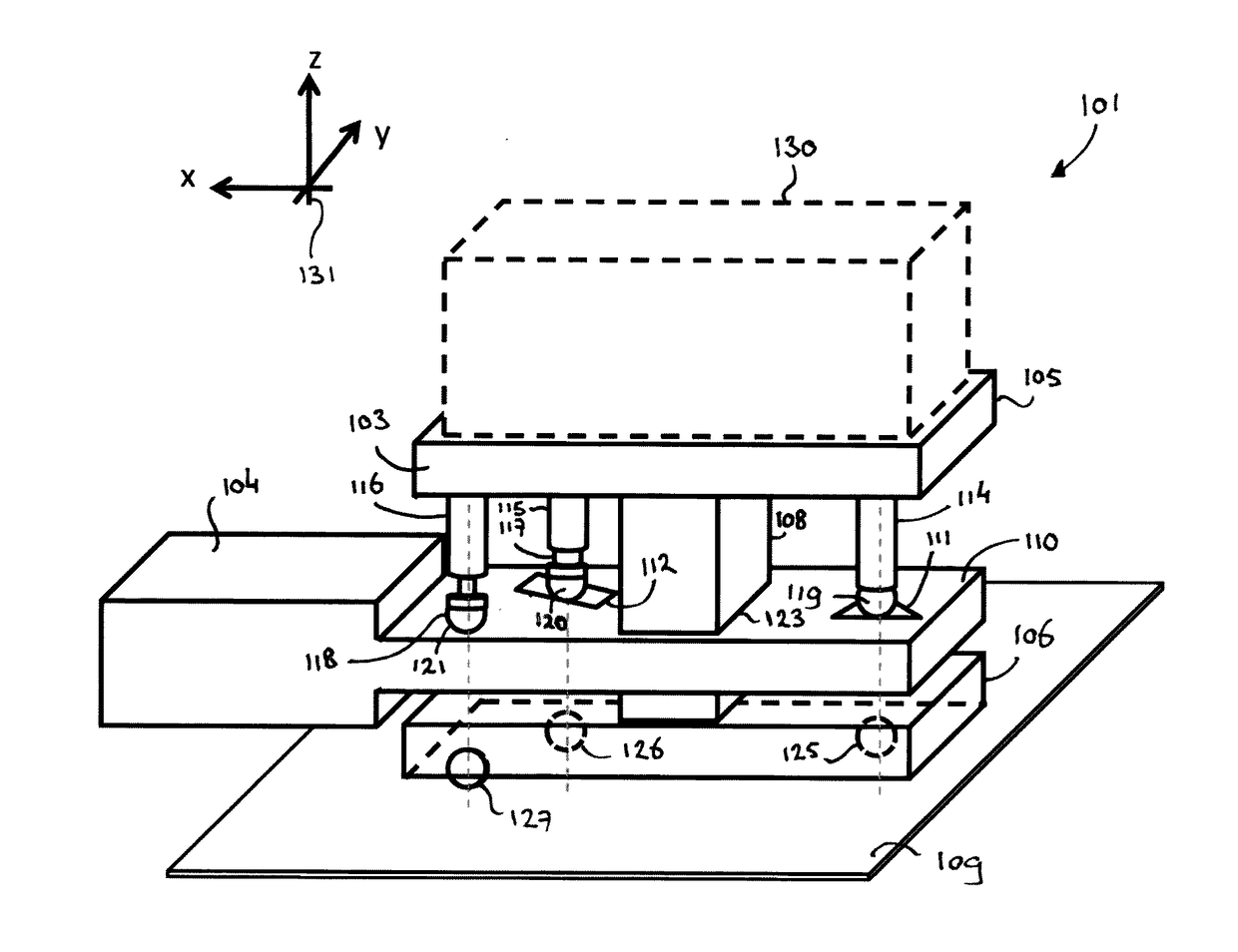

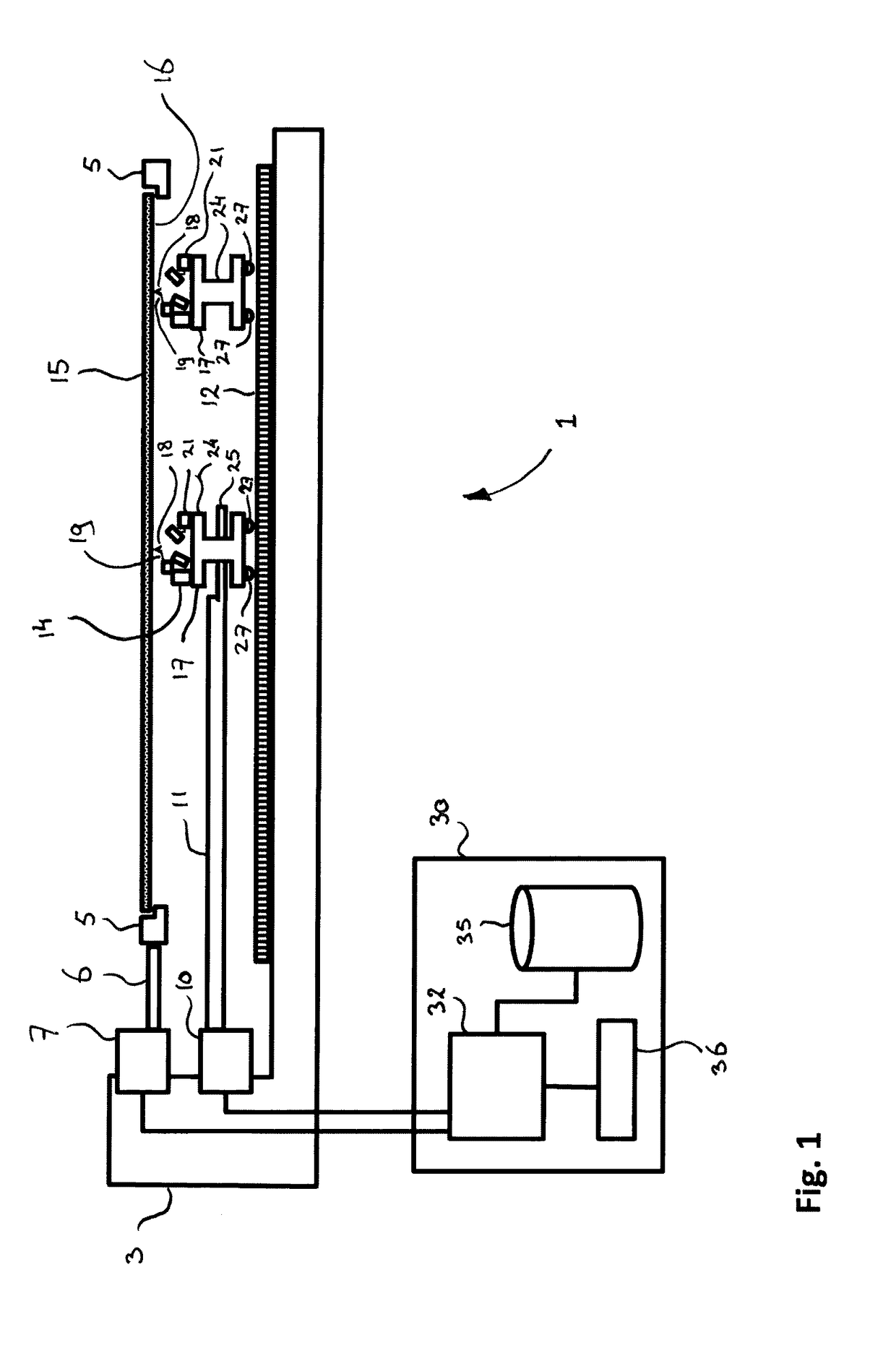

[0030]FIG. 1 schematically illustrates a scanning probe microscopy (SPM) system 1 of the present invention. The SPM system 1 is suitable for being used in combination with the method of performing scanning probe microscopy in accordance with the present invention. The SPM system 1 comprises a metrology frame 3. The metrology frame provides a solid fixed base for the system. For obtaining the desired accuracy, the metrology frame is preferably kept free from any vibrations, and ideally also temperature changes within or in the environment of the metrology frame 3 are ruled out as much as possible.

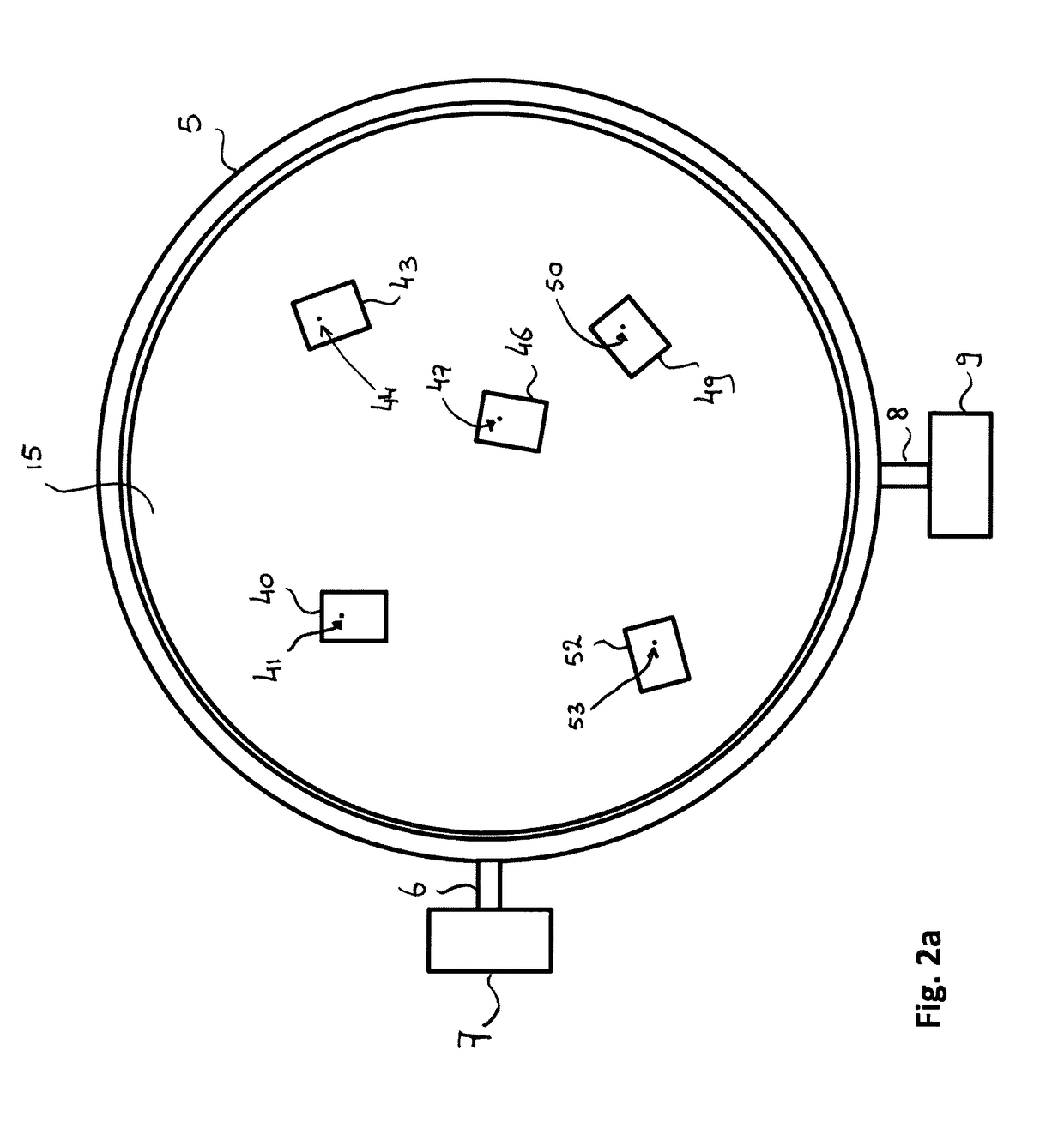

[0031]A substrate holder 5 for carrying a substrate 15 such as a wafer, is connected to an XY substrate holder actuator 7 by means of a substrate holder arm 6.

[0032]The substrate holder actuator 7 may be a system that allows to move the substrate holder 5, and therewith the substrate 15, in the X and Y directions, i.e. the directions parallel to the substrate 15. In FIG. 1, the substrate hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com