A guide vane made of composite material for a gas turbine engine, and it's method of fabrication

a gas turbine engine and composite material technology, applied in the direction of machines/engines, efficient propulsion technologies, other domestic articles, etc., can solve the problems of high cost, long time-consuming and labor-intensive, and the method of fabricating the guide vanes suffers from certain drawbacks, so as to increase the stiffness of the airfoil, limit the asymmetries of stiffness and shrinkage, and increase the effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The invention applies to making guide vanes for a gas turbine aeroengine, each vane having a leading edge.

[0032]Non-limiting examples of such guide vanes include in particular outlet guide vanes (OGV), inlet guide vanes (IGV), and variable stator vanes (VSV), etc.

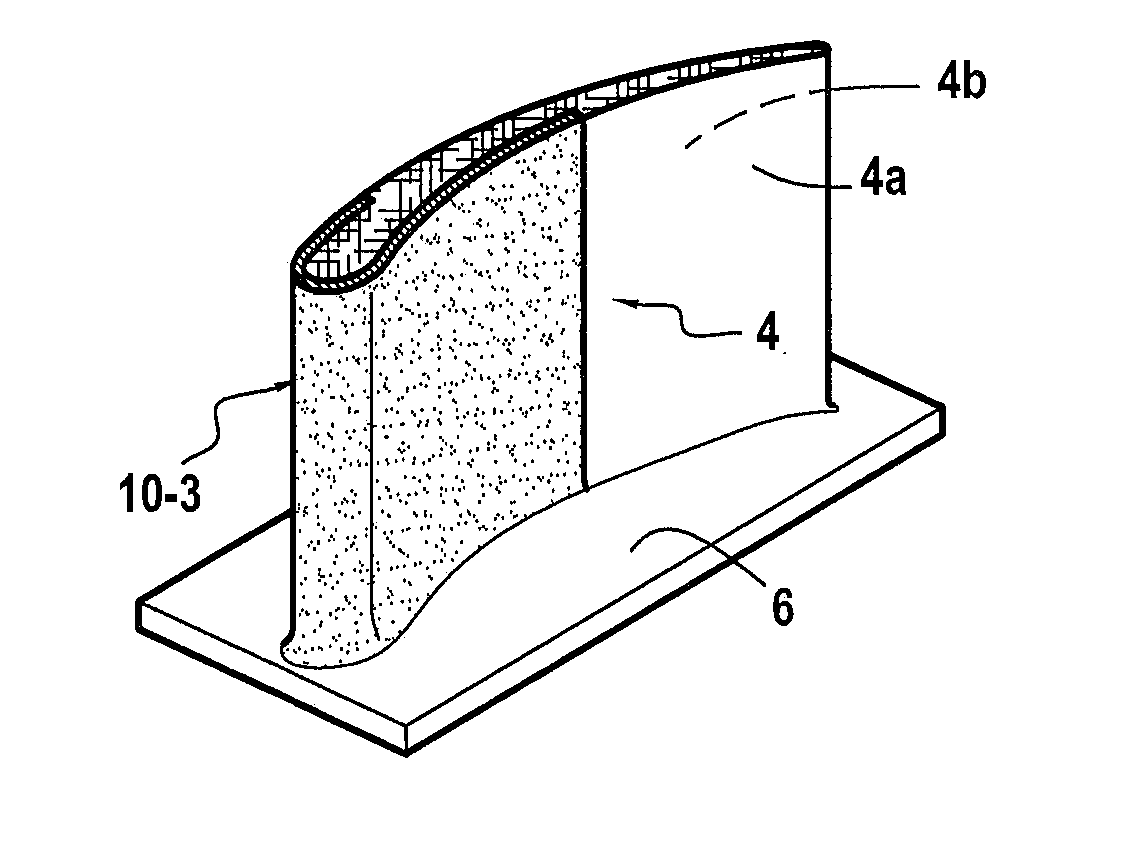

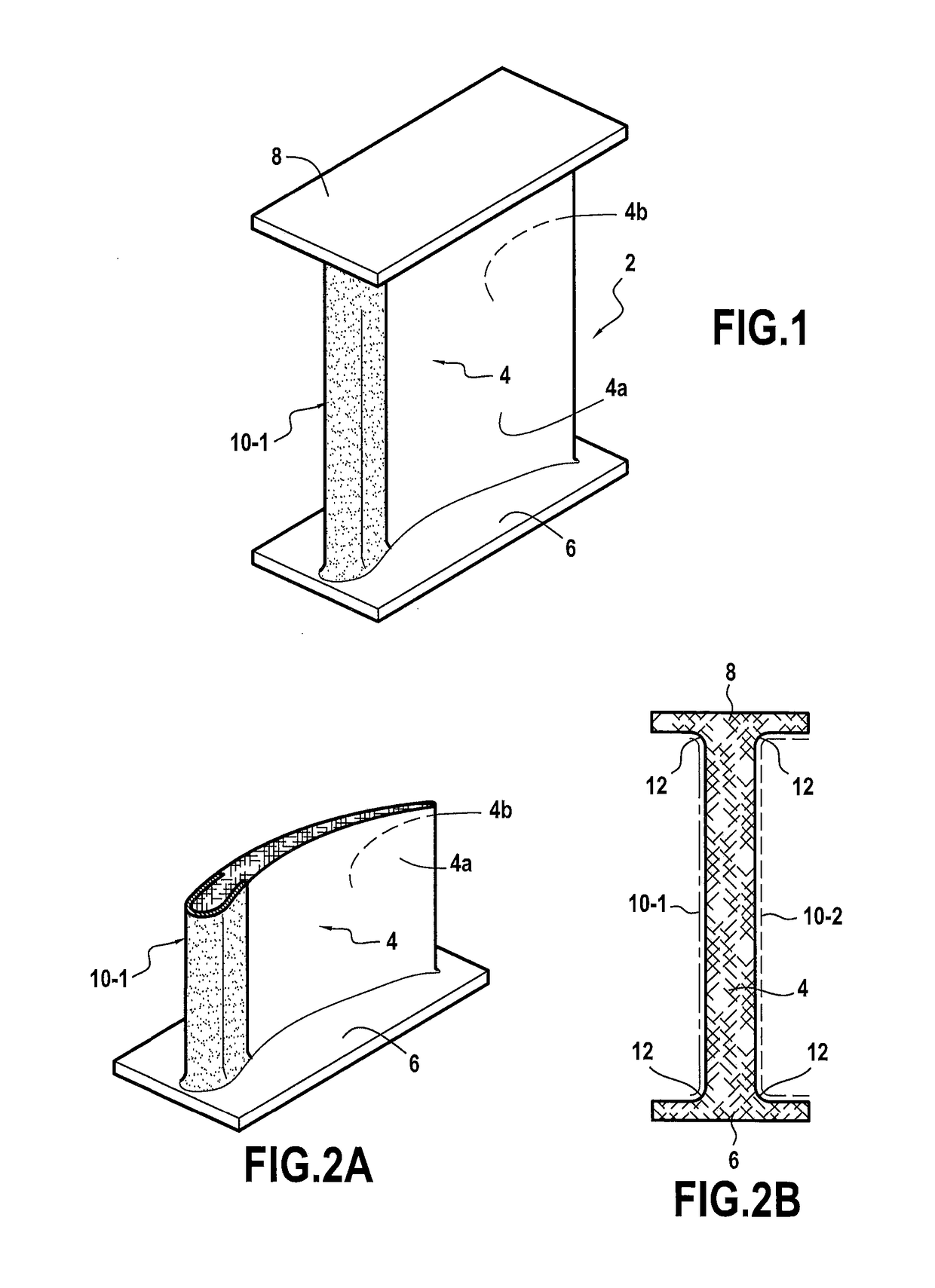

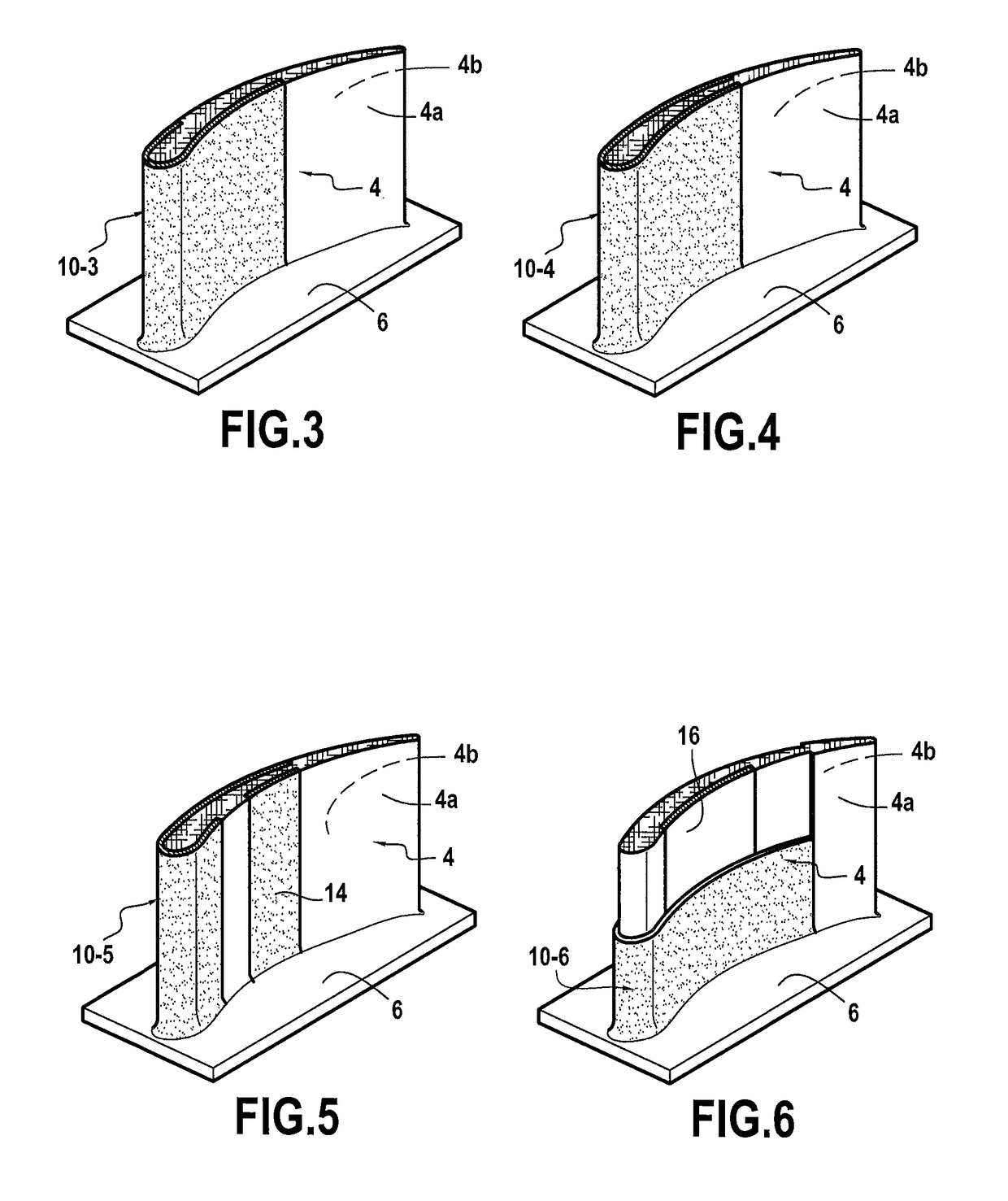

[0033]FIG. 1 is a diagrammatic perspective view showing an example of such a guide vane 2.

[0034]In known manner, the guide vane 2 comprises an airfoil 4 having a pressure side face 4a and a suction side face 4b, an inner platform 6 that is assembled on a radially inner end of the airfoil, and an outer platform 8 that is assembled on the radially outer end of the airfoil.

[0035]In accordance with the invention, the airfoil 4 is made of composite material having fiber reinforcement densified by a matrix, the fiber reinforcement being obtained from pre-impregnated long fibers, e.g. discontinuous fibers that are agglomerated in the form of a mat. The fabrication of such an airfoil is described below.

[0036]In the same manne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com