Scrubber tower of a flue gas purification device

a technology of flue gas purification and scrubber tower, which is applied in the direction of distillation separation, separation machines, mixing methods, etc., can solve the problems that gas purification does not meet the corresponding economical and ecological demands any more, and achieve the effect of enlarging or reducing the size of means/inserts, enlarging or reducing the size of adjacent construction elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

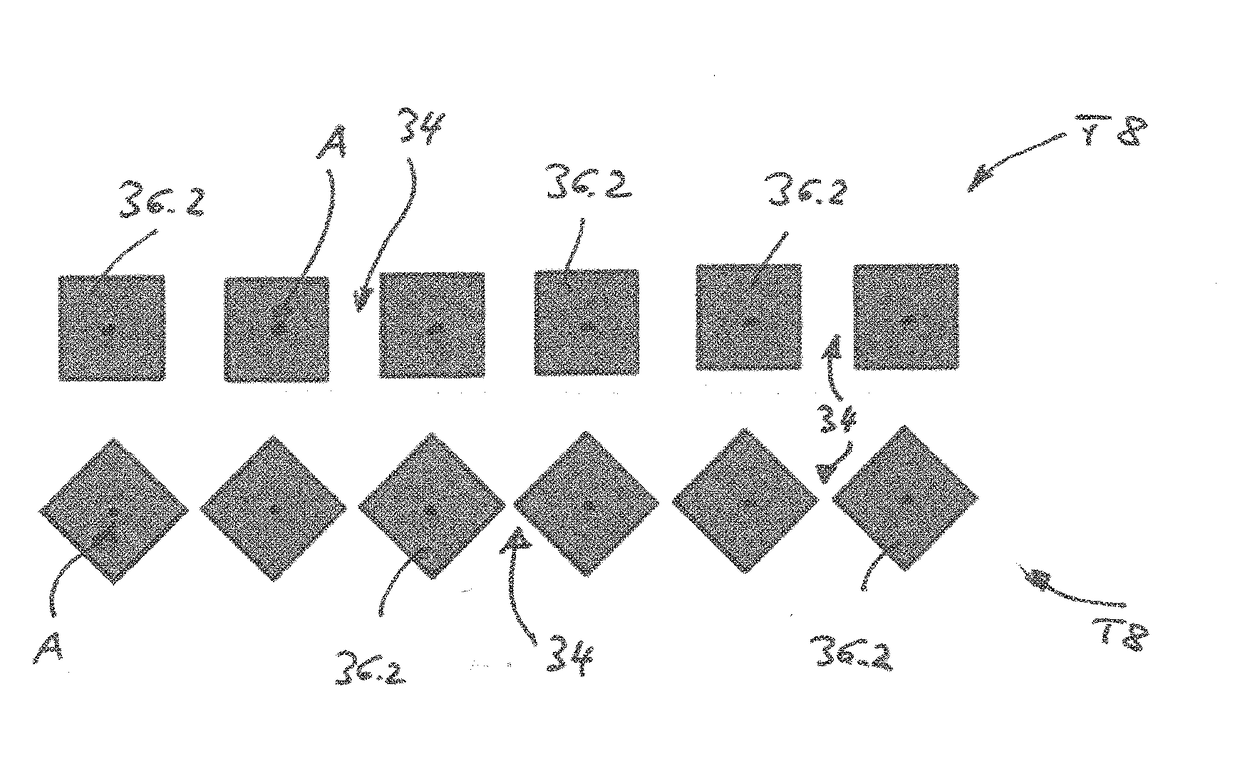

[0065]FIG. 1 represents the main features of a scrubber tower 10 by which a flue gas from an associated power station (not illustrated) will be purified.

[0066]Scrubber tower 10 comprises a cylindrical outer wall 10w, a flue gas entrance 12 at a lower part 10l and a flue gas exit 14 at an upper part 10u, a liquid (seawater) entrance 18 at said upper part 10u and a liquid exit 20 at said lower part 10l. Said liquid exit 20 corresponds to a so called sump area beneath the lower part 10l of scrubber tower 10. The return line to the sea is marked by arrow M.

[0067]The liquid is fed into the cylindrical space of scrubber tower 10 via nozzles 18n, attached to said liquid inlet pipe 18. The seawater absorbent further takes its way downwardly (arrow A) within scrubber tower 10 (following gravity), thereby getting in contact with said flue gas flowing upwardly (arrow G) in said scrubber tower 10 (the flue gas flow is generated by a—non-illustrated—fan).

[0068]The corresponding counter flow area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com