Cap with a cutting element

a technology of cutting element and cap, applied in the field of packaging technology, can solve the problems of dramatic hammering of the quality of the product, and achieve the effect of convenient initial arrangement and adequate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

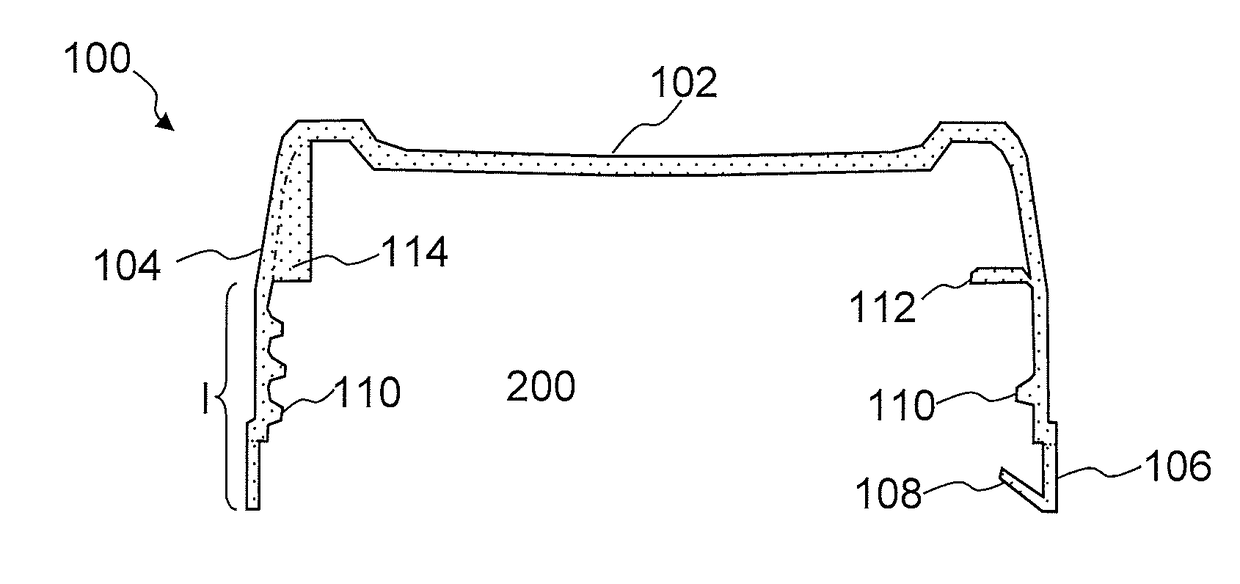

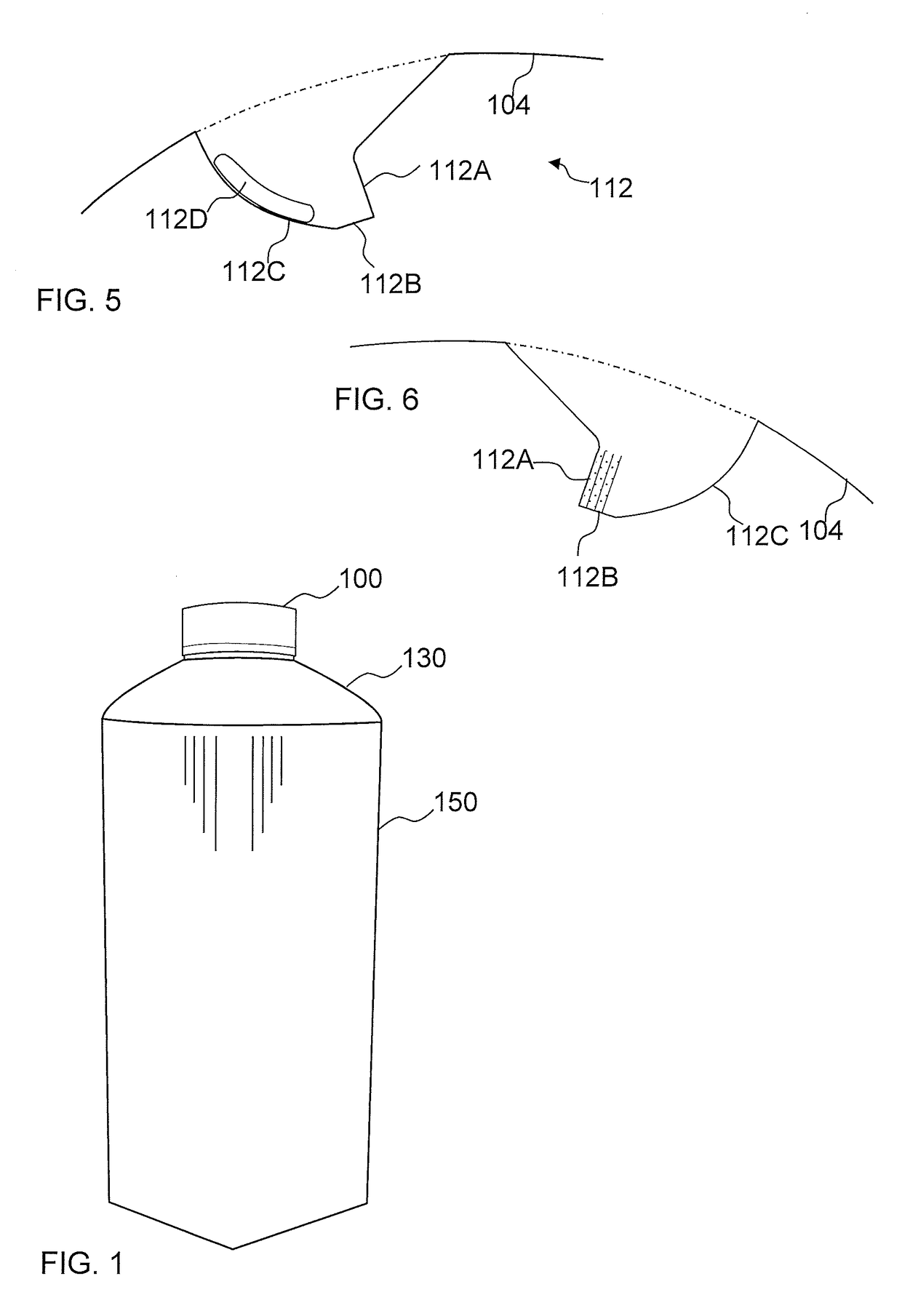

[0028]To put the present invention into context a packaging container is shown in the perspective view of FIG. 1. This is a type of packaging container which may utilize an cap according to the present invention. It should be noted that an inventive cap, inventive neck, etc may be used in combination with other packaging containers too. Returning to the packaging container of FIG. 1, it is composed of three constructional parts. A sleeve 150 is attached to a shoulder / neck portion 130, and a cap 100 is arranged on the neck. It is a typical example of a Tetra Top® container, which is a well known carton bottle concept from the present applicant. The shoulder / neck portion 130 is moulded in one piece directly onto the sleeve 150, after which a cap 100 is screwed onto the neck. The sleeve 150 is formed from a packaging laminate of standard design, i.e. a paper core with surrounding laminate layers also well known in prior art.

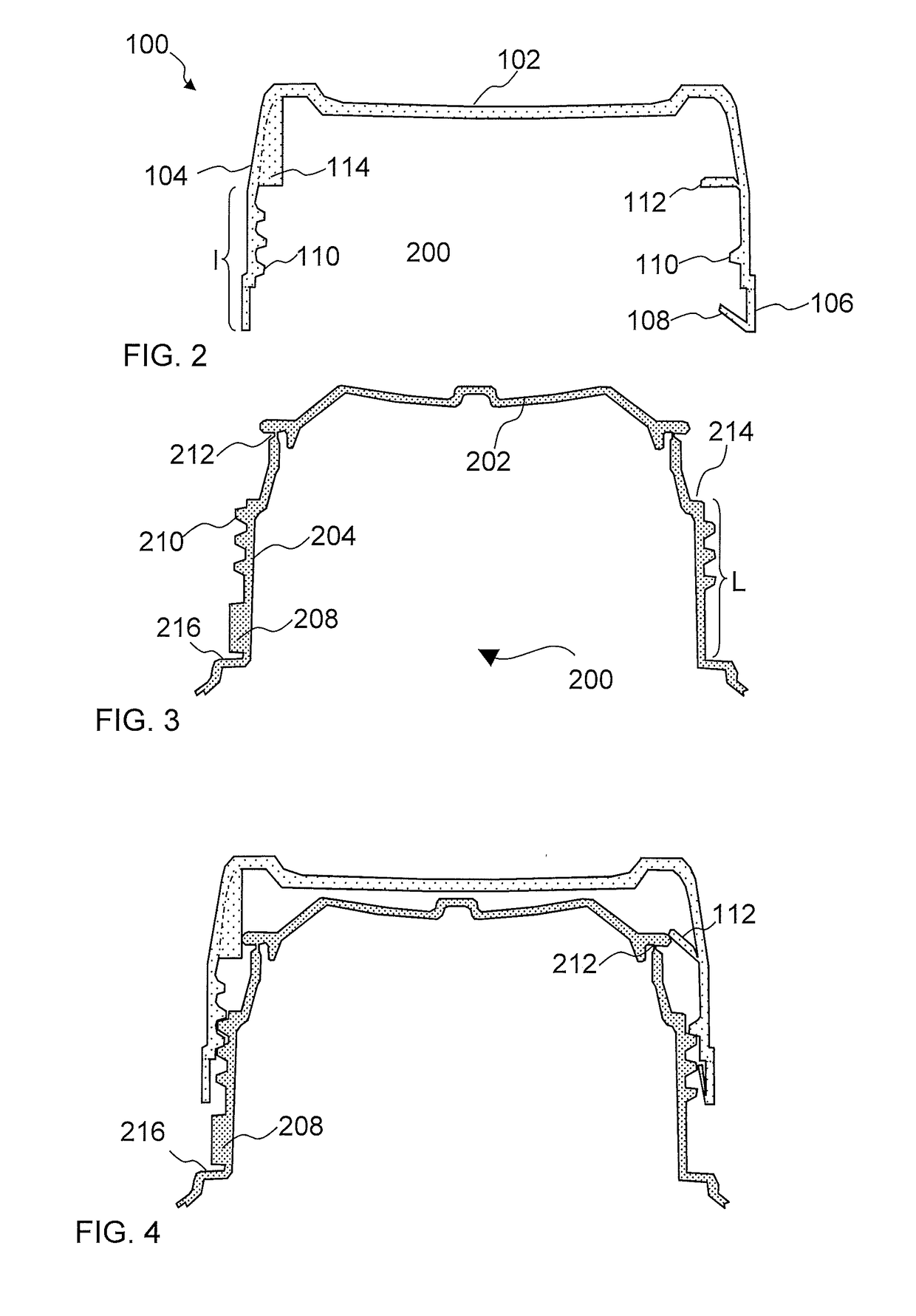

[0029]FIGS. 1 and 2 illustrates a cap and a neck respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com