Online tracer monitoring and tracer meter

a tracer and monitoring technology, applied in the field of tracer monitoring and tracer meter, can solve the problems of consuming time and laborious, and reducing the number of fluid samples to be analyzed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059]In the following the invention will be described with references to, but not limited to illustrations in the attached figures.

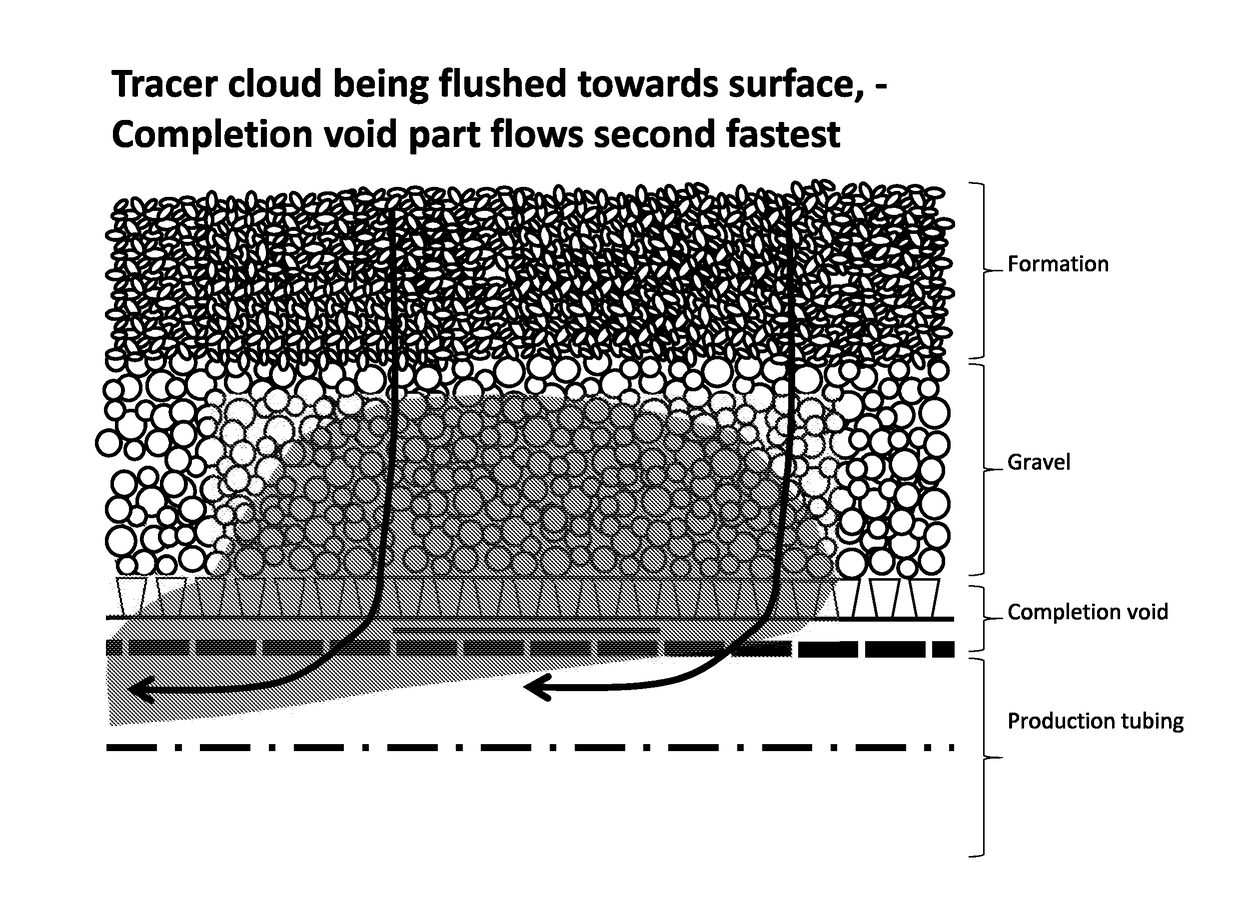

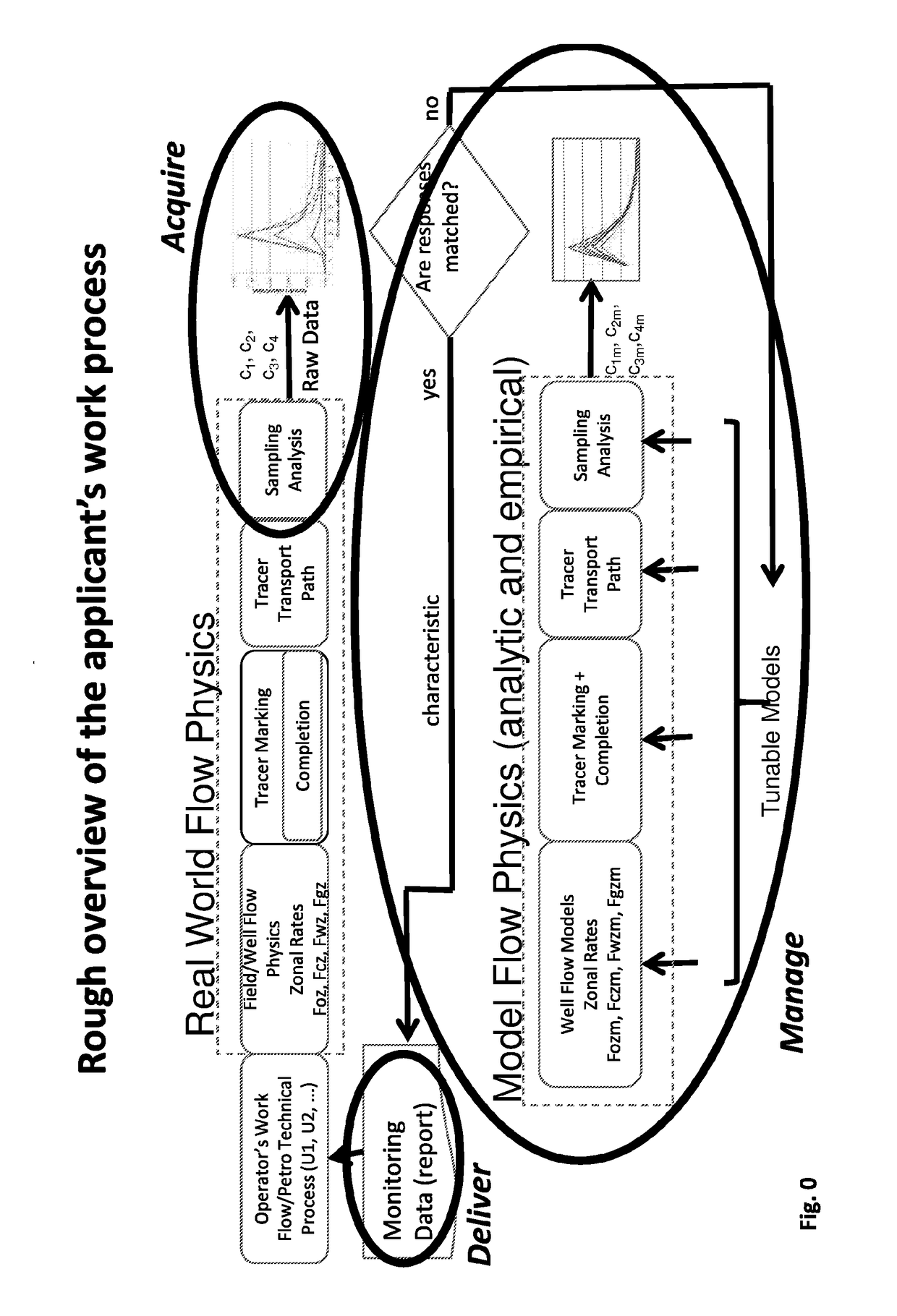

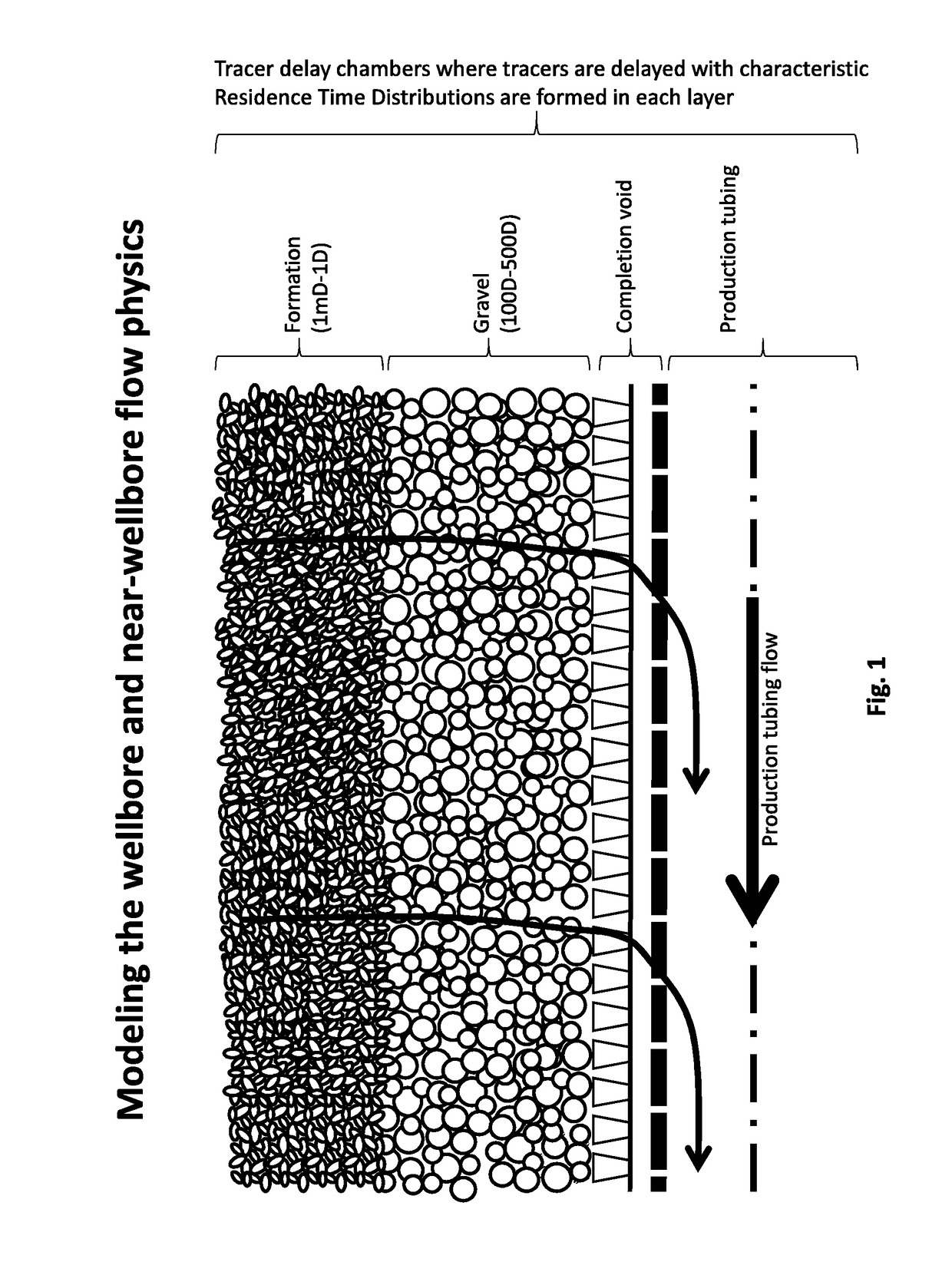

[0060]The applicants work process is related to ACQUIRE and MANAGE raw zonal tracer flux data and finally DELIVER usable information to customers. This invention relates to the ACQUISITION and a method and an apparatus for high frequency online monitoring of zonal tracer flux of oil-, condensate-, gas-, or water-following tracers in a production flow in a petroleum well so as for detecting tracer concentrations that corresponds to so-called “ultra-high frequency” zonal tracer flux signals.

[0061]The invention is a tracer method for online monitoring of downhole zonal contributions of oil, condensate, gas, or water mass flux (Foz, Fcz, Fwz, Fgz) of a production flow (2) in a petroleum production well (1), comprising

[0062]a) arranging distinct tracer carrier systems (Trs1, Trs2, . . . ) each in different production zones (Z1, Z2, . . . ) in said well (1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com